Microenvironment construction method for three dimensional culture of cells and application

A technology of three-dimensional culture and construction method, which is applied to the construction of three-dimensional cell culture microenvironment, and in the application field of organ chips, which can solve the problems of complicated 3D forming methods, long time for removing DNA, and large damage to the active components of the extracellular matrix. Achieve the effects of shortening the preparation time, low price, and retaining active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

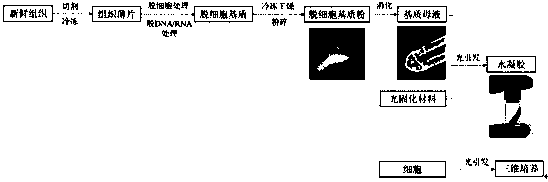

Method used

Image

Examples

Embodiment 1

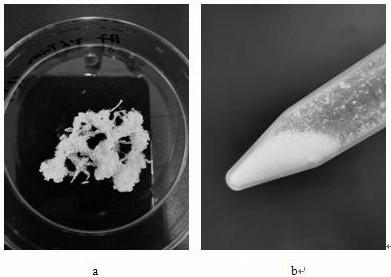

[0059] (1) Select fresh pig heart, wash to remove fat, blood and other appendages, freeze at -20°C, cut into thin slices of about 500 μm with a scalpel on ice, stir and wash the thin slices with 0.01M PBS buffer solution for 15 minutes, repeat 3 times; after draining the flakes, stir them with 0.1% trypsin for 2 hours, treat them with 3% Triton X-100 for 2 hours, treat them with 1% SDS for 4 hours, and wash them with 0.01M PBS buffer solution for 15 minutes every 2 hours. 0.01M PBS mixed solution of 2000Ku ribonuclease and 2000Ku deoxyribonuclease was stirred for 1 hour, after the decellularization treatment was completed, stirred and washed with deionized water, replaced with deionized water every 15 minutes, repeated 3 times, and the conductivity was detected to be less than 10μs / cm; the matrix was drained, freeze-dried, and pulverized into a powder with a grinder. Take the powder and prepare 10mg / mL matrix mother solution with 0.1M hydrochloric acid solution containing 5mg...

Embodiment 2

[0061] (1) Select fresh pig lungs, wash and remove fat, blood and other appendages, freeze at -20°C, cut into slices of about 500 μm with a scalpel on ice, stir and wash the slices with 0.01M PBS buffer solution for 15 minutes, repeat 3 times; after draining the flakes, they were treated with 1% CHAPS (3-[3-(cholamidopropyl)dimethylamino]propanesulfonic acid inner salt) for 2h, 2% sodium deoxycholate for 4h, each treatment was 2h, Stir and wash with 0.01M PBS buffer solution for 15min, stir and treat with 0.01M PBS mixed solution containing 2000Ku ribonuclease and 2000Ku deoxyribonuclease for 1h, after the decellularization treatment is completed, stir and wash with deionized water, replace it every 15min Ionized water, repeated 3 times, no surfactant in the washing was detected by high performance liquid chromatography; the matrix was drained of water, freeze-dried, and pulverized into powder with a grinder. Take the powder and prepare 10mg / mL matrix mother solution with 0.01...

Embodiment 3

[0063] (1) Select fresh pig lungs, wash and remove fat, blood and other appendages, freeze at -20°C, cut into slices of about 500 μm with a scalpel on ice, stir and wash the slices with 0.01M PBS buffer solution for 15 minutes, repeat 3 times; drain the flakes and treat them with 1% SDS for 4 hours, and wash them with 0.01M PBS buffer solution for 15 minutes every 2 hours, and then treat them with 0.01M PBS mixed solution containing 2000Ku ribonuclease and 2000Ku deoxyribonuclease 1h, the deionized water treatment is over, stir and wash with deionized water, replace the deionized water every 15min, repeat 3 times, and detect that the conductivity is less than 10μs / cm; drain the matrix, freeze-dry it, and pulverize it with a grinder powder. Take the powder and prepare 10mg / mL matrix mother solution with 0.01M hydrochloric acid solution containing 5mg / mL pepsin, shake at room temperature for 48h, centrifuge at 10000rpm / min, and take the supernatant; prepare 50mg / mL methacrylic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com