Bismuth-bismuth tungstate- bismuth oxybromide ternary composite and preparation method and application thereof

A ternary compound, bismuth oxybromide technology, applied in alkali metal compounds, chemical instruments and methods, water treatment of special compounds, etc., can solve the problem that the quantum yield does not meet expectations, achieve strong adsorption and visible light degradation, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

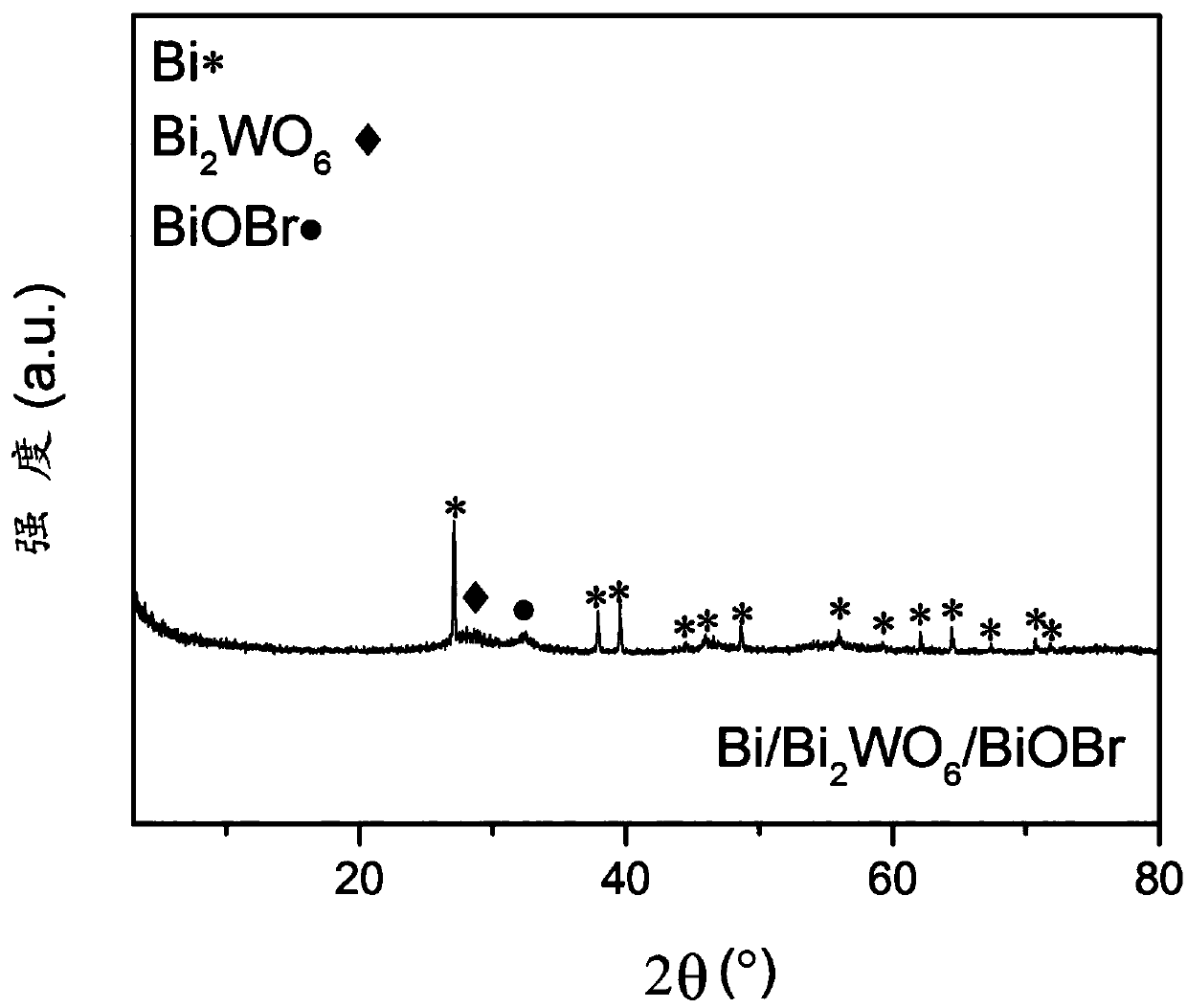

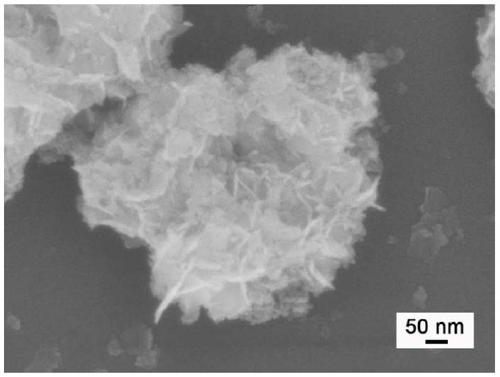

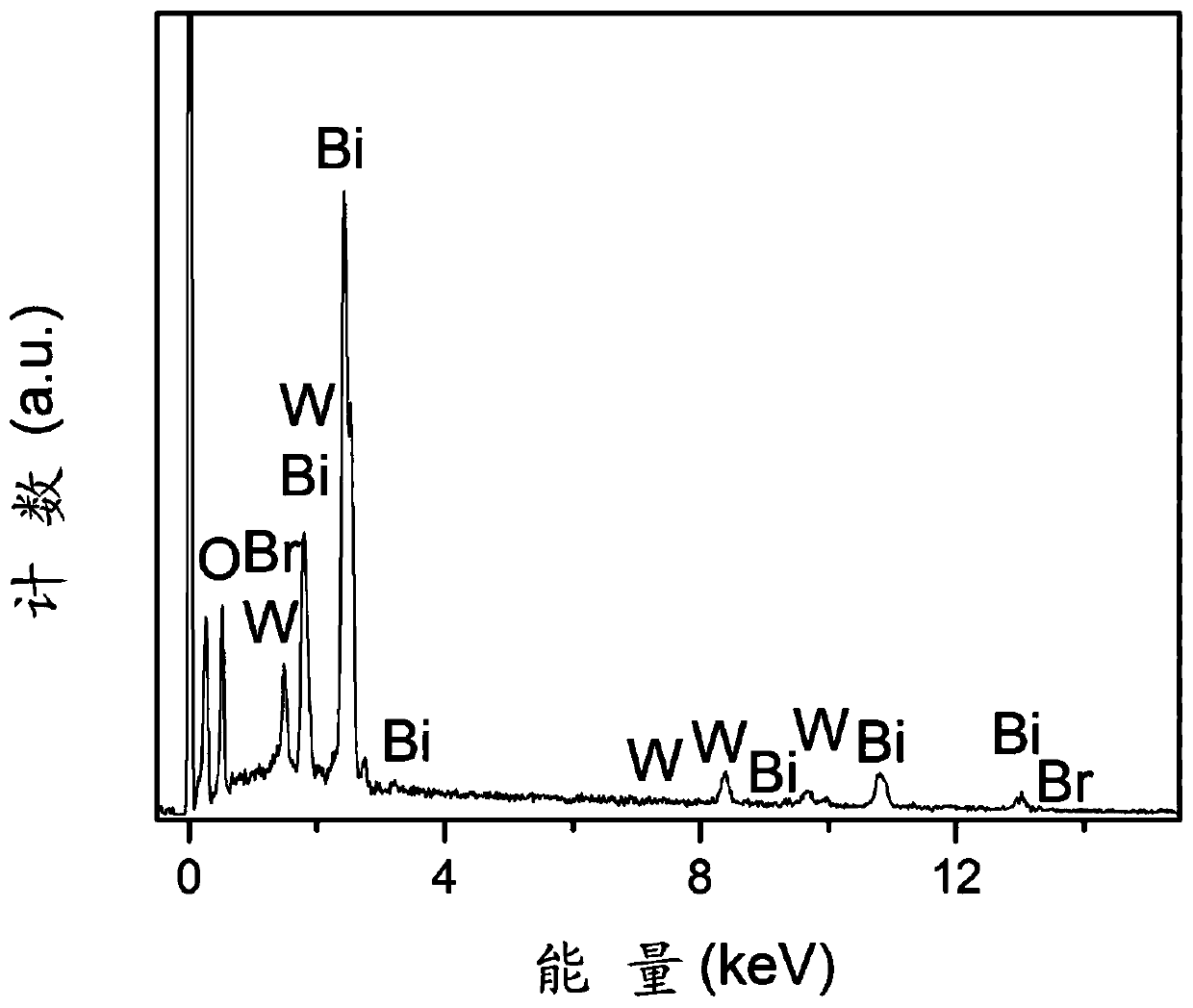

[0047] Preparation of Bismuth-Bismuth Tungstate-Bismuth Oxybromide Ternary Composite

[0048] (1) preparation concentration is the bismuth nitrate ethylene glycol solution A of 0.1M;

[0049] (2) Prepare a sodium tungstate glycol solution with a concentration of 0.05M so that the molar ratio of bismuth nitrate and sodium tungstate is 2:1; then add potassium bromide so that the molar ratio of sodium tungstate and potassium bromide is 1:0.5, after stirring evenly, the ethylene glycol solution B of sodium tungstate and potassium bromide is obtained;

[0050] (3) Slowly add the ethylene glycol solution B of sodium tungstate and potassium bromide dropwise to the ethylene glycol solution A of bismuth nitrate, control the dropping time for 10 minutes, and then stir for 10 minutes to obtain a uniform mixed solution;

[0051] (4) Transfer the mixed solution to a polytetrafluoroethylene liner with a steel jacket, place it in an oven for solvothermal reaction, the reaction temperature i...

Embodiment 2

[0064] Preparation of Bismuth-Bismuth Tungstate-Bismuth Oxybromide Ternary Composite

[0065] (1) preparation concentration is the bismuth nitrate ethylene glycol solution A of 1M;

[0066] (2) Prepare a sodium tungstate glycol solution with a concentration of 0.5M, so that the molar ratio of bismuth nitrate and sodium tungstate is 2:1; then add potassium bromide, so that the molar ratio of sodium tungstate and potassium bromide is 1:5, after stirring evenly, the ethylene glycol solution B of sodium tungstate and potassium bromide is obtained;

[0067] (3) Slowly add the ethylene glycol solution B of sodium tungstate and potassium bromide dropwise to the ethylene glycol solution A of bismuth nitrate, control the dropping time for 40 minutes, and then stir for 60 minutes to obtain a uniform mixed solution;

[0068] (4) Transfer the mixed solution to a polytetrafluoroethylene liner with a steel jacket, place it in an oven for solvothermal reaction, the reaction temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com