Full-strength cationic grafted natural polymer sludge conditioner and preparation method thereof

A technology of natural macromolecules and strong cations, applied in the field of full-strength cationic grafted natural macromolecular sludge conditioner and its preparation, can solve the problems of pH sensitivity, poor solubility and low molecular weight of flocculation effect, and achieve dehydration effect Good, low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

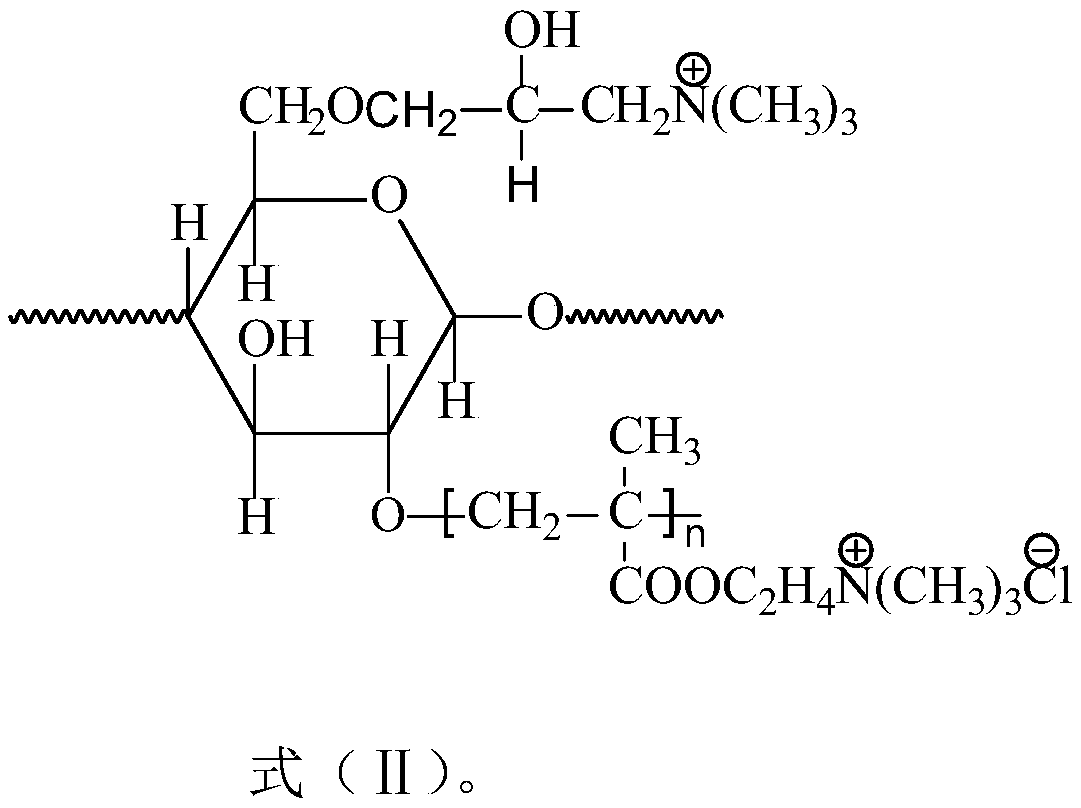

[0033] A kind of preparation method of described full-strength cationic graft natural polymer sludge conditioner of the present invention, it can be prepared by the reaction formula of formula (Ⅲ), comprises the steps:

[0034]

[0035] (1) Dispersing starch (weight-average molecular weight is 150,000) in 10% sodium hydroxide solution (solvent is a mixed solvent of water and isopropanol, wherein the mass ratio of water to isopropanol is 1:1) ), alkalized for 1 hour; after that, adding CTA mass percentage concentration is 50% isopropanol solution (wherein CTA and starch mass ratio are 1:1), reacted 4 hours at 50 ℃, after the completion of the reaction, ethanol was used as precipitation agent, precipitated and separated to obtain the main chain cationized starch.

[0036] (2) dissolving the main chain cationized starch in water, and configuring it into a solution with a main chain cationized starch mass percentage concentration of 1%. After the solution is uniform, add potass...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is: the preparation method of a kind of described full-strength cationic graft natural polymer sludge conditioner of the present invention, comprises the steps:

[0040] In step (1), the cellulose (weight-average molecular weight is 500,000) is dispersed in the mass percentage concentration and is 1% potassium hydroxide solution (solvent is water and isopropanol mixed solvent, wherein the quality of water and isopropanol Ratio is 1:3), alkalized for 1.5 hours; after that, adding CTA mass percent concentration is 30% isopropanol solution (wherein CTA and cellulose mass ratio are 2:1), reacted at 60 ℃ for 5 hours, the reaction After completion, ethanol is used as a precipitating agent for precipitation and separation to obtain main chain cationized cellulose.

[0041] In step (2), the main chain cationized cellulose is dissolved in water, configured into a solution with a main chain cationized cellulose mass percentage ...

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is: the preparation method of a kind of described full-strength cationic graft natural polymer sludge conditioner of the present invention, comprises the steps:

[0045] In step (1), starch (weight-average molecular weight is 50,000) is dispersed in the mass percent concentration and is 15% sodium hydroxide solution (solvent is water and isopropanol mixed solvent, wherein the mass ratio of water and isopropanol 1:0.2), alkalized for 2 hours; after that, add CTA mass percent concentration and be 20% isopropanol solution (wherein CTA and starch mass ratio are 3:1), react at 30 ℃ for 1 hour, after the reaction is completed Using ethanol as a precipitant, precipitation and separation, the main chain cationized starch is obtained.

[0046] In step (2), the main chain cationized starch is dissolved in water, configured into a solution with a main chain cationized starch mass percentage concentration of 1.5%, and after the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com