Low-temperature resistant cellulose penicillium and application thereof

A Penicillium, cellulase technology, applied in the application, enzyme, hydrolase and other directions, to achieve the effects of high β-glucosidase activity, good environmental and economic benefits, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The separation and identification of embodiment 1 Penicillium NLS-2

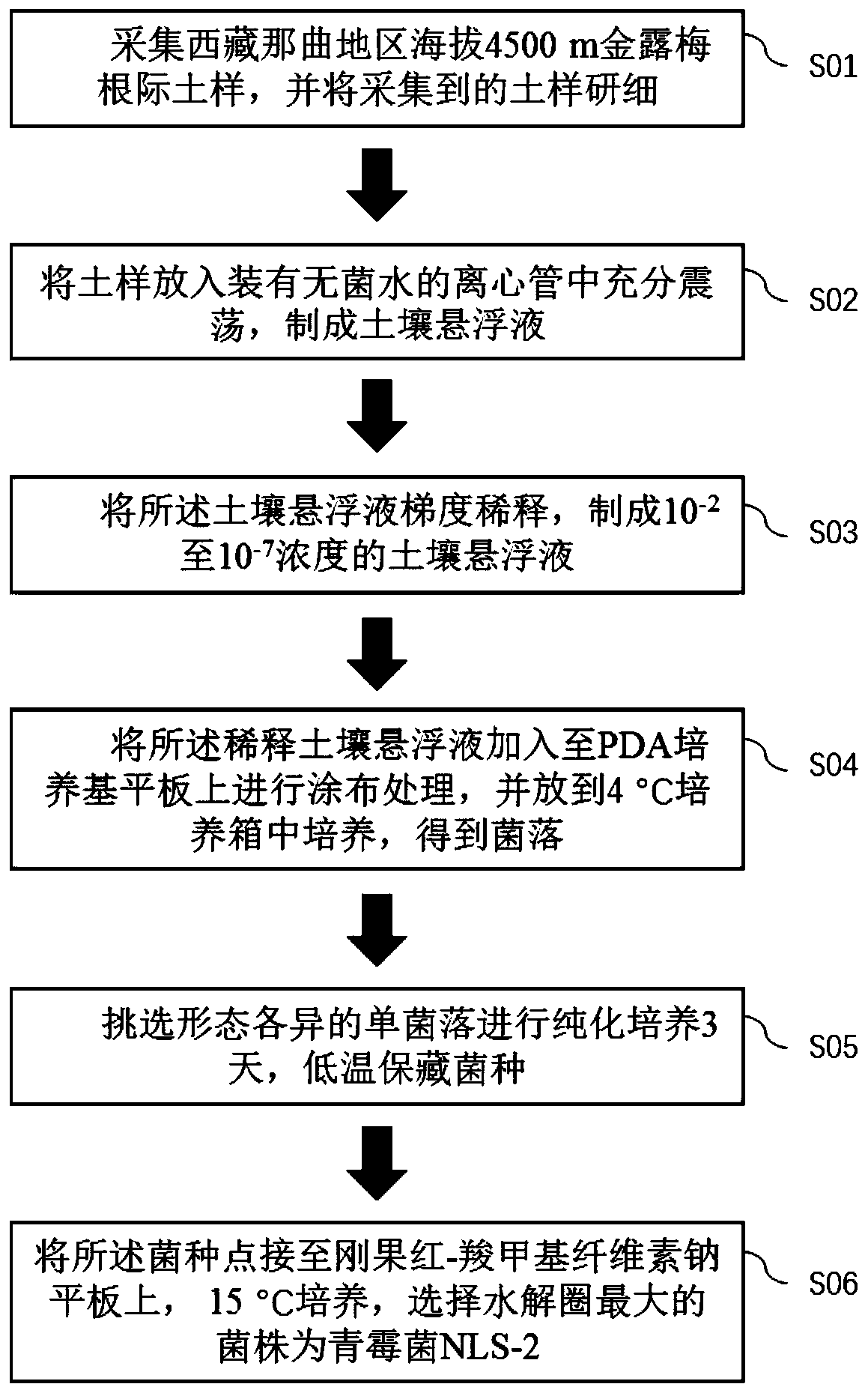

[0037] Please refer to figure 1 , figure 1 A flow chart for the preparation of the low-temperature resistant Penicillium cellulolyticum NLS-2 provided by the embodiment of the present invention is shown. The preparation steps of the low-temperature-resistant Penicillium cellulolyticum NLS-2 provided by the embodiments of the present invention are:

[0038] Collect soil samples from the rhizosphere of Prunus japonica at an altitude of 4500m in the Nagqu region of Tibet; put the collected soil samples into a centrifuge tube filled with sterile water and shake them fully to make a soil suspension; dilute the soil suspension gradient to make 10 -2 to 10 -7 concentration of soil suspension; add the diluted soil suspension to the PDA medium plate for coating treatment, and put it in a 4°C incubator for cultivation to obtain colonies; select single colonies with different shapes for purification, and cult...

Embodiment 2

[0048] Determination of cellulose degrading ability under the low temperature of embodiment 2 Penicillium strain NLS-2

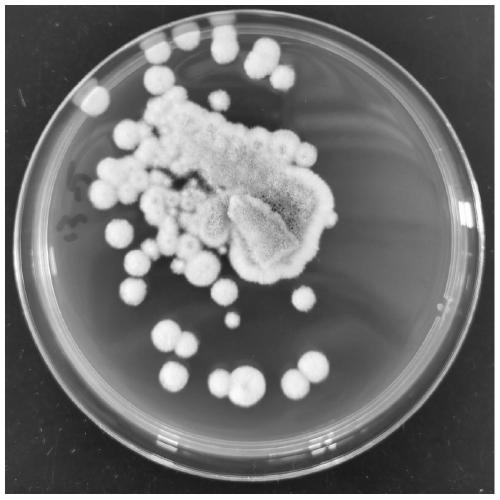

[0049] The embodiment of the present invention provides a schematic diagram of the hydrolysis effect of the low-temperature-resistant Penicillium cellulolyticum strain NLS-2 on a Congo red sodium carboxymethylcellulose plate, see Image 6 . from Image 6 It can be seen that at 15°C, the Congo red carmellose sodium plate inoculated with Penicillium strain NLS-2 had obvious hydrolysis circles after 5 days, and the diameter of the hydrolysis circles was above 17.4 mm, which was caused by the appearance of hydrolysis circles. It can be shown that the Penicillium strain NLS-2 provided in the examples of the present invention has a strong potential to degrade cellulose under low temperature conditions.

Embodiment 3

[0050] Example 3 Determination of Cellulase Production Ability of Penicillium Strain NLS-2 at Low Temperature

[0051] The embodiment of the present invention has carried out cellulase-producing ability assay to Penicillium bacterial strain NLS-2, and this assay includes the following contents:

[0052] 1. Preparation of crude enzyme solution

[0053] The bacterial strain NLS-2 provided by Example 1 of the present invention was inoculated into PDA liquid medium, cultivated at 15°C, 160r / min for 24h, and then inoculated with 2% inoculum in the enzyme-producing medium, at 15°C, 160r / min / min for 7 days. During this period, the enzyme activity was measured every 24 hours, and the fermentation broth was taken at 6000r / min, 4°C, centrifuged for 10min, and repeated three times at each time, and the supernatant was the crude enzyme solution.

[0054] The composition of described enzyme production medium is: CMC-Na 15.0g / L, yeast powder 5.0g / L, KH 2 PO 4 2.0g / L, pH7.0, sterilized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com