Preparation method of nano cellulose/carbon nanotube flexible tactile sensor

A tactile sensor, nanocellulose technology, applied in sensors, catheters, measuring pulse rate/heart rate, etc., can solve the problems of high price, time-consuming, complicated preparation process, etc., and achieve low cost, high chemical stability, and preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

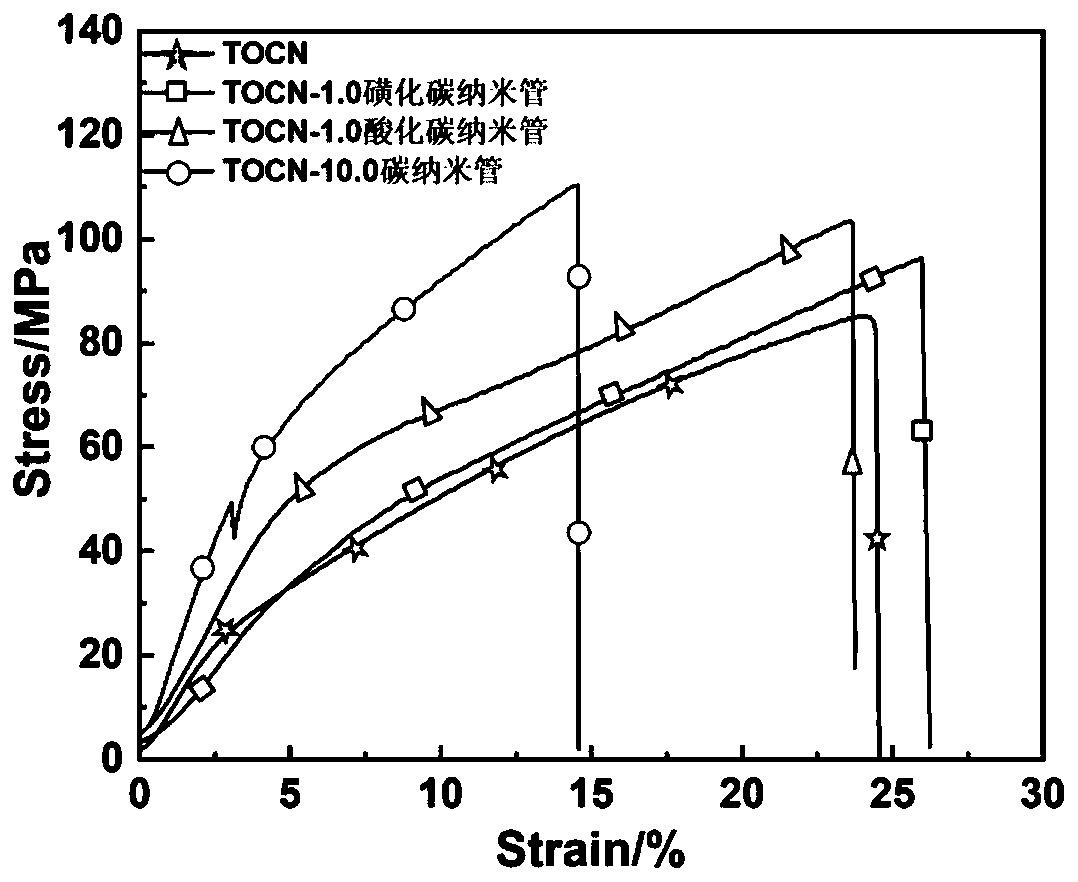

[0034] A nanocellulose / carbon nanotube composite flexible tactile sensor, the preparation method is as follows:

[0035] 1) Preparation of TOCN dispersion: oxidize cellulose wood pulp into cellulose nanofibers through TEMPO-mediated oxidation. The oxidized cellulose pulp is filtered, washed with deionized water for more than 3 times, and dried to obtain TEMPO oxidized cellulose (TOC). 0.1 g of TOC was added to 99.9 g of distilled water and mechanically stirred at 1800 r / min for 10 min to obtain a 0.1 wt % TOCN dispersion.

[0036] 2) Preparation of TOCN / carbon nanotube dispersion: adding carbon nanotubes to the nanocellulose dispersion prepared above, and then mixing the two at a mass ratio of 9.0:1.0. The mixing process is to repeat stirring and ultrasonication for 3 times, each time for 50 minutes, to ensure that the two are evenly mixed.

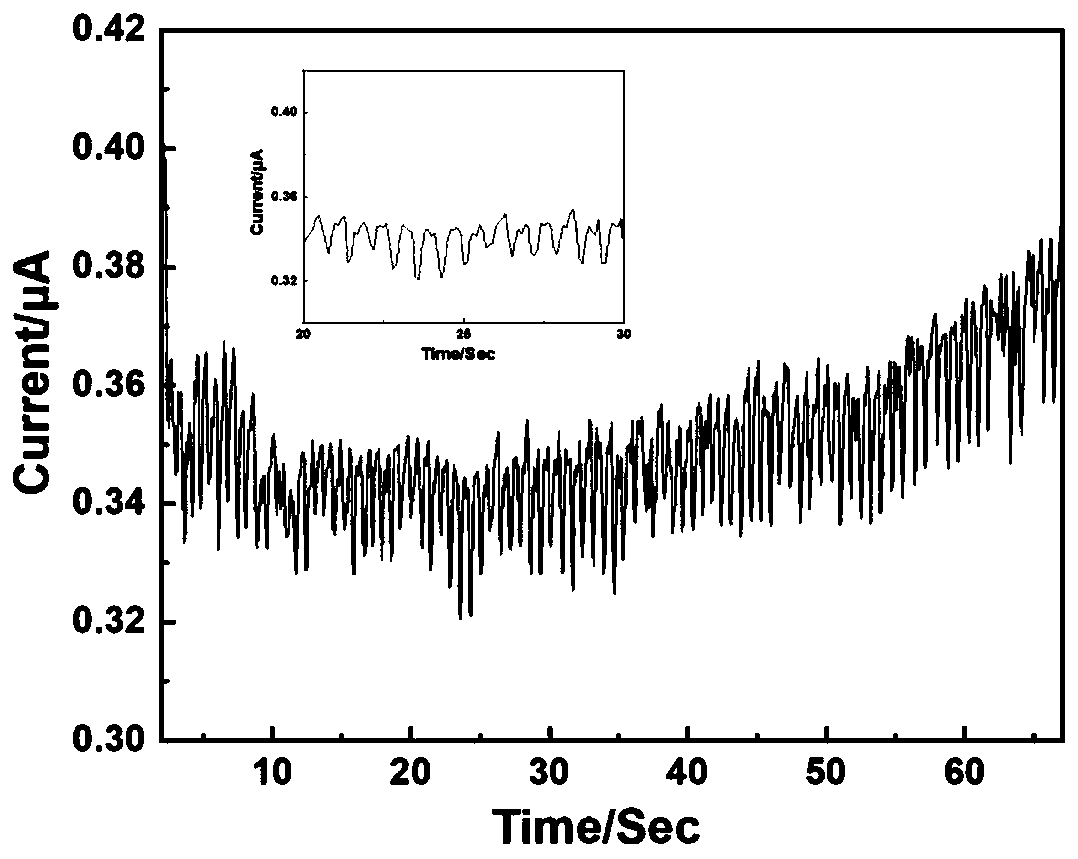

[0037] 3) Preparation of TOCN / carbon nanotube composite flexible tactile sensor hydrogel film: pour the above-mentioned TOCN / carbon na...

Embodiment 2

[0041] A nanocellulose / carbon nanotube composite flexible tactile sensor, the preparation method is as follows:

[0042] 1) Preparation of TOCN dispersion: oxidize cellulose wood pulp into cellulose nanofibers through TEMPO-mediated oxidation. The oxidized cellulose pulp is filtered, washed with deionized water for more than 3 times, and dried to obtain TEMPO oxidized cellulose (TOC). 0.1 g of TOC was added to 99.9 g of distilled water and mechanically stirred at 1800 r / min for 10 min to obtain a 0.1 wt % TOCN dispersion.

[0043] 2) Preparation of sulfonated carbon nanotubes: first prepare the diazonium salt solution, add a certain amount of carbon nanotubes to the prepared diazonium salt solution, ensure that the temperature is stirred at 0°C for 2 hours, and then stir the reaction at room temperature 24 hours. After the reaction was completed, the mixed solution was suction-filtered with a PTFE filter membrane with a pore size of 0.22 μm. Disperse with water, acetone and...

Embodiment 3

[0048] A nanocellulose / carbon nanotube composite flexible tactile sensor, the preparation method is as follows:

[0049] 1) Preparation of TOCN dispersion: oxidize cellulose wood pulp into cellulose nanofibers through TEMPO-mediated oxidation. The oxidized cellulose pulp is filtered, washed with deionized water for more than 3 times, and dried to obtain TEMPO oxidized cellulose (TOC). 0.1 g of TOC was added to 99.9 g of distilled water and mechanically stirred at 1800 r / min for 10 min to obtain a 0.1 wt % TOCN dispersion.

[0050] 2) Preparation of TOCN / acidified carbon nanotube dispersion: add acidified carbon nanotubes to the nanocellulose dispersion prepared above, and then mix the two at a mass ratio of 9.9:0.1. The mixing process is to repeat stirring and ultrasonication for 3 times, each time for 50 minutes, to ensure that the two are evenly mixed.

[0051] 3) Preparation of TOCN / acidified carbon nanotube composite flexible tactile sensor hydrogel film: pour the above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com