Conductive hydrophobic membrane and preparation method thereof, and electrothermal membrane distillation assembly containing same

A hydrophobic membrane and electrothermal membrane technology, applied in the field of electrothermal membrane distillation components and conductive hydrophobic membranes, can solve the problems of large hydraulic cycle energy consumption, large heating energy consumption, and difficult drying process, so as to reduce heating energy consumption and simplify drying Good process and electric heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] According to some embodiments of the present invention, there is also provided a method for preparing the above conductive hydrophobic film, comprising the following steps:

[0044] (1) providing a hydrophobic microporous membrane;

[0045] (2) Forming a porous conductive layer on the hydrophobic microporous membrane.

[0046] In some embodiments, the porous conductive layer is graphene, and step (2) specifically includes the following sub-steps:

[0047] (2A) spraying the graphene oxide dispersion liquid on the surface of a hydrophobic microporous membrane multiple times, until the surface of the hydrophobic microporous membrane is completely covered by graphene oxide, and preparing a graphene oxide composite hydrophobic membrane;

[0048] Preferably, the graphene oxide dispersion is an aqueous dispersion, N,N-dimethylformamide dispersion or N,N-dimethylacetamide dispersion; the concentration of the dispersion is less than 10mg / mL, which is conducive to uniform spray ...

Embodiment 1

[0065] This embodiment provides a method for preparing a conductive hydrophobic membrane used in the electrothermal membrane distillation process, and the specific process is as follows:

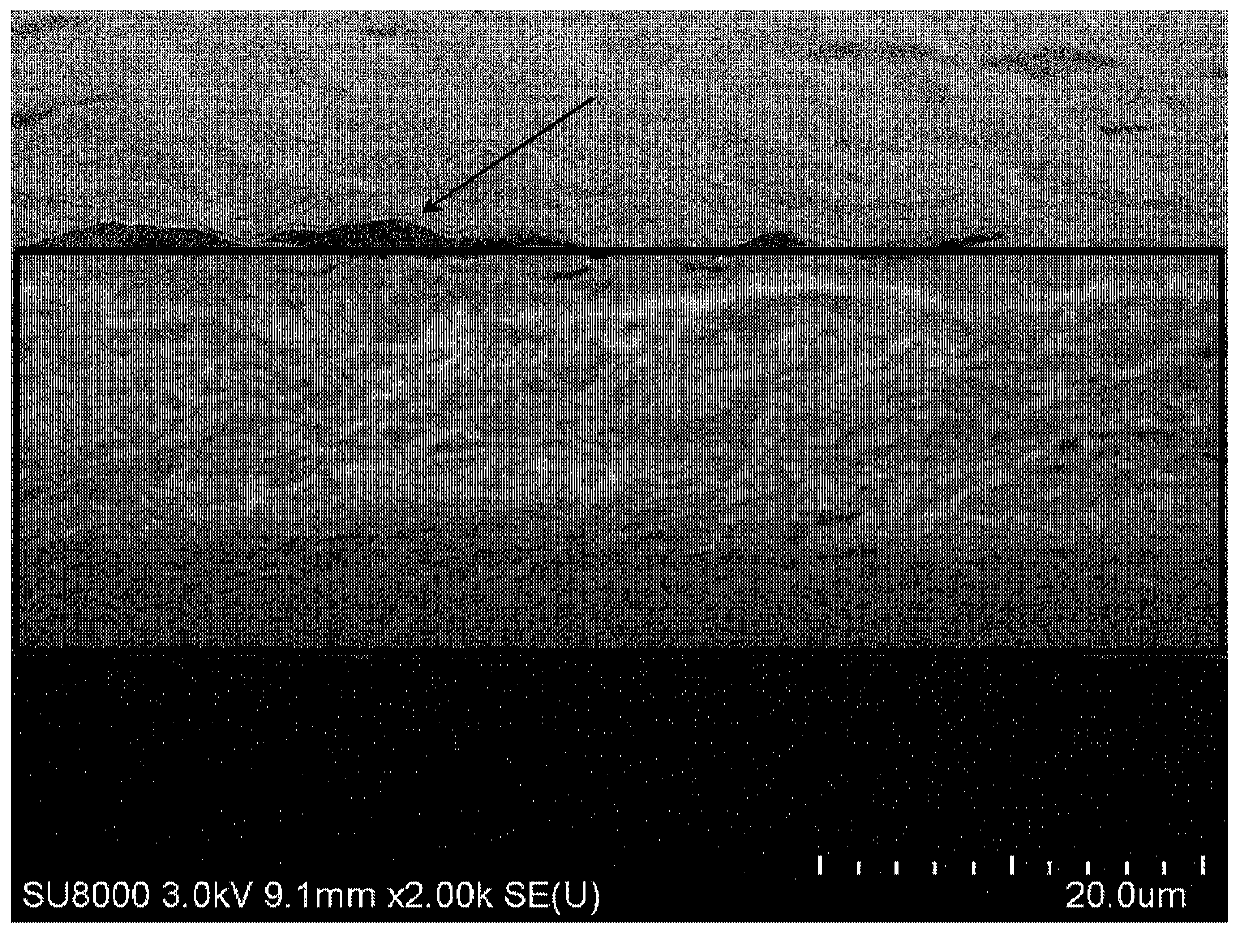

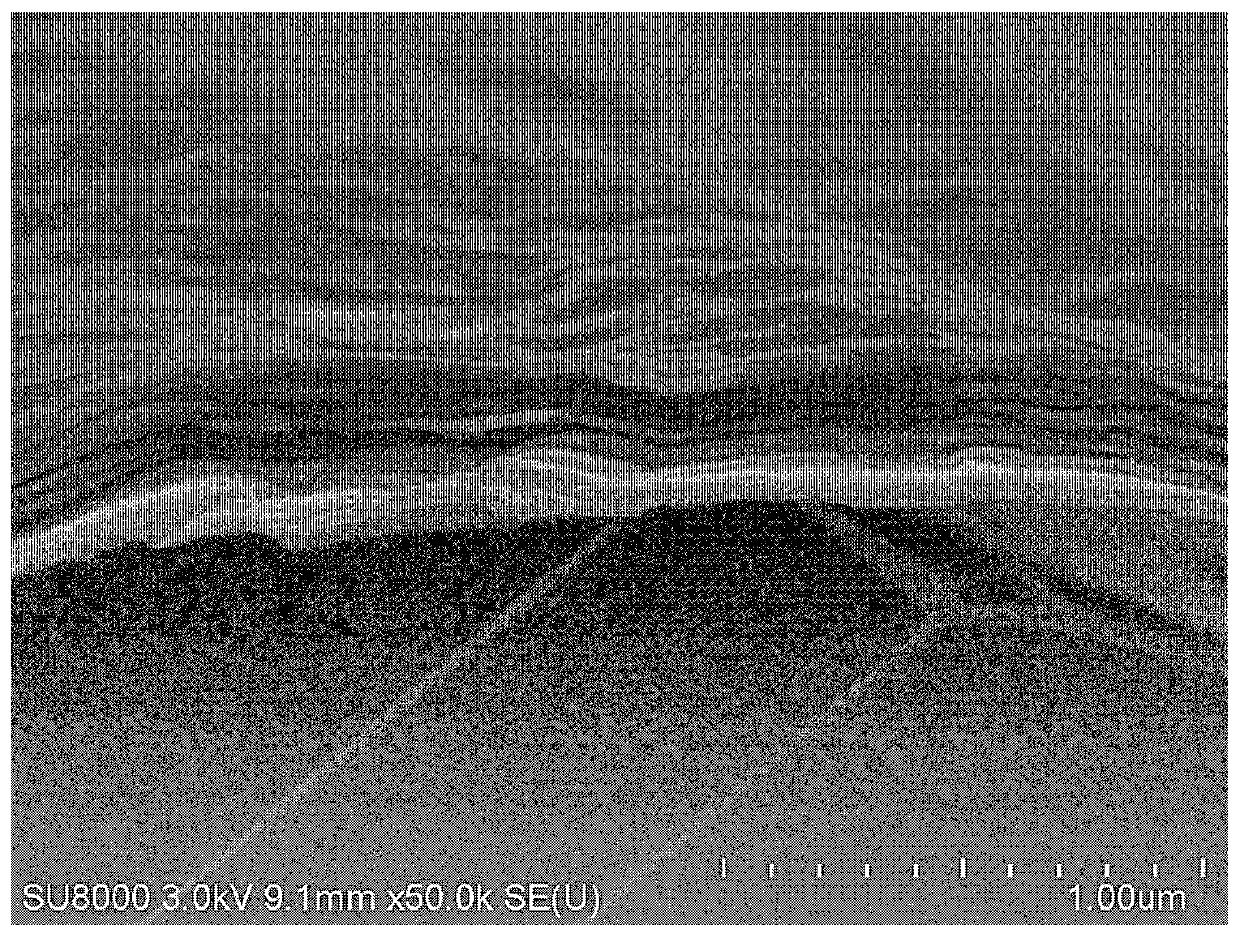

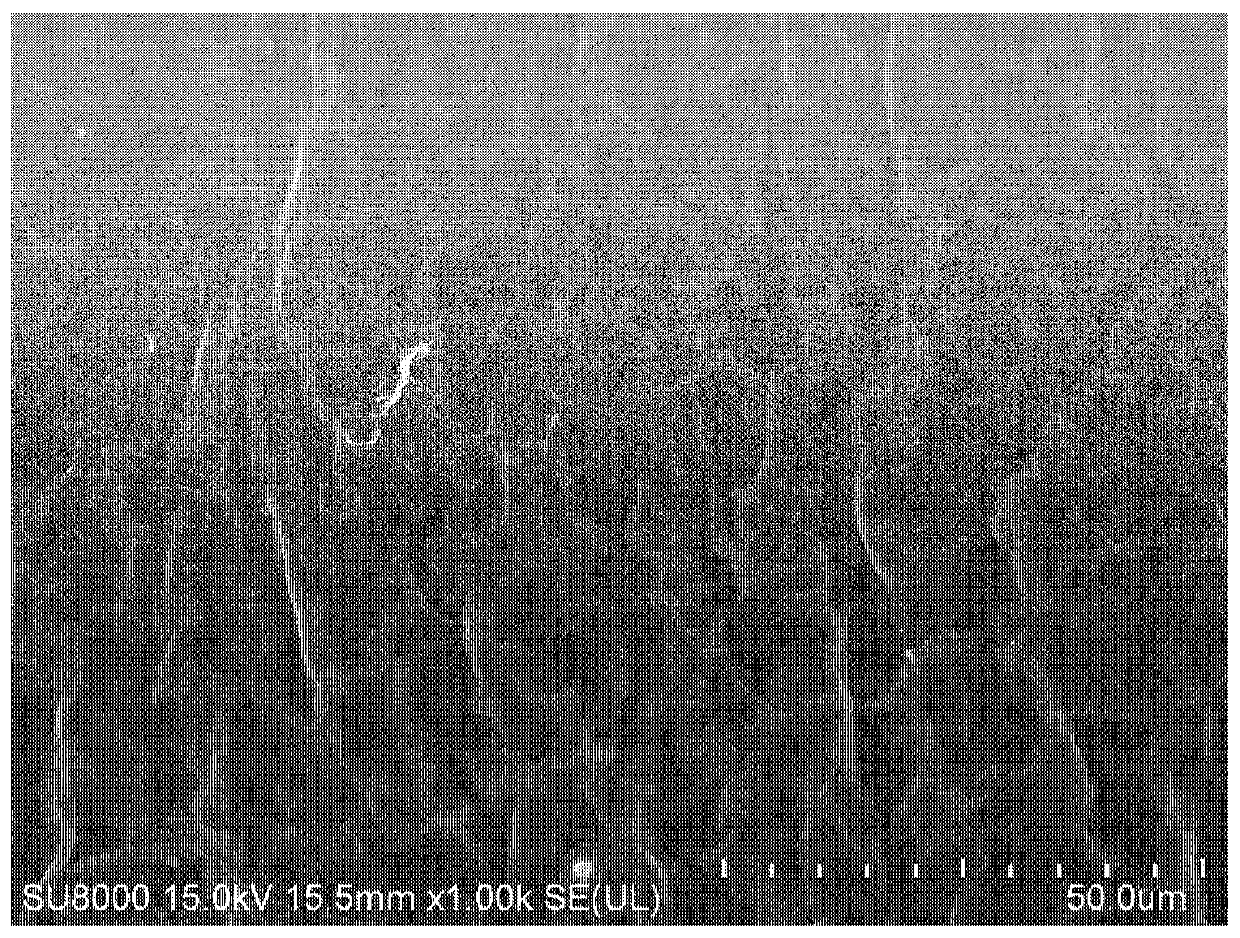

[0066] (1) The unsupported polytetrafluoroethylene hydrophobic microporous membrane (average pore diameter 0.22 μm, thickness about 30 μm, water contact angle about 140°, porosity 76%) is evenly pasted on the flat ceramic sheet surface; the ceramic The plate is placed on a flat temperature-controlled heater, with the microporous membrane side up, and the set temperature is 85°C;

[0067] (2) Spray 30mL of graphene oxide DMF (N, N-dimethylformamide) dispersion (concentration is 2mg / mL) evenly on the surface of hydrophobic microporous membrane with a sprayer, and then dry to prepare graphene oxide - Polytetrafluoroethylene composite hydrophobic membrane;

[0068] (3) Transfer the graphene oxide-polytetrafluoroethylene composite hydrophobic film to a tube furnace, and perform thermal reduction...

Embodiment 2

[0071] This embodiment provides a method for performing air-gap electrothermal film distillation using the conductive hydrophobic film as described above, comprising the following steps:

[0072] (1) The conductive hydrophobic membrane obtained in embodiment 1 is made into a flat membrane element, and assembled into a membrane module for electrothermal membrane distillation;

[0073] Among them, such as Figure 7 and 8(b) As shown, the two sides of the membrane element are the feed liquid side and the water production side respectively, and a cold wall is arranged on the water production side and the membrane element with an air gap. The hydrophobic microporous membrane layer of the conductive hydrophobic membrane is located on the feed liquid side, the graphene conductive layer is located on the water production side, and the cold wall side is fed with condensed water at 5°C. Condensed water is provided by water storage tank 9, and its circulation temperature is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com