Method for decomposing ternary alloys to prepare silicon or germanium nanometer materials

A ternary alloy, nanomaterial technology, applied in nanotechnology, chemical instruments and methods, silicon compounds, etc., can solve problems such as limiting the practical application ability of products, difficult to remove, etc., to avoid particle inhomogeneity, low cost, and production. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

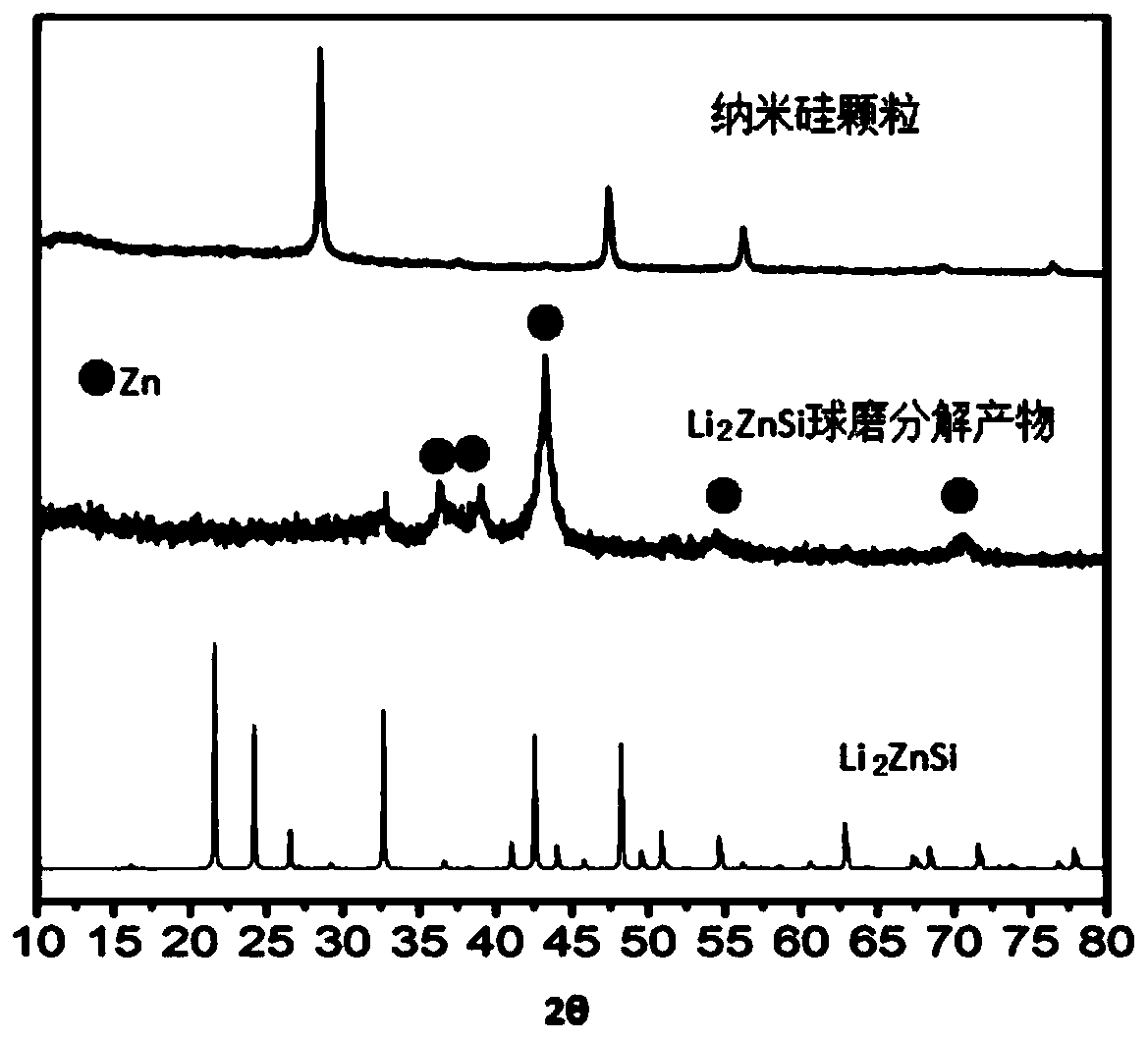

[0055] Mechanical ball milling to decompose Li 2 ZnSi ternary alloy compound prepares the method for nano-silicon material, comprises steps:

[0056] (1) In an argon atmosphere glove box, the elemental Li, Zn, and Si were mixed and sealed in a metal tantalum container at a molar ratio of 2:1:1, and the metal tantalum container was placed in a vacuum environment and heated at 190°C / h The heating rate was raised to 600°C and kept for 3 hours, then cooled with the furnace, the metal tantalum container was opened in an argon atmosphere glove box, and the material obtained by the solid phase reaction was ground until it had no metallic luster. Then the ground material was sealed into a metal tantalum container for the second time, and the metal tantalum was placed in a vacuum environment, and the temperature was raised to 770° C. at a heating rate of 210° C. / h for 4 hours. Open the metal tantalum container in an argon atmosphere glove box, and grind the Li-Zn-Si ternary alloy comp...

Embodiment 2

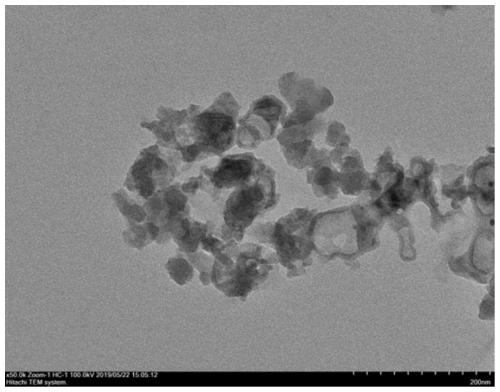

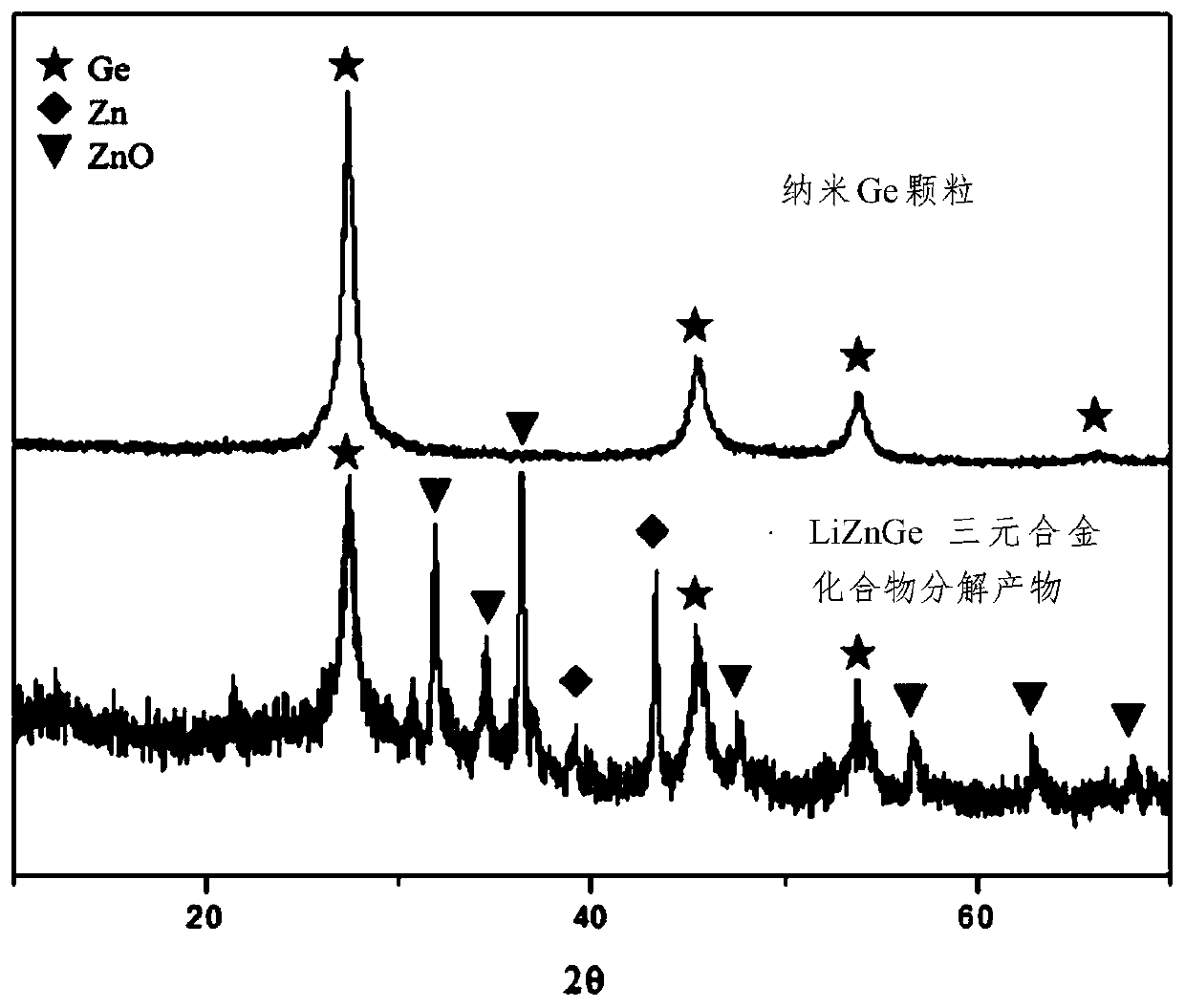

[0061] The method for slowly oxidizing and decomposing LiZnGe ternary alloy compound to prepare nano-germanium material, comprising steps:

[0062] (1) In an argon atmosphere glove box, mix and seal elemental Li, Zn, and Ge in a molar ratio of 1:1:1 into a metal tantalum container, place the metal tantalum container in a vacuum environment, and heat at 80°C / h The heating rate was raised to 400°C for 12 hours, and then the temperature was raised to 850°C for 48 hours at a heating rate of 80°C / h. The metal tantalum container was opened in an argon atmosphere glove box, and the Li-Zn-Ge ternary alloy compound obtained by the solid-state reaction was ground until there was no metallic luster to obtain the LiZnGe ternary alloy compound.

[0063] (2) In an argon atmosphere glove box, put the LiZnGe ternary alloy compound powder into a glass container, and place the glass container in the air for 30 days until it is completely decomposed. Take 1g of powder and add it to 500ml of 1.2...

Embodiment 3

[0067] A method for preparing a nano-germanium material by decomposing a LiZnGe ternary alloy compound with a weak acid solution, comprising the steps of:

[0068] (1) LiZnGe ternary alloy compound was prepared as described in Example 2.

[0069] (2) Prepare an acidic buffer solution with pH=6 with glacial acetic acid, anhydrous sodium acetate and deionized water, the calculated molar ratio of glacial acetic acid and sodium acetate is 0.056:1; get 1g of LiZnGe ternary alloy compound powder and add 500ml of Acidic buffer solution and stirring magnets were put into a glass container with argon atmosphere; the glass container was immersed in a 30°C water bath, and the magnetic stirring was adjusted to produce vortex in the glass container. After 24 hours of uninterrupted stirring and reaction, the glass container was opened in the air. The solution in the glass container was filtered, the obtained precipitate was washed with deionized water, and vacuum-dried at 70° C. for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com