Lubricating oil composition and its preparation method and the micro-quantity lubricating oil prepared by the combination

A lubricating oil composition and lubricating oil technology, applied in the field of lubrication, can solve problems such as affecting the health of operators, being unsuitable for the technical field of metal cutting processing, unfriendly to sulfur- and chlorine-containing additives, and the like, achieving remarkable environmental protection effects, The effect of good degradability and excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

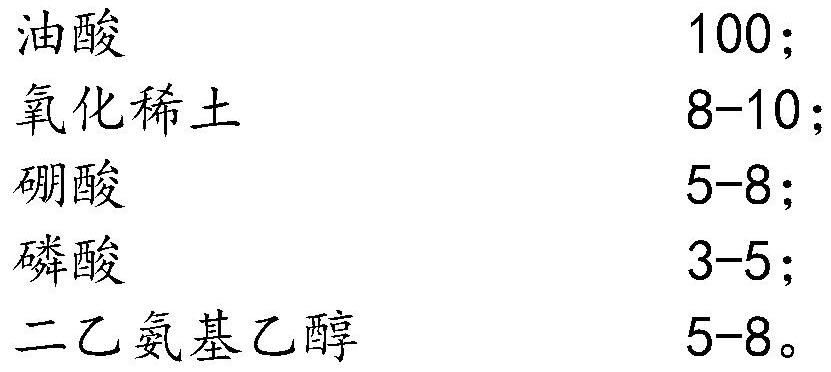

Embodiment 1

[0038] Step 1: Take 100 g of oleic acid, 10 g of cerium oxide, 8 g of boric acid, 5 g (effective concentration of 85%), and stirred to 120 ° C, stirring for 2 hours.

[0039] Step 2: When the temperature eliminates to 45 ° C or lower, the mixture was added to 2 hours to obtain a translucent substance, that is, a lubricating oil composition.

[0040] It is weighed with the above-mentioned lubricating oil composition 100g, ishylacetinate 800 g, and the polymethyl metodercyl ester 100g of polymethyl metorcrylate is mixed at 40 ° C.

[0041] Method for preparing the polymethyl metorciolate of polymethyl methacrylate:

[0042] Step 1: 86.09 g (1 mol) of methacrylic acid was added to the reaction kettle with a reaction temperature of 1 mol of n-calcium alcohol, and at 180 ° C reaction temperature was 5 h. Acetinate;

[0043] Step 2, the initiator peroxide is added to the reactor, stirred, the reaction temperature is 120 ° C, and the polymerization is 5 hours, and the polymer in the reac...

Embodiment 2

[0045] Step 1: Take 100 g of oleic acid, 8 g of cerium oxide, 5 g of boric acid, 10 g (effective concentration of 50%), and stirred to 100 ° C, stirring for 3 hours.

[0046] Step 2: When the temperature eliminates to 45 ° C or lower, the mixture was added to 1 hour, and the translucent substance was obtained, that is, a lubricating oil composition.

[0047] It is weighed with 50 g of the lubricant composition, ishylacetinate 750 g, and the polymethyl methacrylate 200 g is mixed at 60 ° C.

[0048] Method for preparing lycoool esters of polymethyl methacrylate:

[0049] Step 1: EtOAc EtOAc The pressure discharge moisture, that is, is a nichanol ester of methacrylate;

[0050] Step 2, the initiator tert-butyl hydrazine hydrazine is added to the reactor, and the reaction temperature is 100 ° C, and the polymerization reaction is 8 hours, and the polymer in the reaction kettle is discharged, and the temperature filtrate removal of temperature above 80 ° C. That is, the polymethyl met...

Embodiment 3

[0052] Step 1: Take 100 g of oleic acid, 9 g of lanthanum oxide, 6 g of boric acid, 8 g (effective concentration of 50%) together with stirring, stirring to 110 ° C, and reacted for 2.5 hours.

[0053]Step 2: When the temperature eliminates to 45 ° C or lower, the addition of diethyl ethanol 6g was stirred for 1.5 hours, and the translucent material was obtained, that is, a lubricating oil composition.

[0054] It is weighed with 60 g of the lubricating oil composition, ispulcate 790 g, and the polymethyl methacrylate 150g is mixed at 50 ° C at a temperature of 50 ° C to a trace lubricating oil.

[0055] Preparation method of polymethyl methacrylate lauryl ester:

[0056] Step 1: 86.09 g (1 mol) of methacrylic acid, 205.02 g (1.1 mol), 3 g (effective concentration of 50%), reactive at 200 ° C in the reaction temperature of 200 ° C for 4 hours; reaction pressure after reaction The moisture is discharged, that is, methacrylate, lauryl ester;

[0057] Step 2, adding the initiator cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com