Preparing method of tetraphenylphosphonium phenolate

A technology of tetraphenylphenol and tetraphenylphosphine bromide, which is applied in the field of preparation of tetraphenylphenol phosphonium salt, can solve the problems of isopropanol, large amount of phenol, and difficulty in stratification, so as to improve reaction efficiency and Yield, reduction of technological process, and reduction of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

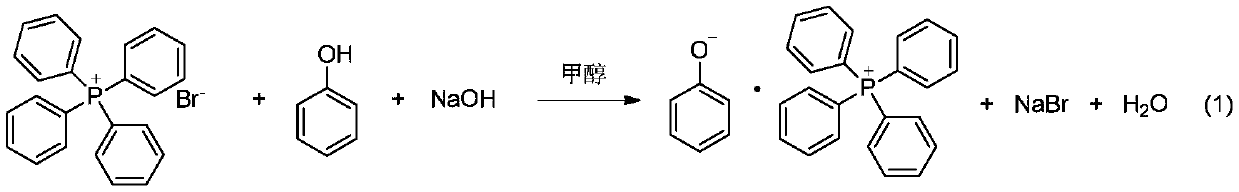

Method used

Image

Examples

Embodiment 1

[0029] Add 28.2g of phenol, 69.5g of methanol, 36g of tetraphenylphosphine bromide, and 84g of pure water, and start stirring until all of them are dissolved, then add 8.7g of sodium hydroxide (50% aqueous solution) dropwise at a temperature of 20-25°C, After the dropwise addition, when the temperature is stable, raise the temperature to 45°C and stir for 80 minutes, cool to 20-22°C, pour out and filter with suction to obtain 74.5g of wet product and 140.5g of mother liquor.

[0030] The wet product was soaked and washed twice with 59.4g and 71g of pure water to obtain 58.3g of wet product and 30.9g of dry product (83.2% yield);

[0031] The mother liquor was supplemented with 13g of methanol, 36.0g of tetraphenylphosphine bromide, and 24.2g of phenol. After stirring and dissolving, 7.6g of sodium hydroxide (50% aqueous solution) was added dropwise at 20-25°C, and stirred at 45°C for 90min to obtain the second Batch product 36.6g;

[0032] The mother liquor was supplemented w...

Embodiment 2

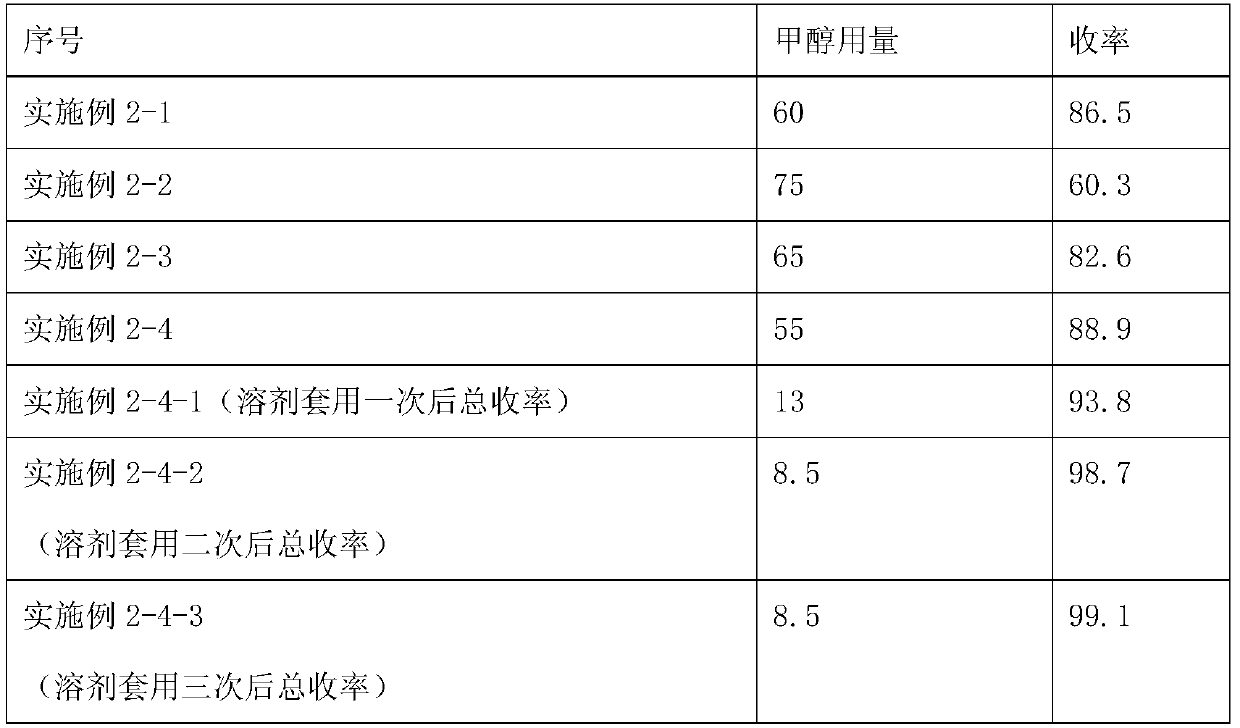

[0035] The preparation method is the same as in Example 1, except that the amount of methanol is adjusted and its influence on the reaction is tested, as shown in Table 1.

[0036] Table 1

[0037]

[0038] As shown in table 1: the amount of methanol has a greater impact on the reaction, and the increase of methanol will reduce the yield of a single batch of products, but the residue can be applied mechanically in the mother liquor; the total yield after solvent recycling three times can reach 99.1%, Tetraphenylphosphine bromide can basically achieve quantitative conversion after four reactions.

Embodiment 3

[0040] The preparation method is the same as that of Example 1, the difference is that the reaction temperature and the recovery time are adjusted, and their influence on the reaction is tested, as shown in Table 2.

[0041] Table 2

[0042] serial number temperature reflex Response time / minute yield Example 3-1 20 70 81.6 Example 3-2 20 90 78.5 Example 3-3 22 90 79.4 Example 3-4 23 90 78.5 Example 3-5 25 90 79.5

[0043] As shown in Table 2, when the reaction temperature is controlled between 20-25°C, the yield deviation is small, and according to the test results, the reaction can be completed within 1h20min; when the temperature is ≥45°C, the color of the product will deepen;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com