Preparation method of laminar self-assembly starfish type nickel-rich nickel telluride catalyst

A self-assembly, nickel telluride technology, applied in physical/chemical process catalysts, chemical instruments and methods, electrolytic components, etc., can solve the problems of poor hydrogen evolution catalytic activity, catalytic layer shedding, activity decline, etc., to increase the active specific surface area. , Improve roughness and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~2

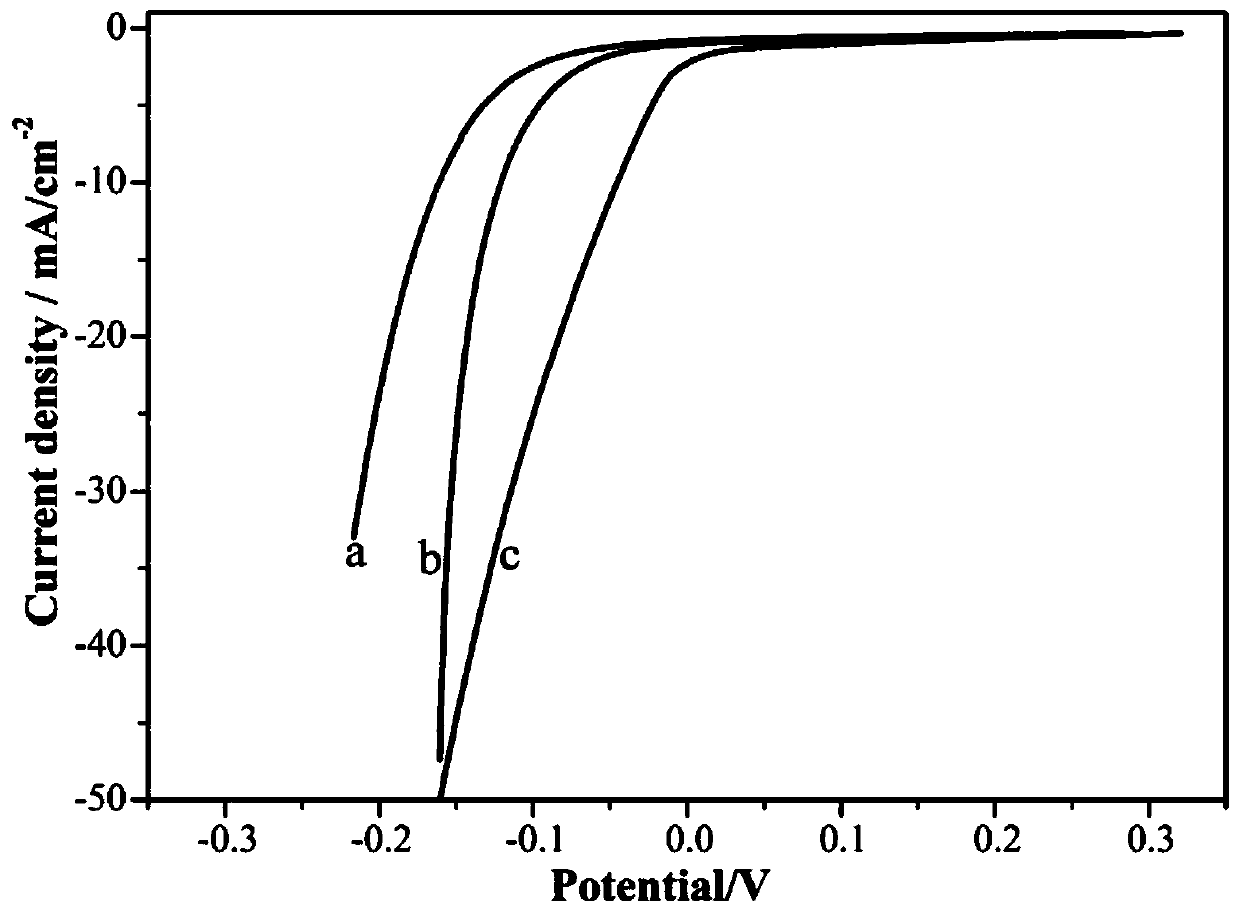

[0043] Now carry out test detection to embodiment 1~5 and comparative example 1~2:

[0044] 1. SEM detection:

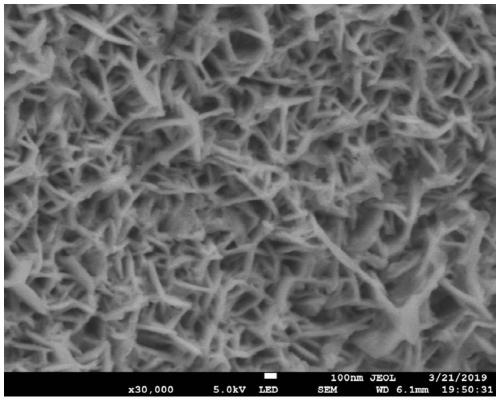

[0045] Scanning electron microscopy is used to detect the sheet-layer self-assembled starfish-shaped nickel-rich nickel telluride catalysts prepared in Examples 1 to 5. Taking Example 1 as an example, the test results are as follows figure 1 shown.

[0046] From figure 1 It can be observed that the surface of the nickel foam substrate forms a uniform sheet self-assembled starfish-like structure of nickel telluride, and this structure helps to increase the specific surface area of the catalyst, increase the number of active sites, and open vertical sheet structure It can also promote the transmission of the electrolyte and the timely diffusion of the gas products generated during the hydrogen evolution reaction, so that the catalyst has better hydrogen evolution performance.

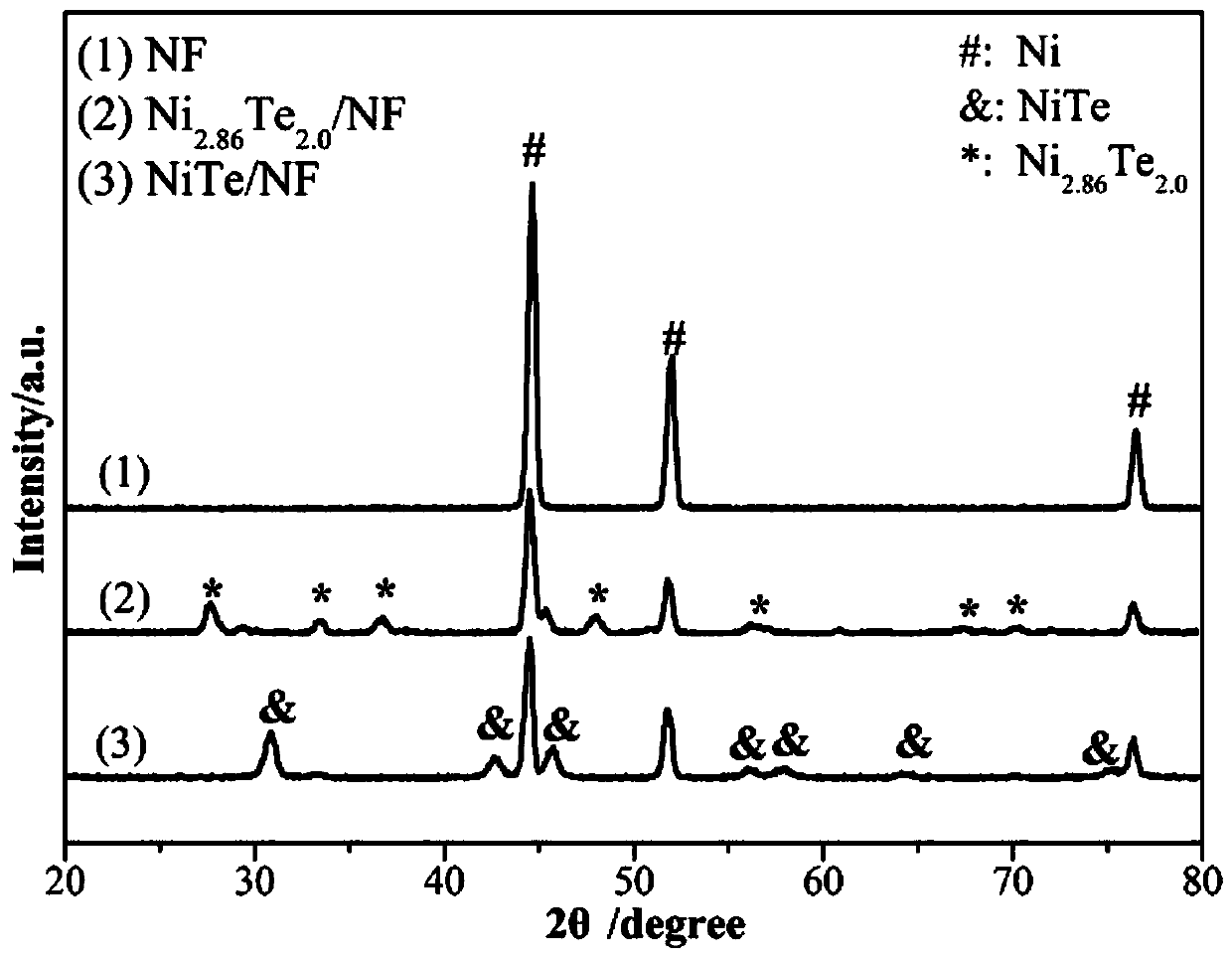

[0047] 2. XRD detection

[0048] Use X-ray diffractometer to detect the foamed nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com