Fuel cell stainless steel bipolar plate preparation and surface modification method

A surface modification, fuel cell technology, used in fuel cells, fuel cell parts, pretreated surfaces, etc., can solve the problems of decreased membrane electrode performance, increased fuel cell internal resistance, high cost, and improved corrosion resistance. The effect of improving performance, corrosion resistance, and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

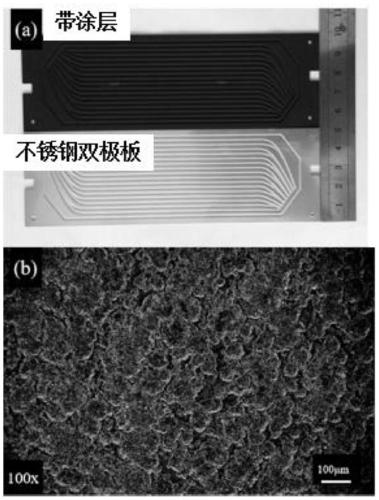

[0073] (1) Preparation of stainless steel bipolar plates by chemical etching

[0074] Wire-cut a 1.0mm stainless steel plate into a substrate with a size of 156mmⅹ50mm; take 270.3g of ferric chloride hexahydrate solid, add 630.7mL of deionized water, and configure FeCl with a mass fraction of 30% 3 Chemical etching solution, then add 13mL concentrated nitric acid and 25mL concentrated hydrochloric acid. After degreasing the stainless steel substrate in a 35% sodium hydroxide solution at 60°C for 30 minutes, wash it with water and dry it. A 30 μm thick photosensitive ink layer was rolled on the surface of the degreased stainless steel substrate, and dried at 85° C. for 1 hour. Put the film film with flow channel pattern close to the ink layer of the photosensitive substrate, and irradiate it under a UV lamp for 80s; develop the exposed photosensitive ink layer in a sodium carbonate solution with a mass fraction of 1% for 2min, and cure it at 180°C for 2h Afterwards, the devel...

Embodiment 2

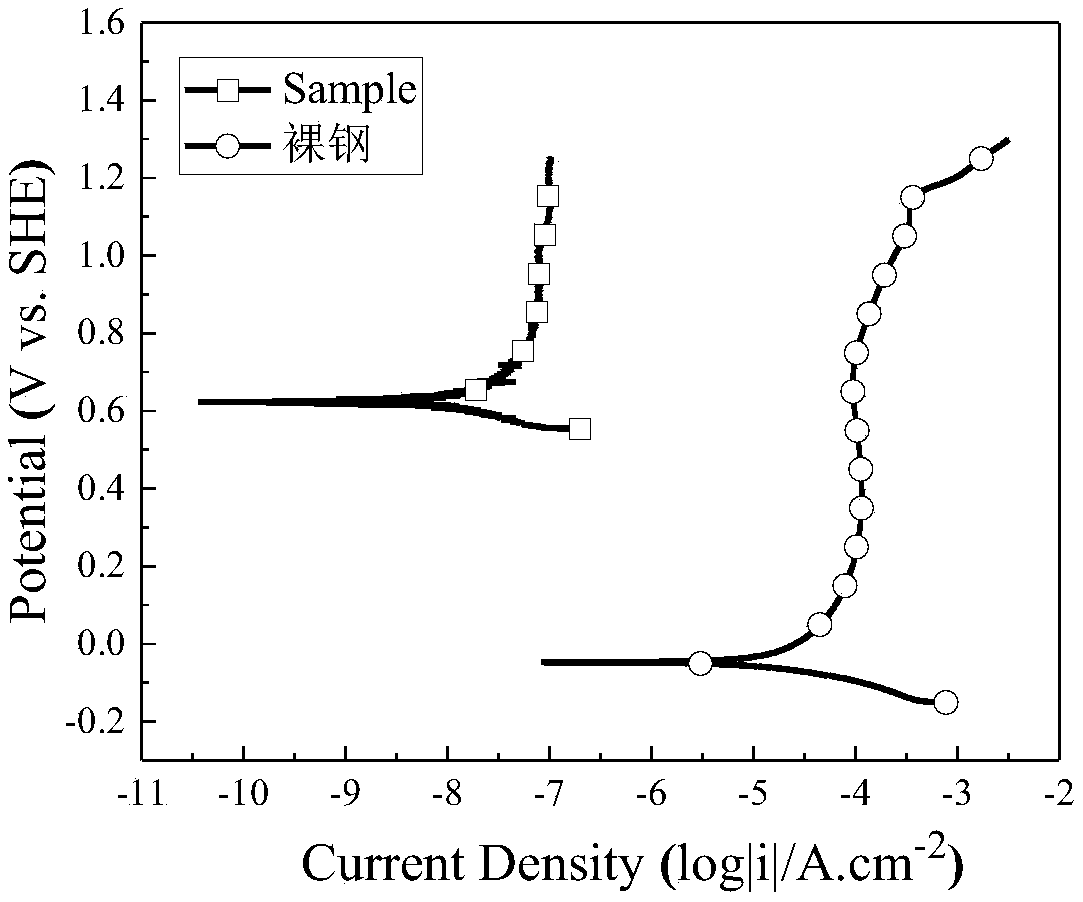

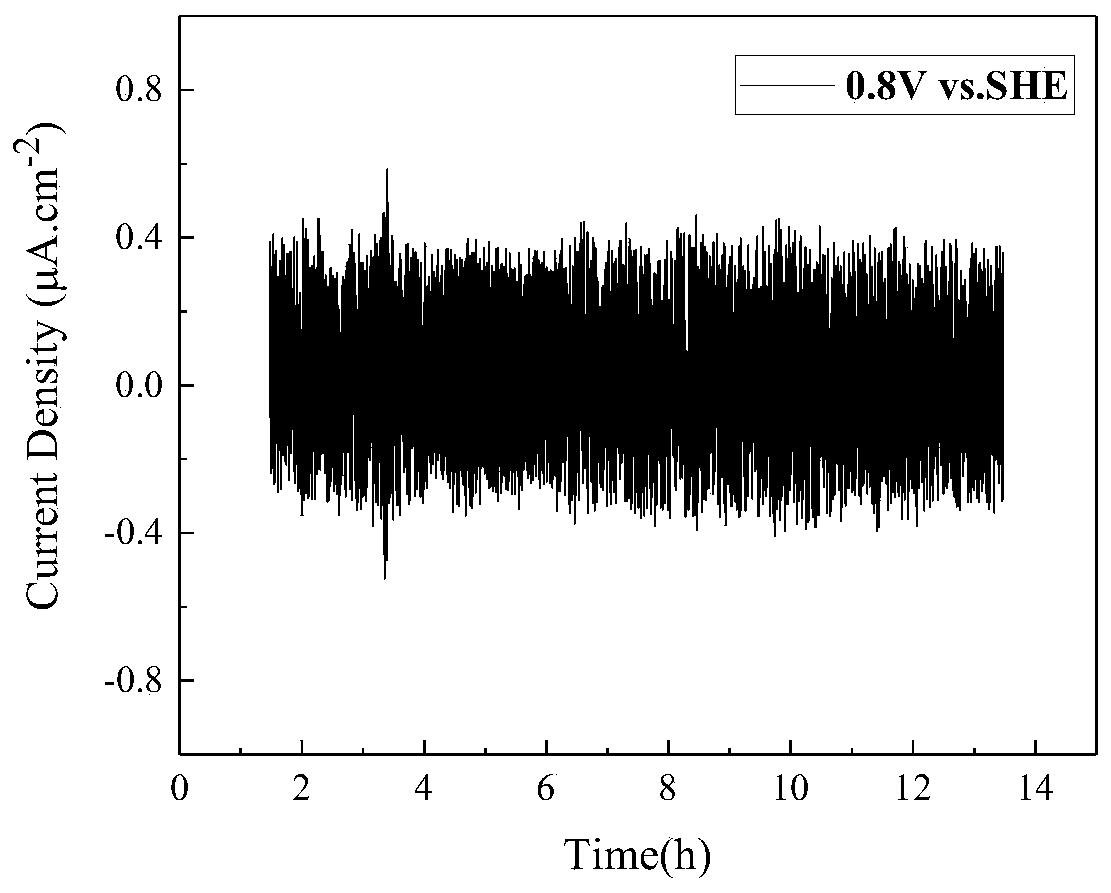

[0078] Nano-superconducting carbon / nano-graphite / PI / PF coating preparation

[0079] Take 20mL of nitrogen nitrogen dimethylacetamide (DMAC) and add it into two cylinders A and B in equal amounts, and add 0.1303g and 0.0.3958g of nano superconducting carbon into A and B respectively. Weigh 0.3958g of nano-graphite with a particle size of 30nm, add it to B, add a magnetic stirrer, adjust the rotation speed to 800r / min, and the time to 3.0h. Then take 1.1724g, 0.2638g of PF resin with a solid content of 80%, and then weigh 0.2638g of PI resin with a solid content of 70% and add them to B, adjust the rotation speed to 1000r / min, and the time to 3h. The obtained solid-to-liquid ratio is: 1:8, carbon content is 10% nanometer superconducting carbon / PF hybrid coating (S1), and conductive material contains nanometer superconducting carbon / nanographite / PF / PI (nano superconducting carbon:nanostone=1:1, PF:PI=1:1) mixed coating (S2). Then preheat the stainless steel bipolar plate to 220...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com