Erythrocyte membrane coated bionic blood hexavalent chromium reduction remover/magnetic nanomotor and preparation method and application thereof

A red blood cell membrane and magnetic nanotechnology, applied in the field of biomedical materials, can solve problems such as poor biocompatibility, achieve protective activity, improve biocompatibility, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

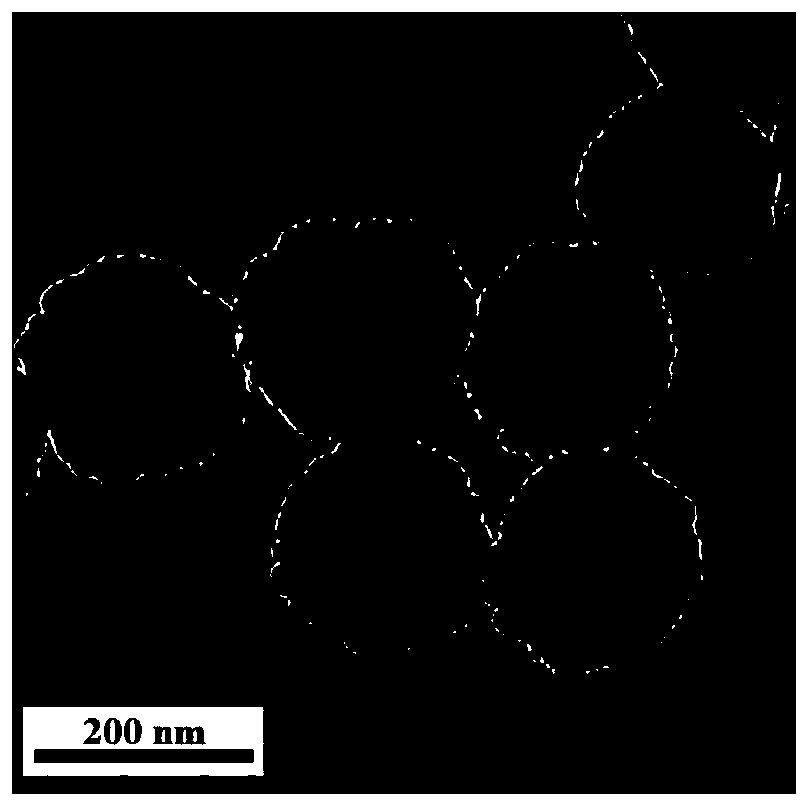

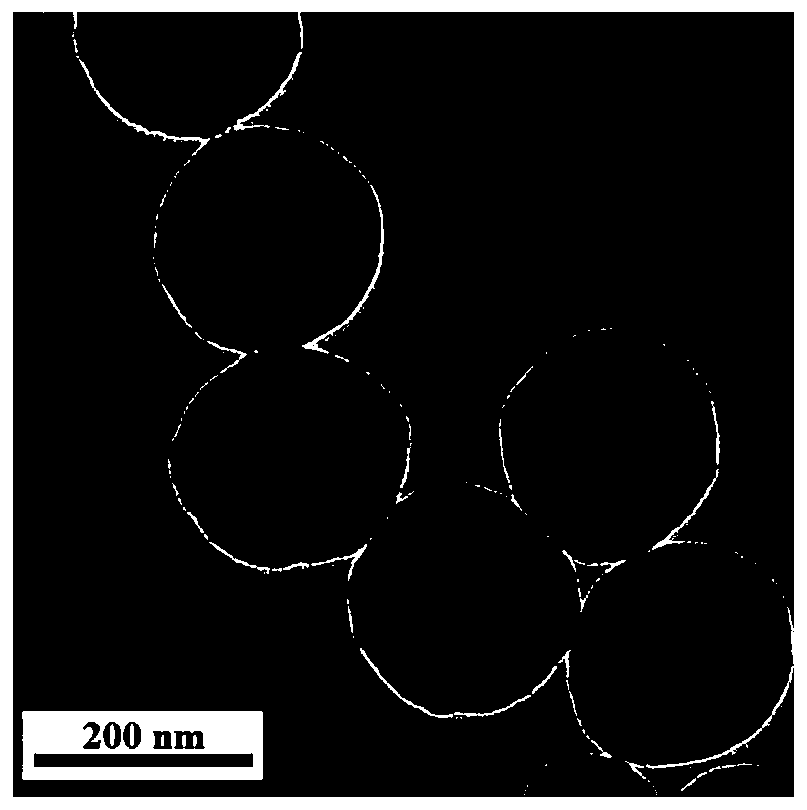

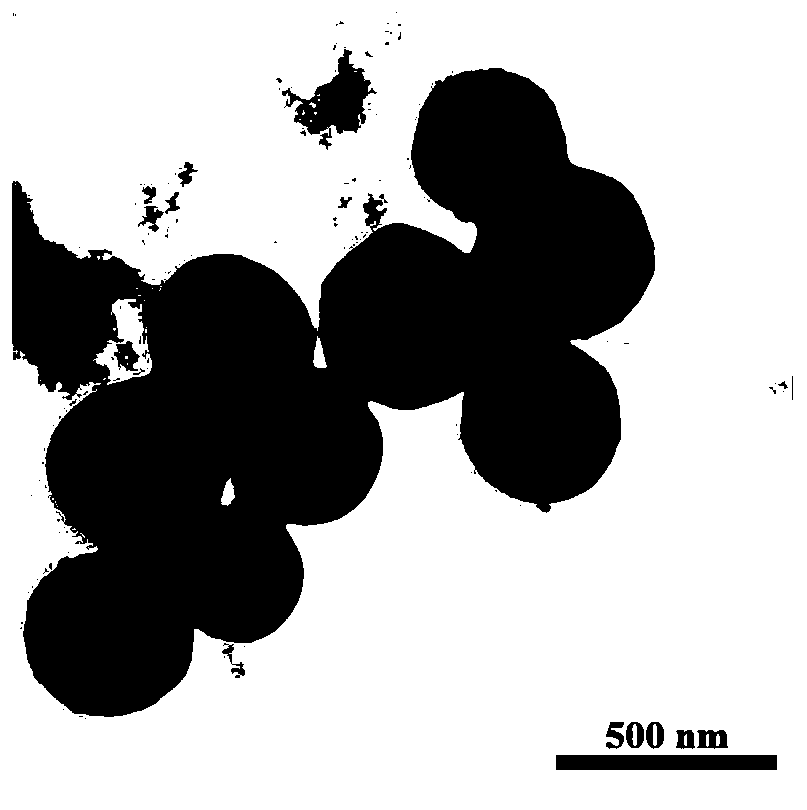

[0043] Hydrothermal Synthesis of Fe 3 o 4 NPs. Weigh 2.7g (10mmol) of ferric trichloride hexahydrate and fully dissolve it in 80mL of ethylene glycol. 7.2 g of sodium acetate and 0.9 g of sodium citrate were added with stirring. Stirring was continued for 30 min, and the mixture was transferred to a high-temperature reactor at 200° C. for 20 h. After natural cooling, the product was washed several times with deionized water and ethanol successively by magnetic separation method, and the product was vacuum-dried at 60°C. Magnetic Fe 3 o 4 NPs transmission electron microscopy such as figure 1 As shown, the size is about 200nm.

[0044] Weigh 150mg Fe 3 o 4 Disperse in 90mL of water, add 1.5mL of hydrazine hydrate solution (50%) to it, and after ultrasonication for 30min, add 210mL of water to it to make the pH of the solution = 9-10, continue to drop 96μL of TEOS into the solution, and stir at 90°C After reacting for 2 hours, the product was washed with water three tim...

Embodiment 2

[0050] Hydrothermal Synthesis of Fe 3 o 4 NPs. Weigh 2.7g (10mmol) of ferric trichloride hexahydrate and fully dissolve it in 80mL of ethylene glycol. 7.2 g of sodium acetate and 0.9 g of sodium citrate were added with stirring. Stirring was continued for 30 min, and the mixture was transferred to a high-temperature reactor at 150° C. for 25 h. After natural cooling, the product was washed several times with deionized water and ethanol successively by magnetic separation method, and the product was vacuum-dried at 60°C. Weigh 150mg Fe 3 o 4 Disperse in 90mL of water, add 1.5mL of hydrazine hydrate solution (50%) to it, and after ultrasonication for 30min, add 210mL of water to it to make the pH of the solution = 9-10, continue to add 96μLTEOS dropwise to the solution, and stir at 90°C for reaction After 2 hours, the product was washed with water three times by magnetic separation. Continue to disperse the solid product in 210mL water, add 2.4mL hydrazine hydrate and 0.4...

Embodiment 3

[0055] Hydrothermal Synthesis of Fe 3 o 4 NPs. Weigh 2.7g (10mmol) of ferric trichloride hexahydrate and fully dissolve it in 80mL of ethylene glycol. 7.2 g of sodium acetate and 0.9 g of sodium citrate were added with stirring. Stirring was continued for 30 min, and the mixture was transferred to a high-temperature reactor at 250° C. for 15 h. After natural cooling, the product was washed several times with deionized water and ethanol successively by magnetic separation method, and the product was vacuum-dried at 60°C. Weigh 150mg Fe 3 o 4 Disperse in 90mL of water, add 1.5mL of hydrazine hydrate solution (50%) to it, and after ultrasonication for 30min, add 210mL of water to it to make the pH of the solution = 9-10, continue to add 96μLTEOS dropwise to the solution, and stir at 90°C for reaction After 2 hours, the product was washed with water three times by magnetic separation. Continue to disperse the solid product in 210mL water, add 2.4mL hydrazine hydrate and 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com