Antibacterial PVC pipe and preparation method thereof

A technology for PVC pipes and raw materials, applied in the field of antibacterial PVC pipes and their preparation, can solve the problems of poor antibacterial properties, poor processing thermal stability, toughness and strength, etc., achieve significant antibacterial effect, improve mechanical properties, and high toughness and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

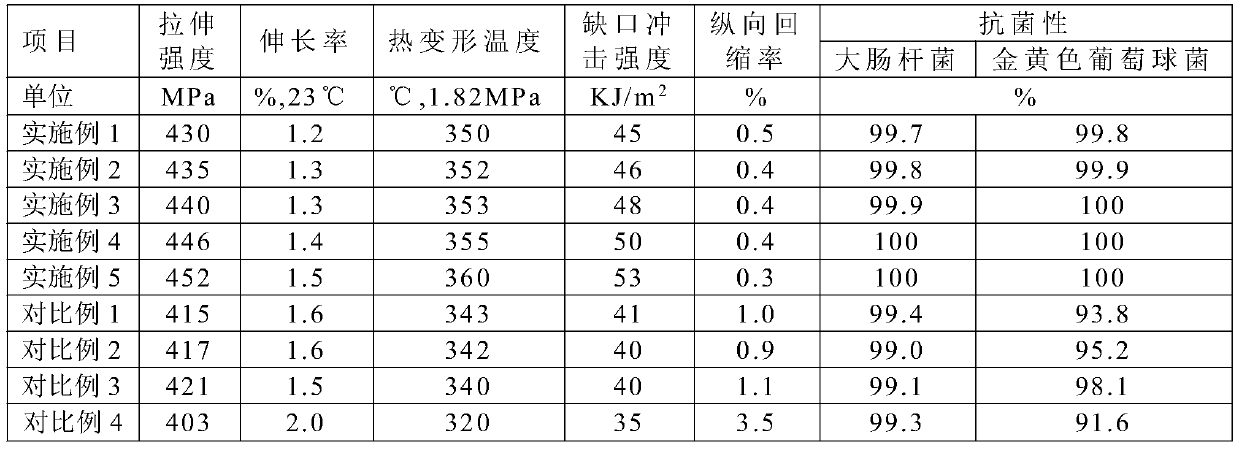

Examples

Embodiment 1

[0025] An antibacterial PVC pipe, made of the following raw materials in parts by weight: 90 parts of polyvinyl chloride, 20 parts of antibacterial functional copolymer, 10 parts of surface modified biomass carbon fiber / sepiolite powder / silver oxide composite, chitosan fiber 3 parts, 1 part of polyaminopropyl biguanide, 1 part of composite lead stabilizer, 3 parts of calcium stearate; The antibacterial functional copolymer is made of 7-[4-(4-fluorophenyl)-6-isopropyl Base-2-(N-methylmethylsulfonamido)-5-pyrimidine]-(3R)-tert-butyldimethylsilyloxy-5-oxo-(6E)-heptanoic acid methyl ester, (E) -3-(2-(1H-tetrazol-5-yl)vinyl)-6-fluoro-1H-indole, 1-allylhydantoin, 1-(4-pyridyl)-3-(2 -Quinolinyl)-2-propen-1-one, 3-(2,1,3-benzothiadiazol-5-yl)-3-hydroxy-2-propenoic acid ethyl ester prepared by free radical copolymerization .

[0026] The preparation method of the antibacterial functional copolymer comprises the steps of: 7-[4-(4-fluorophenyl)-6-isopropyl-2-(N-methylmethylsulfonyl)-5-...

Embodiment 2

[0030]An antibacterial PVC pipe, made of the following raw materials in parts by weight: 95 parts of polyvinyl chloride, 23 parts of antibacterial functional copolymer, 12 parts of surface modified biomass carbon fiber / sepiolite powder / silver oxide composite, chitosan fiber 4.5 parts, 1.5 parts of polyaminopropyl biguanide, 1.5 parts of calcium zinc stabilizer, 3.5 parts of stearic acid; the antibacterial functional copolymer is composed of 7-[4-(4-fluorophenyl)-6-isopropyl -2-(N-methylmethylsulfonylamido)-5-pyrimidine]-(3R)-tert-butyldimethylsilyloxy-5-oxo-(6E)-heptanoic acid methyl ester (CAS: 147118- 38-5), (E)-3-(2-(1H-tetrazol-5-yl)vinyl)-6-fluoro-1H-indole (CAS: 1316695-35-8), 1-allyl Hydantoin, 1-(4-pyridyl)-3-(2-quinolyl)-2-propen-1-one, 3-(2,1,3-benzothiadiazol-5-yl) - Ethyl 3-hydroxy-2-acrylate is produced by free radical copolymerization.

[0031] The preparation method of the antibacterial functional copolymer comprises the steps of: 7-[4-(4-fluorophenyl)-6-isopr...

Embodiment 3

[0035] An antibacterial PVC pipe, made of the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 25 parts of antibacterial functional copolymer, 13 parts of surface modified biomass carbon fiber / sepiolite powder / silver oxide composite, chitosan fiber 5 parts, 2 parts of polyaminopropyl biguanide, 2 parts of composite lead stabilizer, 4 parts of paraffin; The antibacterial functional copolymer is made of 7-[4-(4-fluorophenyl)-6-isopropyl-2 -(N-methylmethylsulfonamido)-5-pyrimidine]-(3R)-tert-butyldimethylsilyloxy-5-oxo-(6E)-heptanoic acid methyl ester (CAS: 147118-38- 5), (E)-3-(2-(1H-tetrazol-5-yl)vinyl)-6-fluoro-1H-indole (CAS: 1316695-35-8), 1-allyl sea In, 1-(4-pyridyl)-3-(2-quinolyl)-2-propen-1-one, 3-(2,1,3-benzothiadiazol-5-yl)-3 -Hydroxy-2-ethyl acrylate is prepared by free-radical copolymerization.

[0036] The preparation method of the antibacterial functional copolymer comprises the steps of: 7-[4-(4-fluorophenyl)-6-isopropyl-2-(N-methylme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com