Catalyst carrier, supported catalyst and preparation method and application thereof

A supported catalyst and catalyst carrier technology, applied in catalyst activation/preparation, chemical instruments and methods, preparation of organic compounds, etc. effect, improving catalyst stability, reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Vector preparation:

[0048] (1) Weigh 3.0 g of glucose and 1.6 g of boric acid, dissolve them in deionized water, and stir at room temperature for 8 hours.

[0049] (2) Continue to stir the above solution in a 60°C oil bath to make it dry.

[0050] (3) Transfer the dried sample to a tube furnace, heat up to 300°C at 5°C / min under an argon atmosphere, and bake at an argon flow rate of 100mL / min for 1h, then raise the temperature at 5°C / min under an argon atmosphere To 800°C, the argon flow rate is 100mL / min, roast for 2h, and then lower the temperature.

[0051] (4) Grinding the calcined product into fine powder in a mortar, washing with hot water three times in a sand core funnel, washing once with absolute ethanol, and drying in an oven to obtain a carrier.

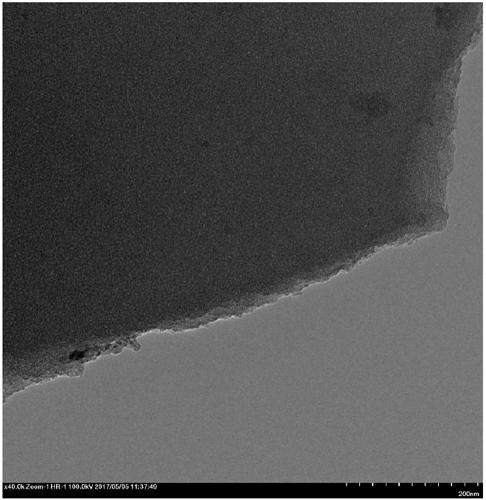

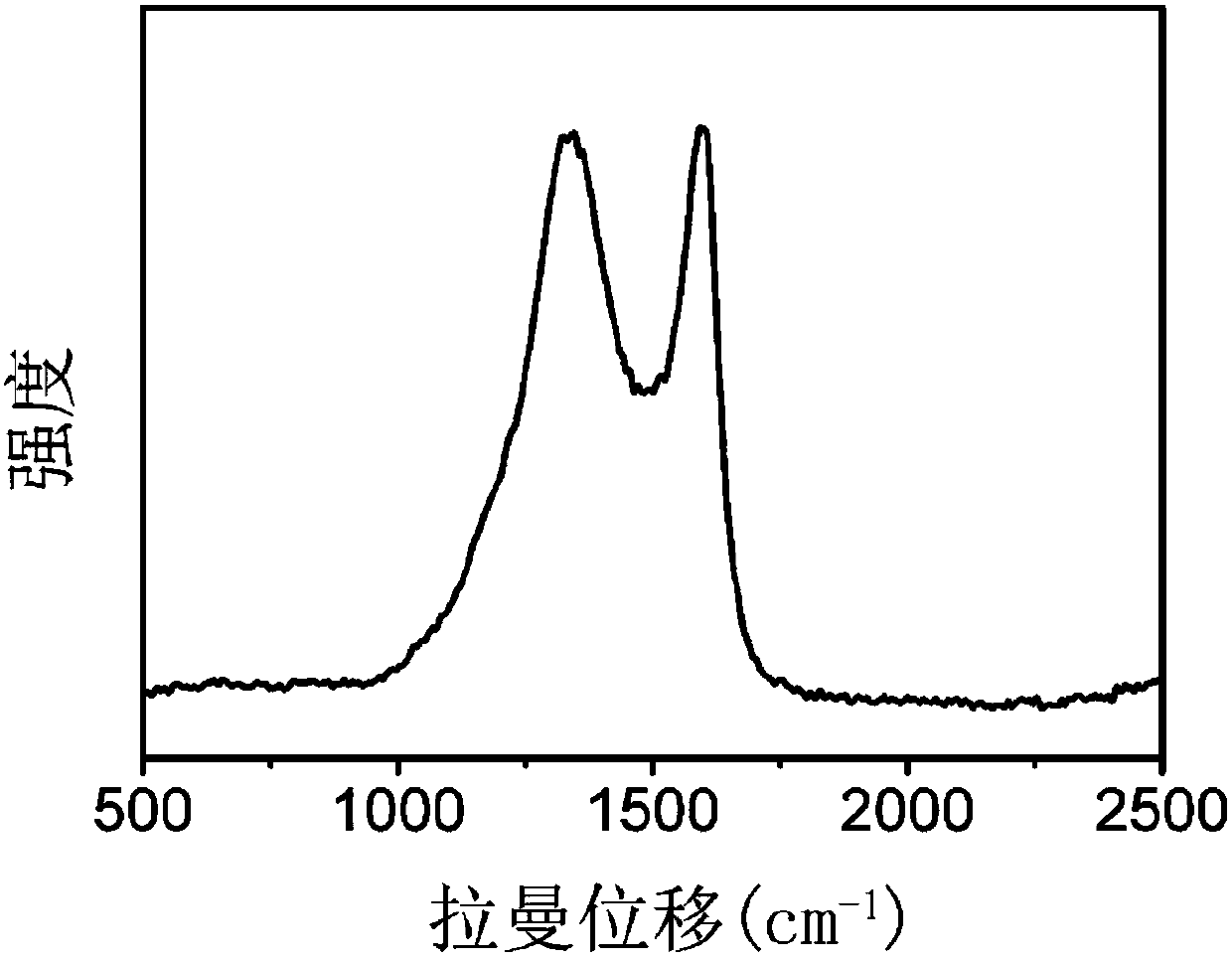

[0052] TEM characterization to obtain the morphology of the catalyst support, such as figure 1 , indicating that the carrier is composed of sheet-like structures. Raman results showed that the catalyst suppor...

Embodiment 2

[0059] Vector preparation:

[0060] (1) Weigh 3.0 g of glucose and 3.2 g of boric acid, dissolve them in deionized water, and stir at room temperature for 8 hours.

[0061] (2) Continue to stir the above solution in a 60°C oil bath to make it dry.

[0062] (3) Transfer the dried sample to a tube furnace, heat up to 300°C at 5°C / min under an argon atmosphere, and bake at an argon flow rate of 100mL / min for 1h, then raise the temperature at 5°C / min under an argon atmosphere To 900°C, the argon flow rate is 100mL / min, roast for 2h, and then lower the temperature.

[0063] (4) Grinding the calcined product into fine powder in a mortar, washing with hot water three times in a sand core funnel, washing once with absolute ethanol, and drying in an oven to obtain a carrier.

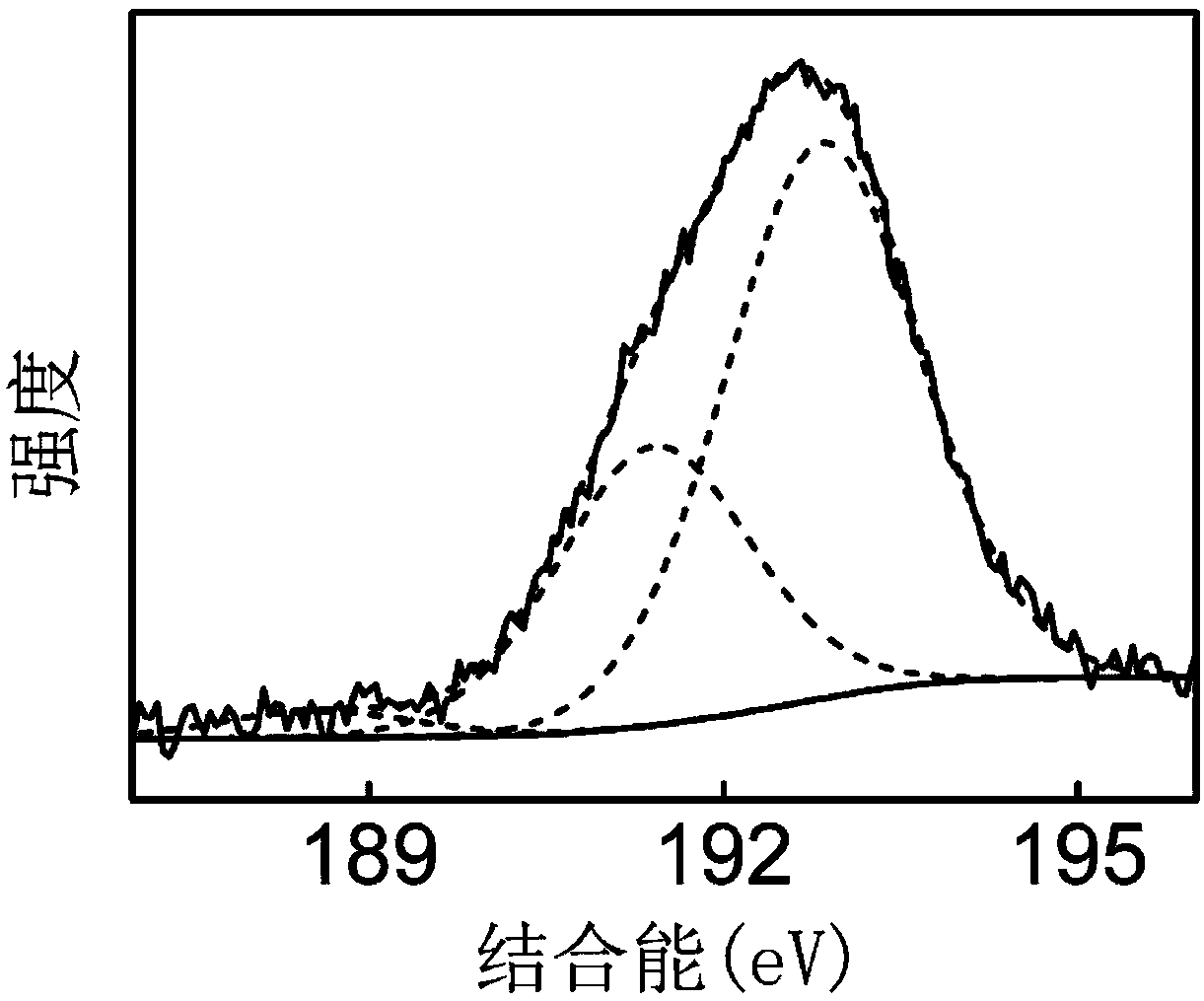

[0064] The obtained catalyst support is composed of flake-shaped amorphous carbon material modified with boron and oxygen elements, wherein the boron element is represented by BC 3 、BCO 2 and BC 2 The form o...

Embodiment 3

[0070] Vector preparation:

[0071] (1) Weigh 3.0 g of glucose and 3.2 g of boric acid, dissolve them in deionized water, and stir at room temperature for 8 hours.

[0072] (2) Continue to stir the above solution in a 60°C oil bath to make it dry.

[0073] (3) Transfer the dried sample to a tube furnace, heat up to 300°C at 5°C / min under an argon atmosphere, and bake at an argon flow rate of 100mL / min for 1h, then raise the temperature at 5°C / min under an argon atmosphere To 1000°C, the argon flow rate is 100mL / min, roast for 2h, and then lower the temperature.

[0074] (4) Grinding the calcined product into fine powder in a mortar, washing with hot water three times in a sand core funnel, washing once with absolute ethanol, and drying in an oven to obtain a carrier.

[0075] The obtained catalyst support is composed of flake-shaped amorphous carbon material modified with boron and oxygen elements, wherein the boron element is represented by BC 3 、BCO 2 and BC 2 The form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com