Preparation method of wild antheraea pernyi silk fibroin/aloe gel composite dressing

A technology of tussah silk fibroin and aloe vera gel, which is applied in the field of preparation of tussah silk fibroin/aloe vera gel composite dressing, can solve the problem that the speed and effectiveness of collagen wound repair are not as fast as aloe vera gel, and wound ulceration is not very effective. Composite scaffolds have the effect of enhancing cell adhesion and growth, promoting cell adhesion, and repairing wounds due to the high cost of composite scaffolds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

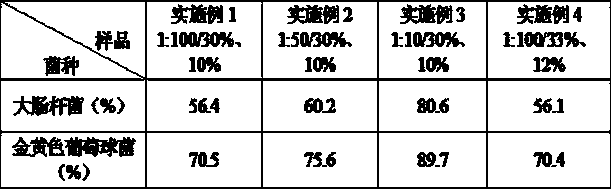

Embodiment 1

[0027] With 0.5~1% sodium carbonate (Na 2 CO 3 ) aqueous solution to degumming tussah silk, and then dissolve it with 5~10% lithium thiocyanate (LiSCN) aqueous solution, and after centrifugation, suction filtration, and dialysis, the regenerated tussah fibroin protein aqueous solution is obtained, and the obtained regenerated tussah silk fibroin The protein aqueous solution was concentrated until the mass percentage of tussah silk fibroin protein was 5-20%, which was recorded as solution A.

[0028] The aloe gel is crushed with a pulverizer, and the aloe gel powder is prepared by freeze-drying method. The aloe gel powder is dissolved in water to prepare a 1-10% aloe gel aqueous solution. The freezing temperature of the freeze-drying method is -80 ~ -20°C, the freezing time is 48 h.

[0029] Take solution A with 20% tussah fibroin protein mass percentage and 2% aloe vera gel aqueous solution for blending and stirring, and control the mass ratio of aloe vera gel and tussah fib...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is: embodiment 2 controls the mass ratio of aloe vera gel and tussah silk protein to be 1:50, and other operations are the same as embodiment 1, as follows:

[0035] With 0.5~1% sodium carbonate (Na 2 CO 3 ) aqueous solution to degumming tussah silk, and then dissolve it with 5~10% lithium thiocyanate (LiSCN) aqueous solution, and after centrifugation, suction filtration, and dialysis, the regenerated tussah silk fibroin protein aqueous solution is obtained, and the obtained regenerated tussah silk The protein aqueous solution is concentrated until the mass percentage of tussah silk fibroin protein is 5-20%, which is recorded as solution A.

[0036] The aloe gel is crushed with a pulverizer, and the aloe gel powder is prepared by freeze-drying method. The aloe gel powder is dissolved in water to prepare a 1-10% aloe gel aqueous solution. The freezing temperature of the freeze-drying method is -80 ~ -20°C, the freezi...

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 and embodiment 2 is: embodiment 3 controls the mass ratio of aloe vera gel and tussah silk protein to be 1:10, and other operations are the same as embodiments 1 and 2, as follows:

[0043] With 0.5~1% sodium carbonate (Na 2 CO 3 ) aqueous solution to degumming tussah silk, and then dissolve it with 5~10% lithium thiocyanate (LiSCN) aqueous solution, and after centrifugation, suction filtration, and dialysis, the regenerated tussah silk fibroin protein aqueous solution is obtained, and the obtained regenerated tussah silk The protein aqueous solution is concentrated until the mass percentage of tussah silk fibroin protein is 5-20%, which is recorded as solution A.

[0044] The aloe gel is crushed with a pulverizer, and the aloe gel powder is prepared by freeze-drying method. The aloe gel powder is dissolved in water to prepare a 1-10% aloe gel aqueous solution. The freezing temperature of the freeze-drying method is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com