Spherical covalent organic framework material, preparation method and application thereof

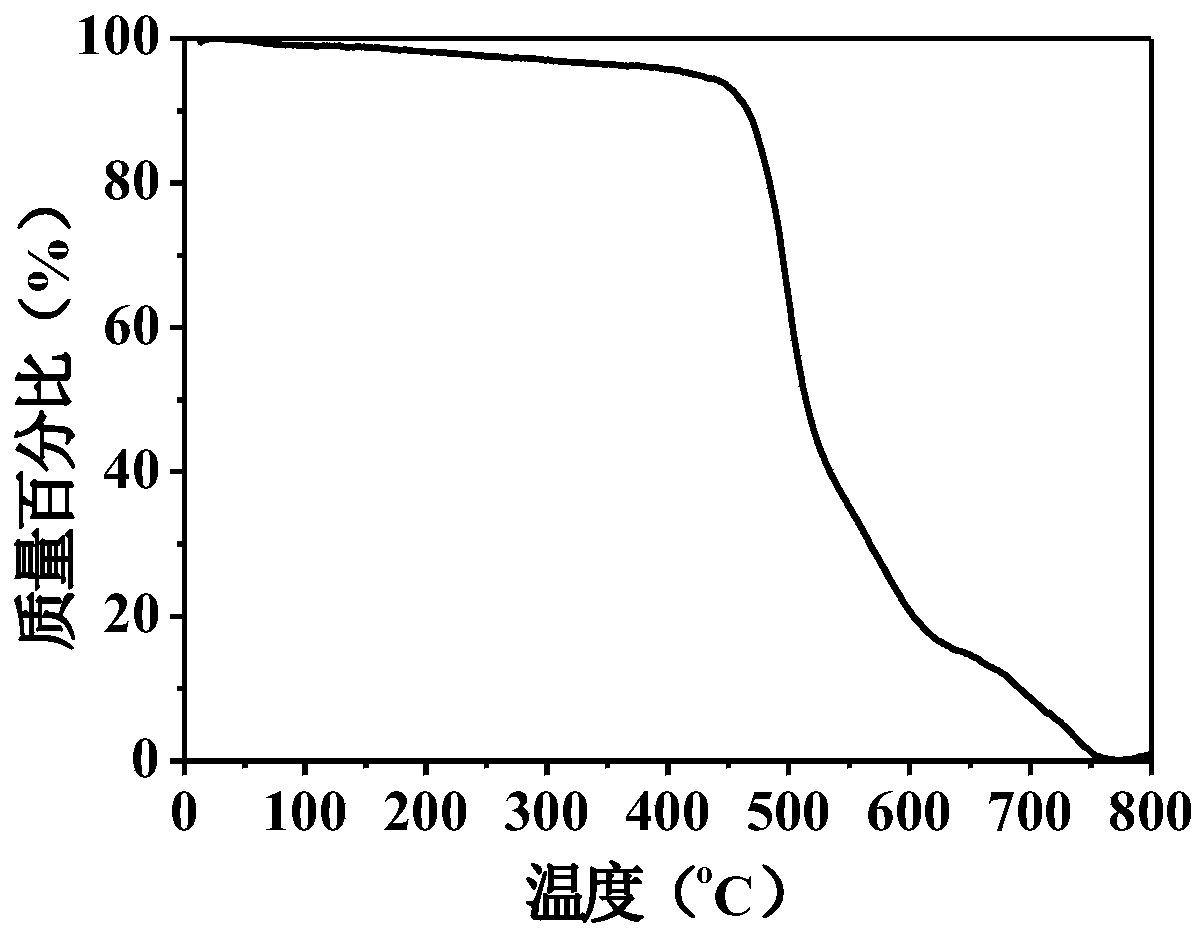

A covalent organic framework, spherical technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of easy introduction of impurities, complex methods, collapse of the shell COFs structure, etc., to achieve rich porosity, simple preparation process, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of monomer 4,4',4",4"'-(9,9'-spirobifluorene-2,2',7,7'-tetrasubstituted)tetraphenylamine:

[0038] 2,2',7,7'-tetrabromo-9,9'-spirobifluorene (1264mg, 2.0mmol), 4-aminophenylboronic acid pinacol ester (2191mg, 10.0mmol), tetrabutyl bromide Ammonium (TBAB) (345mg, 10wt%), catalyst tetrakistriphenylphosphinepalladium (Pd(PPh 3 ) 4 ) is placed in the reaction flask, and the device is sealed to remove oxygen; prepare 2M potassium carbonate aqueous solution, and toluene are respectively deoxidized by nitrogen bubbling, and 20 mL of potassium carbonate aqueous solution and 40 mL of toluene after bubbling deoxygenation are injected into the reaction flask; reflux reaction 72 Hour. After the reaction, the crude product was used as a stationary phase with 100-200 mesh basic alumina, and petroleum ether / ethyl acetate (volume ratio 1:4) was used as an eluent for column chromatography separation and purification to obtain off-white powder. Recrystallization from n...

Embodiment 2

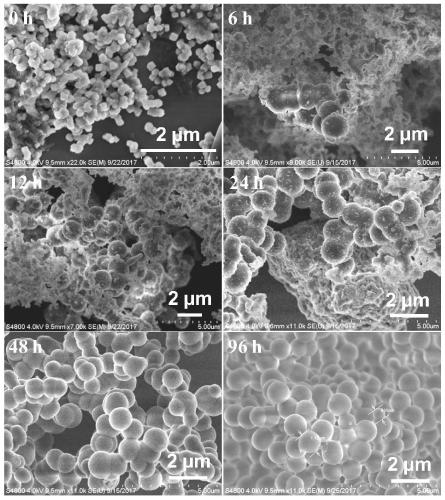

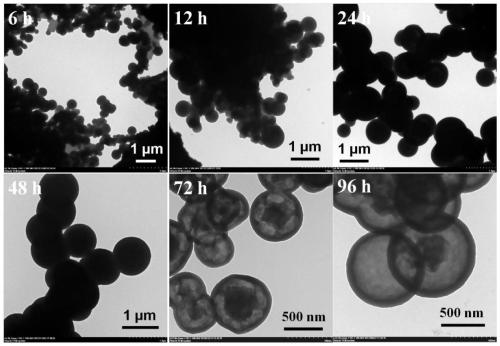

[0043] The preparation method is the same as that in Example 1, the only difference being that the reaction time of step (2) is changed, thereby resulting in a change in the morphology and structure. The reaction time is extended to 12 hours, the small particles of 180-240 nanometers in the product gradually decrease, and the large-size spheres with a diameter of 600-900 nanometers gradually increase, the surface of the spheres is rough, and the inner cavity is a solid structure (see figure 2 with image 3 ). The BET specific surface area of the product is 508m 2 g -1 , used as an electrode material for supercapacitors, the specific capacitance value is 64F / g (see Figure 8 ).

Embodiment 3

[0045] The preparation method is the same as that in Example 1, the only difference being that the reaction time of step (2) is changed, thereby resulting in a change in the morphology and structure. The reaction time is extended to 24 hours, the small particles of 200-500 nanometers in the product are further reduced, and the large-size spheres with a diameter of 600-900 nanometers are further increased, the surface of the spheres is rough, and the inner cavity is a solid structure (see image 3 with Figure 4 ). The product has a specific surface area of 550m 2 g -1 , used as an electrode material for a supercapacitor with a specific capacitance of 86F / g (see Figure 8 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com