Preparation method of oleophylic and hydrophobic magnetic polystyrene-polyurethane composite sponge

A polyurethane sponge, lipophilic and hydrophobic technology, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of high heat resistance requirements of raw material foam, difficult to control the reaction process, unfavorable production and application, etc., to achieve durable Low thermal requirements, high oil-water selectivity, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

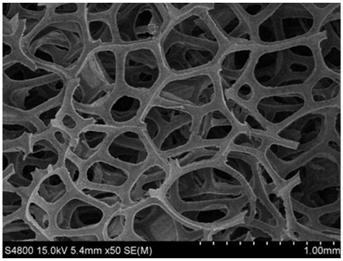

[0031] Embodiment 1: Preparation of lipophilic and hydrophobic magnetic polystyrene-polyurethane composite sponge

[0032] Weigh 150mg of nano-iron ferric oxide and 30ml of absolute ethanol in a small beaker, and ultrasonically disperse the system for 2 minutes. Cut the polyurethane sponge into a size of 1cm×1cm×3cm, then take one piece and add it to the above-mentioned beaker, and continue to sonicate for 10 minutes. Finally, the sponge was taken out and placed in an oven at a temperature of 60° C. to dry for 2 hours to obtain a magnetic polyurethane sponge.

[0033] Sequentially measure 6mL styrene and 0.3mL divinylbenzene and mix them uniformly in a quartz tube by ultrasonic for 2min. Take the above-mentioned dried magnetic polyurethane sponge and immerse it in the solution, protect it with nitrogen gas, and irradiate it with a high-pressure mercury lamp for 14h. Finally, wash the sponge thoroughly with toluene, ethyl acetate, and ethanol in sequence, and dry it in an oven...

Embodiment 2

[0037] Embodiment 2: Preparation of lipophilic and hydrophobic magnetic polystyrene-polyurethane composite sponge

[0038] Weigh 150mg of nano-iron ferric oxide and 30ml of absolute ethanol in a small beaker, and ultrasonically disperse the system for 2 minutes. Cut the polyurethane sponge into a size of 1cm×1cm×3cm, then take one piece and add it to the above-mentioned beaker, and continue to sonicate for 10 minutes. Finally, the sponge was taken out and placed in an oven at a temperature of 60° C. to dry for 2 hours to obtain a magnetic polyurethane sponge.

[0039] Sequentially measure 6mL styrene and 0.1mL divinylbenzene and mix them uniformly in a quartz tube by ultrasonic for 2min. Take the above-mentioned dried magnetic polyurethane sponge and immerse it in the solution, protect it with nitrogen gas, and irradiate it with a high-pressure mercury lamp for 14h. Finally, wash the sponge thoroughly with toluene, ethyl acetate, and ethanol in sequence, and dry it in an oven...

Embodiment 3

[0041] Embodiment 3: Preparation of lipophilic and hydrophobic magnetic polystyrene-polyurethane composite sponge

[0042] Weigh 150mg of nano-iron ferric oxide and 30ml of absolute ethanol in a small beaker, and ultrasonically disperse the system for 2 minutes. Cut the polyurethane sponge into a size of 1cm×1cm×3cm, then take one piece and add it to the above-mentioned beaker, and continue to sonicate for 10 minutes. Finally, the sponge was taken out and placed in an oven at a temperature of 60° C. to dry for 2 hours to obtain a magnetic polyurethane sponge.

[0043] Sequentially measure 6mL styrene and 0.5mL divinylbenzene and mix them uniformly in a quartz tube by ultrasonic for 2min. Take the above-mentioned dried magnetic polyurethane sponge and immerse it in the solution, protect it with nitrogen gas, and irradiate it with a high-pressure mercury lamp for 14h. Finally, wash the sponge thoroughly with toluene, ethyl acetate, and ethanol in sequence, and dry it in an oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

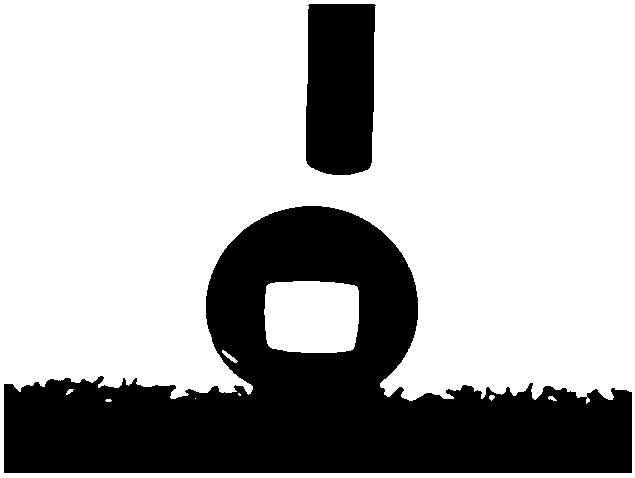

| Water contact angle | aaaaa | aaaaa |

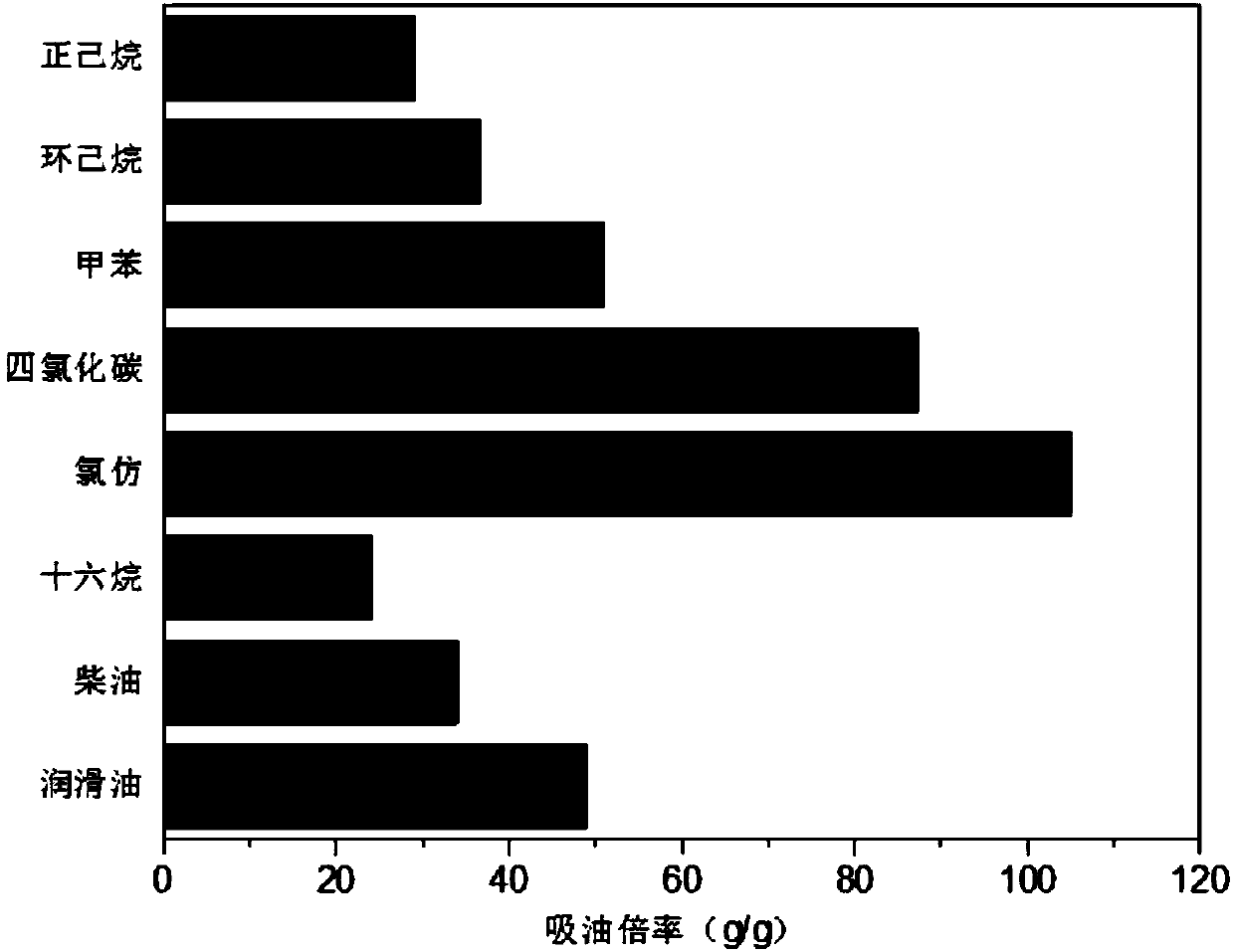

| Absorption rate | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com