Gradient solder layer preparation and integrated brazing process based on laser fused deposition additive manufacturing technology

An additive manufacturing and laser melting technology, applied in the field of welding, to avoid joint cracking and deformation, improve efficiency, and improve service performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

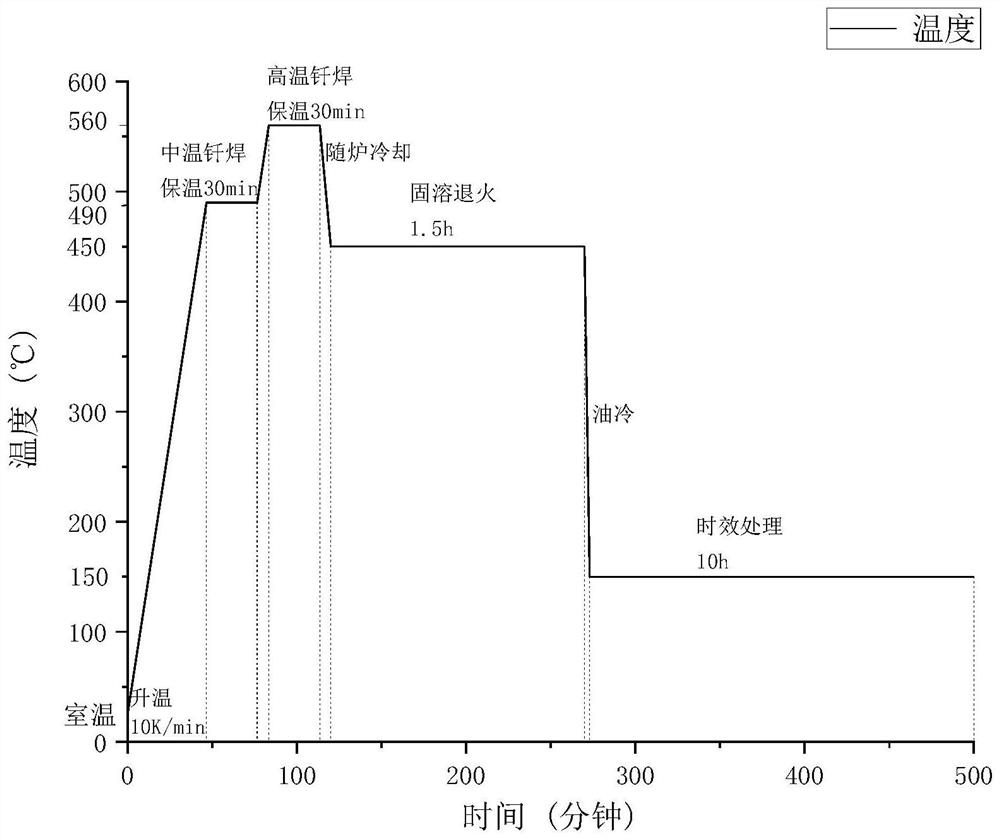

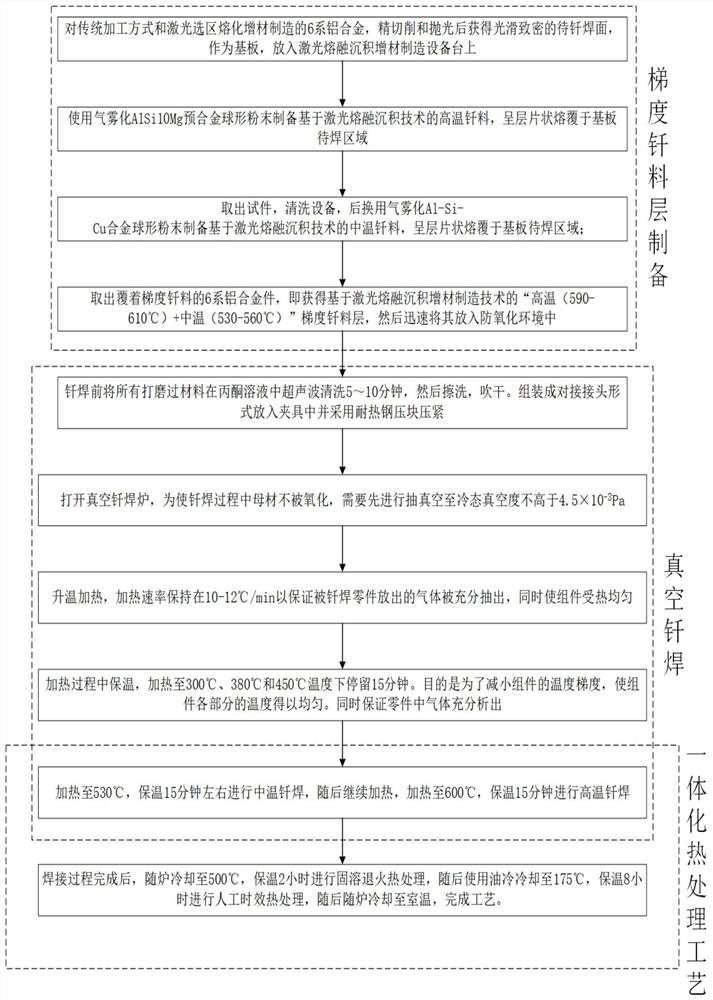

[0040] A preparation method based on a temperature gradient solder layer and an integrated process for vacuum brazing and heat treatment of 6-series aluminum alloys aimed at laser selective melting manufacturing technology, the specific steps are as follows:

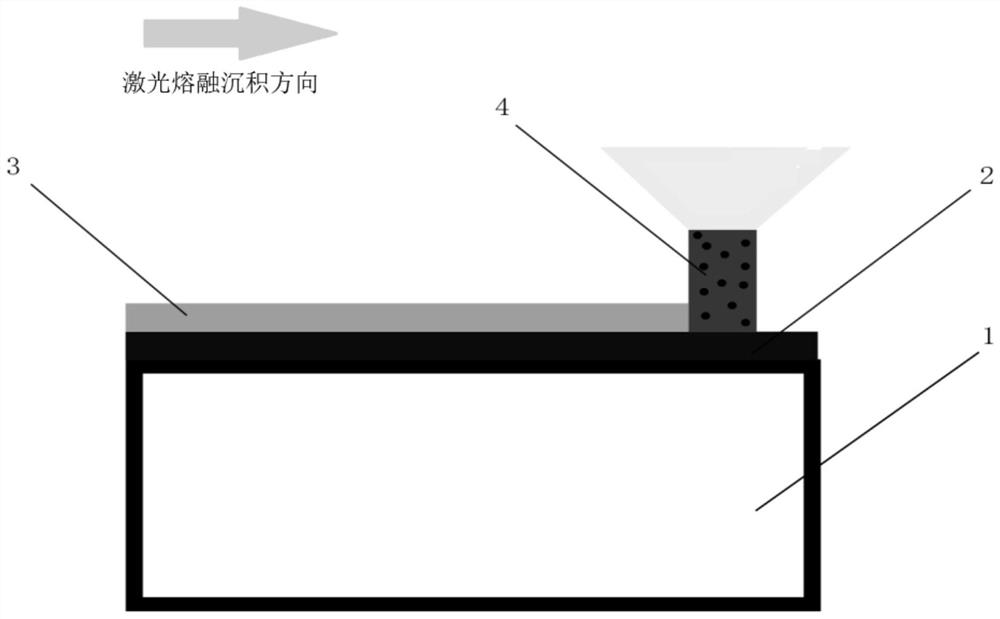

[0041] Step 1, the 6-series aluminum alloy manufactured by laser selective melting and additive manufacturing, after fine cutting and polishing, the surface to be brazed with a surface roughness of 6.3 is used as a substrate, and placed on the laser fusion deposition additive manufacturing equipment table;

[0042] Step 2, use the mass fraction of Si: 10.0%, Mg: 0.60%, Fe: 2.0%, Al: the balance of AlSi10Mg alloy melt gas atomization to obtain pre-alloyed powder with a particle size of 50 μm, under the protection of argon atmosphere, use laser Fused deposition additive manufacturing technology, fixed laser power fixed laser power 650W, scanning speed 6m min -1 , the scanning distance is 90 μm, the phase angle is 90°, the ...

Embodiment 2

[0050] A method for preparing a solder layer based on a temperature gradient and an integrated process for austenitic stainless steel vacuum brazing and heat treatment for laser selective melting manufacturing technology, the specific steps are as follows:

[0051] Step 1, the austenitic stainless steel manufactured by laser selective melting and additive manufacturing, after fine cutting and polishing, the surface to be brazed with a surface roughness of 6.3 is used as a substrate, and placed on the laser fusion deposition additive manufacturing equipment table;

[0052] Step 2, using the mass fraction of Cr: 11%, Fe: 4.2%, B: 2.8%, Si: 5%, C: 0.03%, Ni: the balance of B-Ni2 nickel-based alloy melt gas atomization to obtain Pre-alloyed powder with a particle size of 50 μm, under the protection of argon atmosphere, using laser fusion deposition additive manufacturing technology, the power parameters used are: laser power 1100W, scanning speed 10m min -1 , the scanning distance...

Embodiment 3

[0060] A preparation method based on a temperature gradient solder layer and a Ti-6Al-4V titanium alloy vacuum brazing and heat treatment integrated process for laser selective melting manufacturing technology, the specific steps are as follows:

[0061] Step 1: For the Ti-6Al-4V titanium alloy manufactured by laser selective melting and additive manufacturing, after fine cutting and polishing, the surface to be brazed with a surface roughness of 6.3 is achieved, as a substrate, and placed on the laser fusion deposition additive manufacturing equipment table ;

[0062] Step 2, use the pre-alloyed powder with a particle size of 50 μm obtained after gas atomization of the Ti-Cu-Ni alloy melt with a mass fraction of Ti: 65%, Cu: 12%, and Ni: the balance, and use a laser under the protection of an argon atmosphere to Fused deposition additive manufacturing technology, the power parameters used are: laser power 1000W, scanning speed 10m min -1 , the scanning distance is 90 μm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com