Resin grinding wheel for glass cutting and preparation method thereof

A resin grinding wheel and glass cutting technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of large chipping, cutting sparking grinding wheels, and low cutting efficiency, so as to reduce chipping edge size, reduce edge chipping size, and improve cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

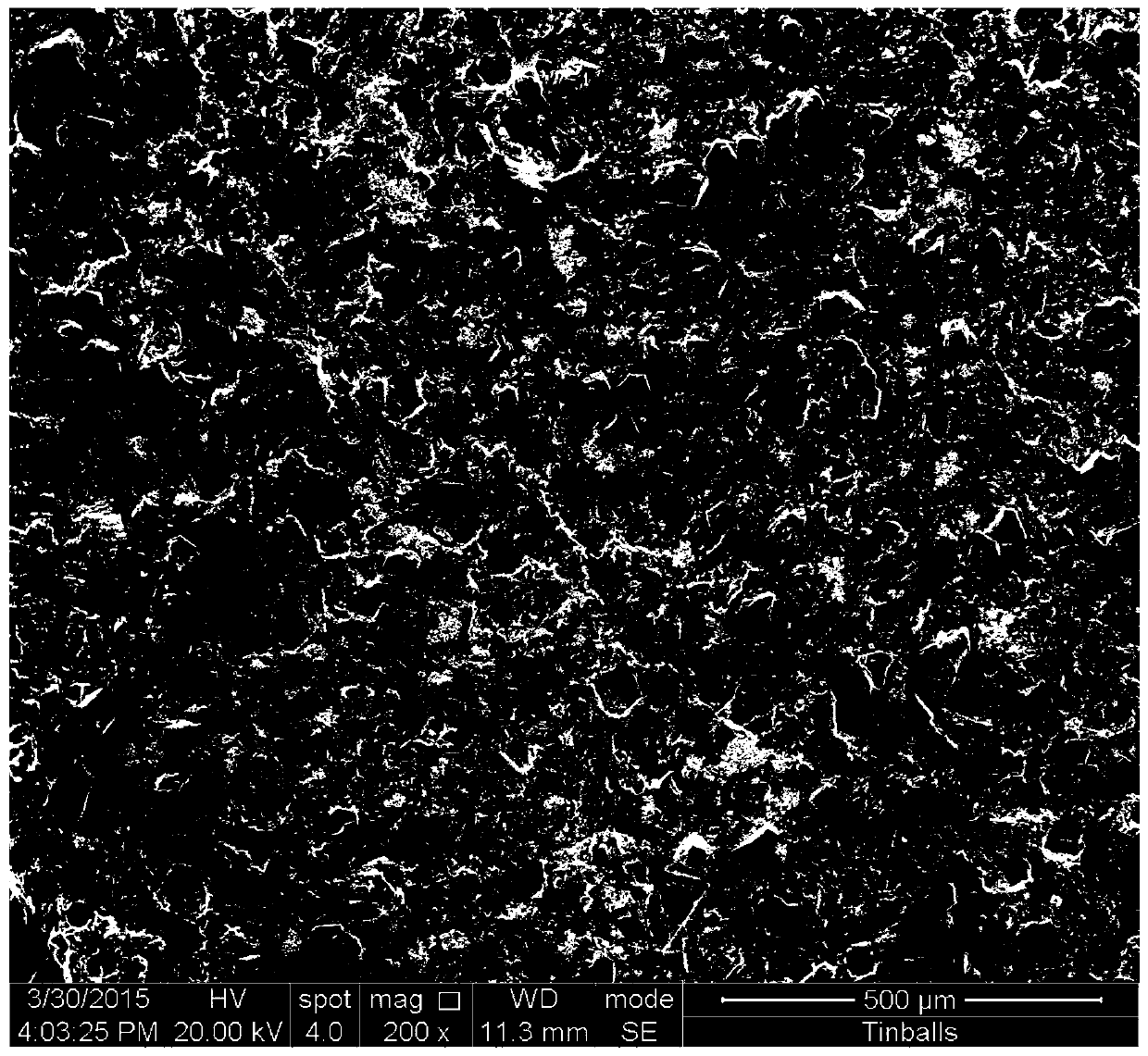

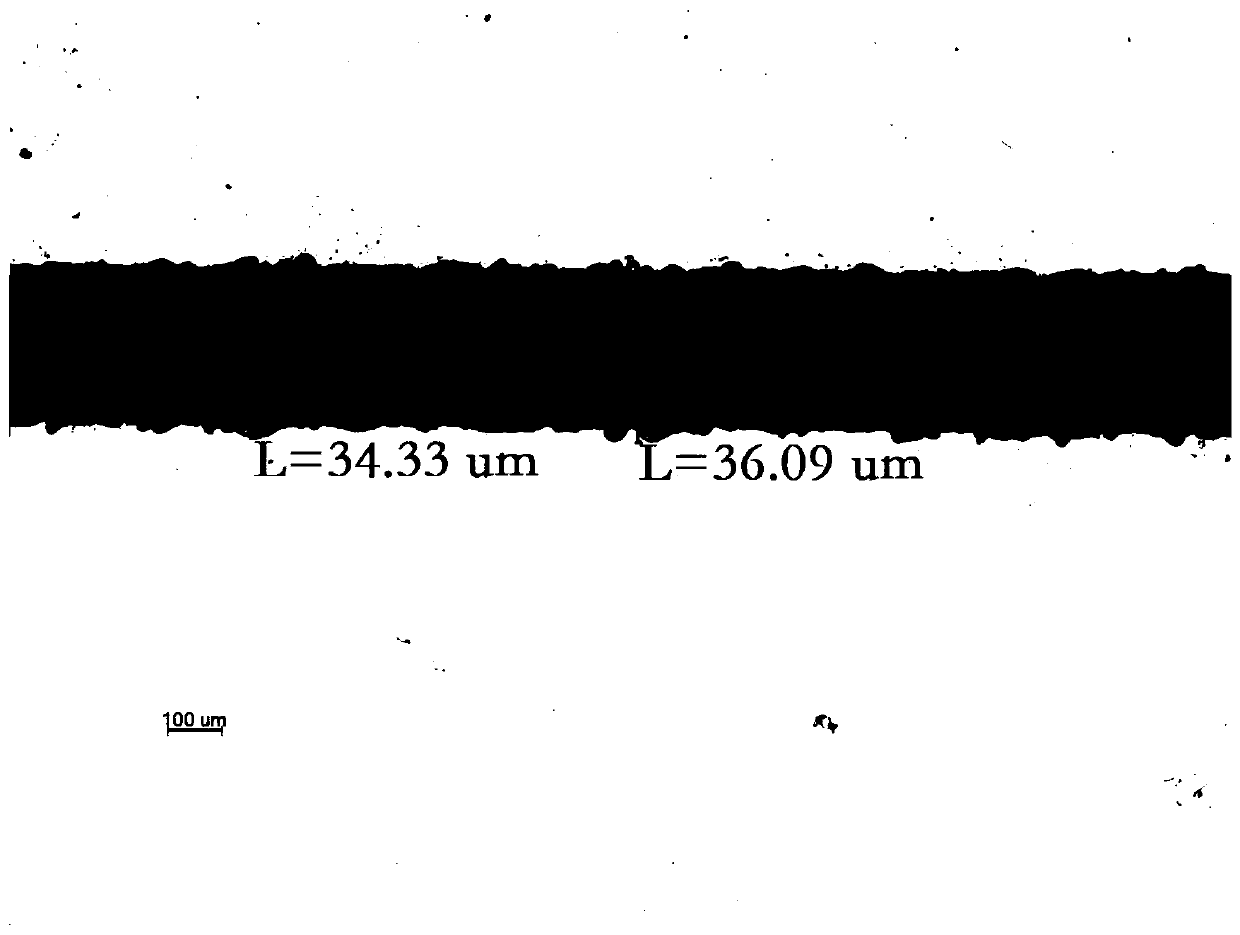

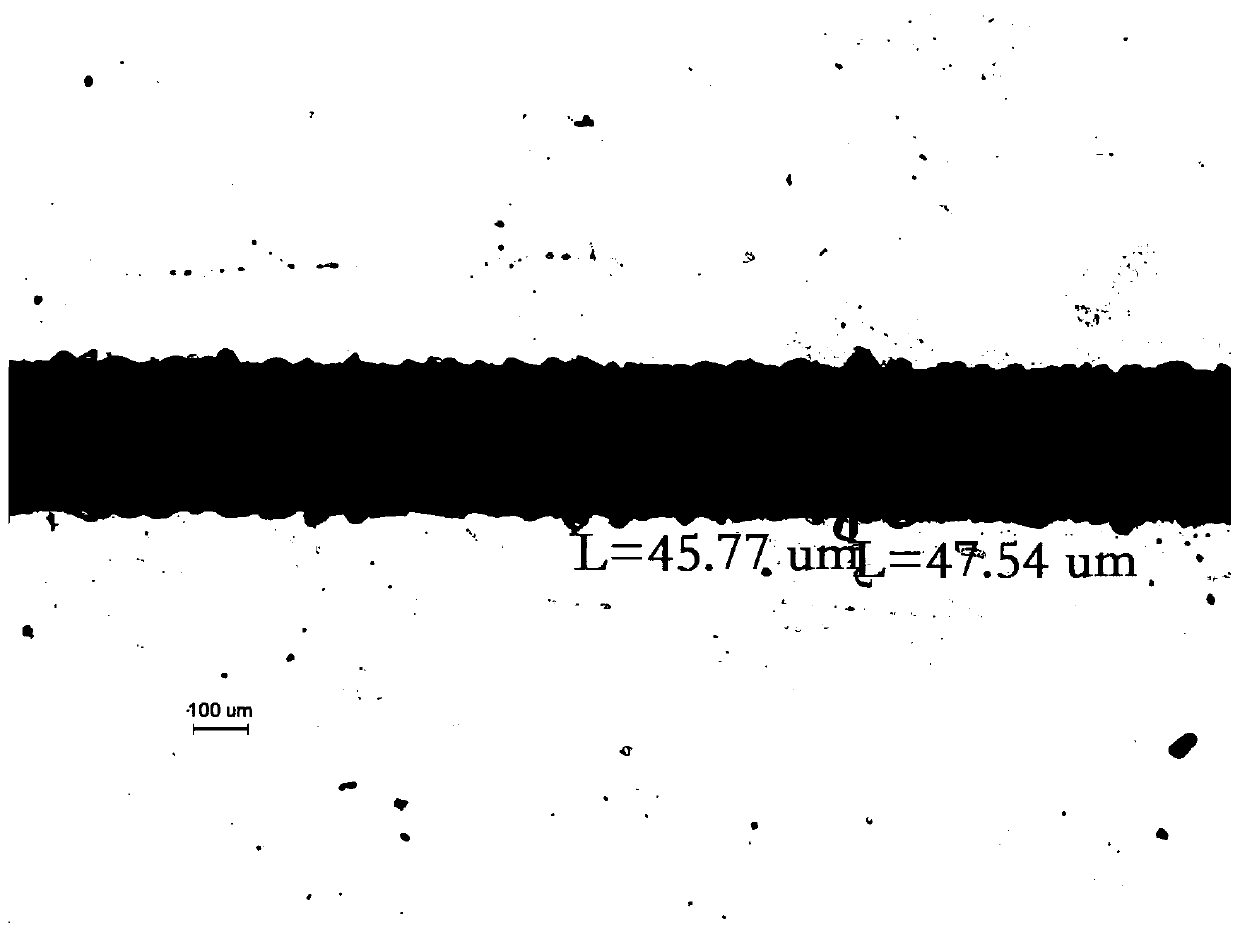

Method used

Image

Examples

Embodiment 1

[0036] The glass cutting resin grinding wheel of the present embodiment is a resin grinding wheel for quartz glass cutting, made of the following raw materials in parts by volume: 20 parts of self-sharpening diamond powder, 45 parts of phenolic resin, 15 parts of silicon carbide powder, and 10 parts of cerium oxide powder 5 parts, 5 parts of nickel powder, 5 parts of potassium sulfate.

[0037] Among them, the particle size of self-sharpening diamond powder is 325 / 400, the particle size of silicon carbide powder is W10, the particle size D50 of cerium oxide powder is 5.2 μm, the particle size of nickel powder is 10 μm, and the particle size of potassium sulfate is 50 μm.

Embodiment 2

[0039] The resin grinding wheel for glass cutting of the present embodiment is a resin grinding wheel for quartz glass cutting, made of the following raw materials in parts by volume: 15 parts of self-sharpening diamond powder, 40 parts of phenolic resin, 15 parts of silicon carbide powder, and 10 parts of cerium oxide powder Parts, 10 parts of nickel powder, 10 parts of potassium sulfate.

[0040]Among them, the particle size of self-sharpening diamond powder is 325 / 400, the particle size of silicon carbide powder is W10, the particle size D50 of cerium oxide powder is 5.2 μm, the particle size of nickel powder is 10 μm, and the particle size of potassium sulfate is 50 μm.

Embodiment 3

[0042] The resin grinding wheel for glass cutting of the present embodiment is a resin grinding wheel for quartz glass cutting, made of the following raw materials in parts by volume: 25 parts of self-sharpening diamond powder, 50 parts of phenolic resin, 10 parts of silicon carbide powder, 5 parts of cerium oxide powder 8 parts, 8 parts of nickel powder, 2 parts of sodium chloride.

[0043] Among them, the particle size of self-sharpening diamond powder is 325 / 400, the particle size of silicon carbide powder is W10, the particle size D50 of cerium oxide powder is 5.2 μm, the particle size of nickel powder is 10 μm, and the particle size of potassium sulfate is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com