Acid-resistant alkali-resistant high-whiteness daily-use ceramic product and preparation method thereof

A technology of acid and alkali resistance and ceramic products, which is applied in the field of ceramics, can solve the problems of poor acid and alkali resistance, poor whiteness, and limited application of ceramic products, and achieve good acid and alkali resistance, small color difference, and low production environment requirements. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

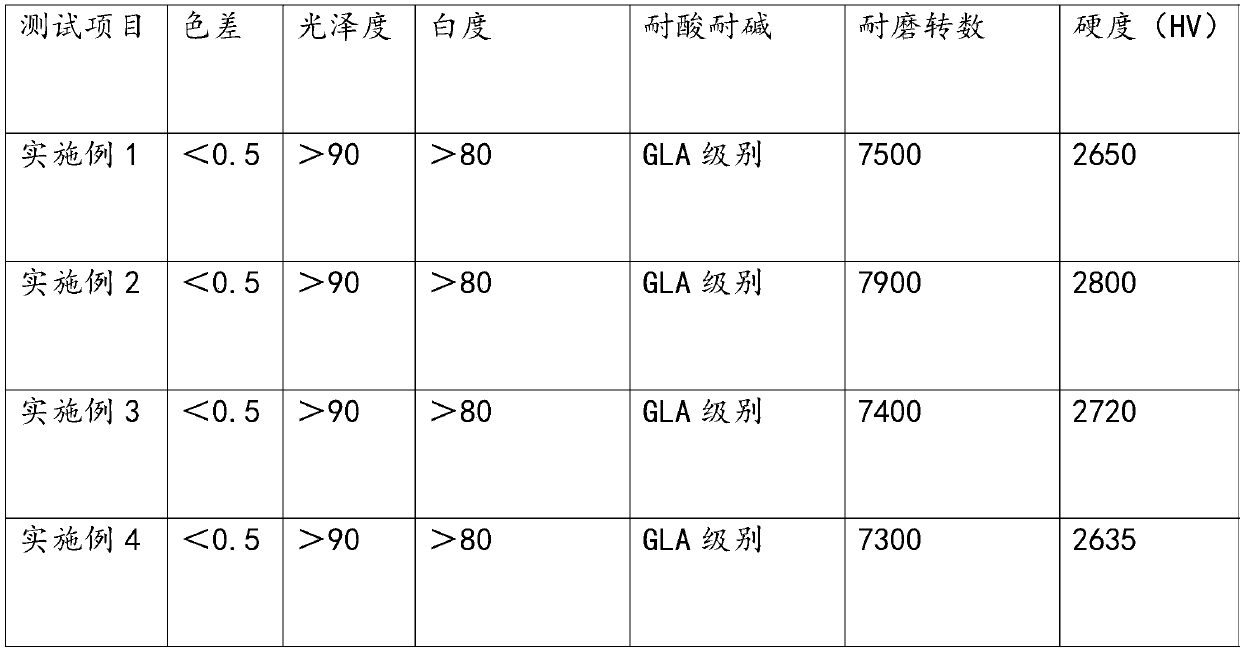

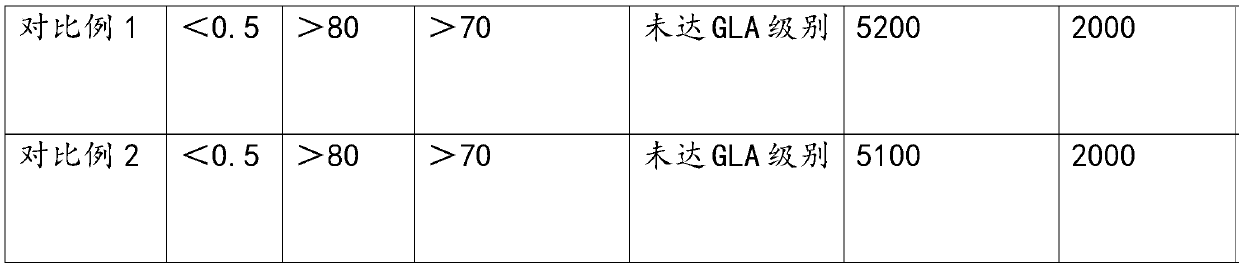

Examples

Embodiment 1

[0021] An acid and alkali-resistant high-whiteness daily-use ceramic product, comprising the following raw materials in parts by weight: 33 parts of potassium feldspar, 8 parts of quartz, 7 parts of spodumene, 3 parts of light calcium carbonate, 3 parts of zinc oxide, and 3 parts of titanium oxide 2.5 parts, 4 parts magnesium oxide, 2 parts borax, 1.5 parts sodium silicate, 2 parts calcium benzoate, 5 parts bisphenol A epoxy resin, 2.5 parts phenolic resin, 2 parts maleic anhydride and silane coupling agent KH -5601.5 copies.

[0022] A preparation method of acid and alkali-resistant high-brightness daily-use ceramic products, comprising the following steps:

[0023] S1. Quartz, potassium feldspar, and spodumene are heat-treated at 280 ° C for 9 min, naturally cooled to room temperature, and then crushed in a crusher to obtain crushed stone;

[0024] S2. described crushed stone, light calcium carbonate, zinc oxide, magnesium oxide, borax are mixed and ball-milled for 5h to ob...

Embodiment 2

[0029] An acid and alkali-resistant high-whiteness daily-use ceramic product, comprising the following raw materials by weight: 30 parts of potassium feldspar, 7 parts of quartz, 5 parts of spodumene, 2 parts of light calcium carbonate, 2 parts of zinc oxide, and 2 parts of titanium oxide 2 parts, 3 parts magnesium oxide, 1 part borax, 1 part sodium silicate, 1 part calcium benzoate, 3 parts bisphenol A epoxy resin, 1.5 parts phenolic resin, 1 part maleic anhydride and silane coupling agent KH -560 1 serving.

[0030] A preparation method of acid and alkali-resistant high-brightness daily-use ceramic products, comprising the following steps:

[0031] S1. Quartz, potassium feldspar, and spodumene are heat-treated at 250° C. for 8 minutes, naturally cooled to room temperature, and then crushed in a crusher to obtain crushed stone;

[0032] S2. described crushed stone, light calcium carbonate, zinc oxide, magnesium oxide, borax are mixed and ball-milled for 4h to obtain ball abr...

Embodiment 3

[0037] An acid and alkali-resistant and high-whiteness daily-use ceramic product, comprising the following raw materials by weight: 35 parts of potassium feldspar, 9 parts of quartz, 8 parts of spodumene, 4 parts of light calcium carbonate, 4 parts of zinc oxide, and 4 parts of titanium oxide 3 parts, 5 parts magnesium oxide, 3 parts borax, 2 parts sodium silicate, 3 parts calcium benzoate, 6 parts bisphenol A epoxy resin, 3 parts phenolic resin, 3 parts maleic anhydride and silane coupling agent KH -560 2 servings.

[0038] A preparation method of acid and alkali-resistant high-brightness daily-use ceramic products, comprising the following steps:

[0039] S1. Quartz, potassium feldspar, and spodumene are heat-treated at 320 ° C for 10 min, naturally cooled to room temperature, and then crushed in a crusher to obtain crushed stone;

[0040] S2. carry out mixed ball milling 4~6h with described crushed stone, light calcium carbonate, zinc oxide, magnesium oxide, borax, obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com