Process method for treating thiram sodium cobalt slag

A technology of cobalt fumarate slag and process method, which is applied in the direction of improving process efficiency, etc., can solve the problems of high equipment investment and production cost, and achieve the effects of reducing equipment investment, reducing cadmium content, and simplifying the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

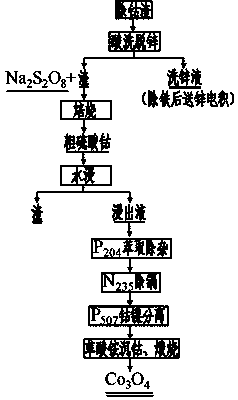

Method used

Image

Examples

Embodiment 1

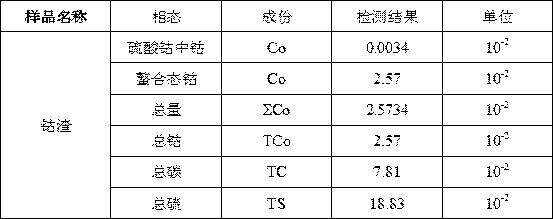

[0026] Example 1: Zinc was eluted with low-acid acid elution for the cobalt slag of forma in the composition table 1, the liquid-solid ratio (mL / g) was 1:1, normal temperature, the leaching time was 0.5 h, the temperature was 40°C, and the acidity of sulfuric acid was 100g / L, the extraction rate of zinc and iron is 97.2%, 92.4%; cobalt and cadmium are hardly dissolved (cobalt, cadmium and precipitant sodium formex are strongly chelated), the pickling slag contains 26.65% cobalt, and the slag rate is 24.7%;

[0027] Roasting of pickling slag: 200g of pickling slag, 10wt% sodium persulfate, 200°C calcination time, 0.5h calcination time; sulfation slag roasting at 300°C calcination temperature, 0.5h calcination time, calcination slag The rate is 30.78%;

[0028] Water leaching includes adding water to the crude cobalt sulfate obtained by roasting at a liquid-solid ratio of 10:1 for stirring and leaching. The reaction temperature is 90°C and the time is 2 hours. The slurry is vac...

Embodiment 2

[0032] Example 2: Zinc was eluted with low-acid acid elution for the cobalt slag of sodium formazan in the composition table 1, the liquid-solid ratio (mL / g) was 10:1, normal temperature, the leaching time was 2 h, the temperature was 70 °C, and the acidity of sulfuric acid was 10 g / L, the extraction rate of zinc and iron is 97.32% and 91.36%; cobalt and cadmium are almost not dissolved (cobalt, cadmium and precipitant sodium formex are strongly chelated), and the pickling slag contains 26.97% cobalt.

[0033] Oxidative roasting of pickling slag: pickling slag 200g, sodium persulfate added at 30wt%, roasting temperature 300 °C, roasting time 1 h; then heat up for sulfation roasting: roasting temperature 500 °C, roasting time 2 h, roasting The slag rate is 31.5%;

[0034] Water leaching includes adding water to the crude cobalt sulfate obtained by roasting at a liquid-solid ratio of 1:1, stirring and leaching, the reaction temperature is 40°C, and the time is 0.5h. Vacuum filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com