Photochemical synthesis method of imidazolidine compound

A technology of photochemical synthesis and synthesis method, applied in the field of photochemical organic synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

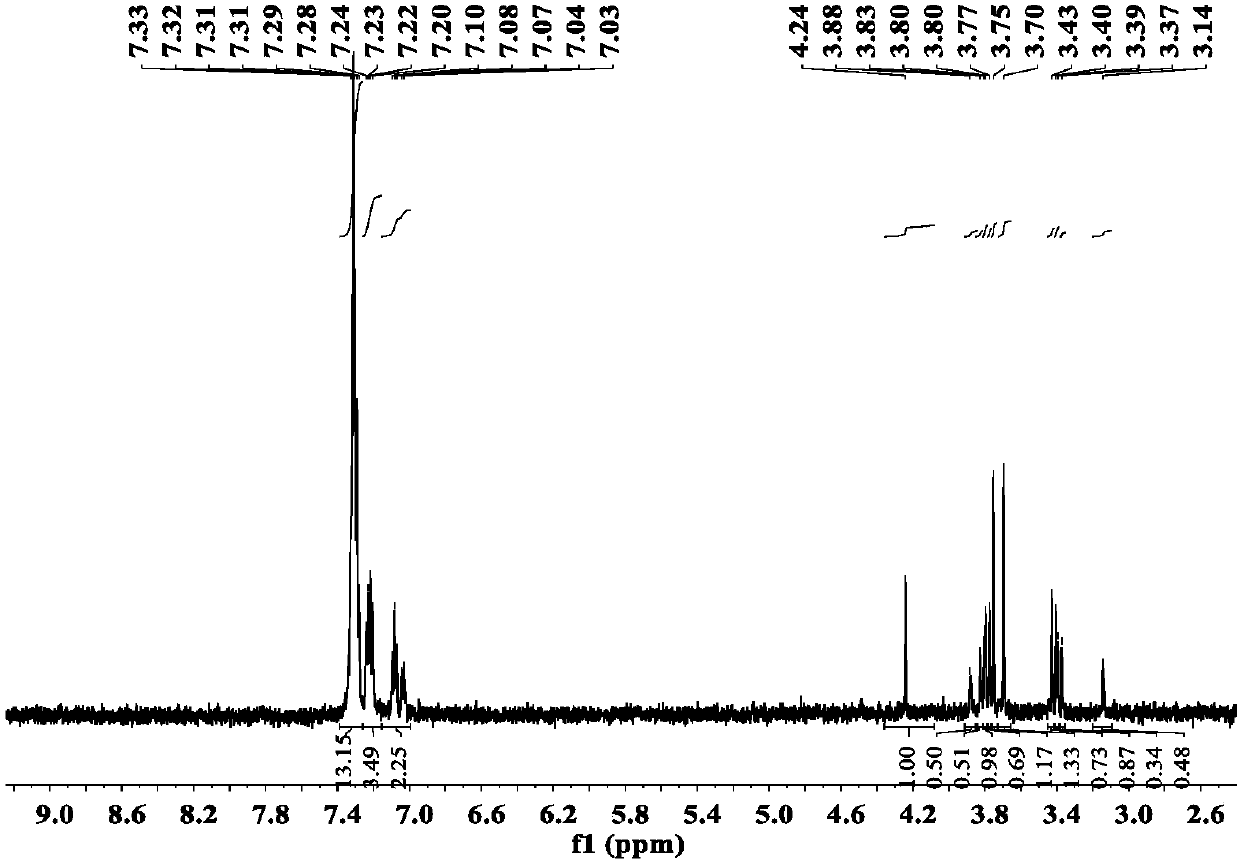

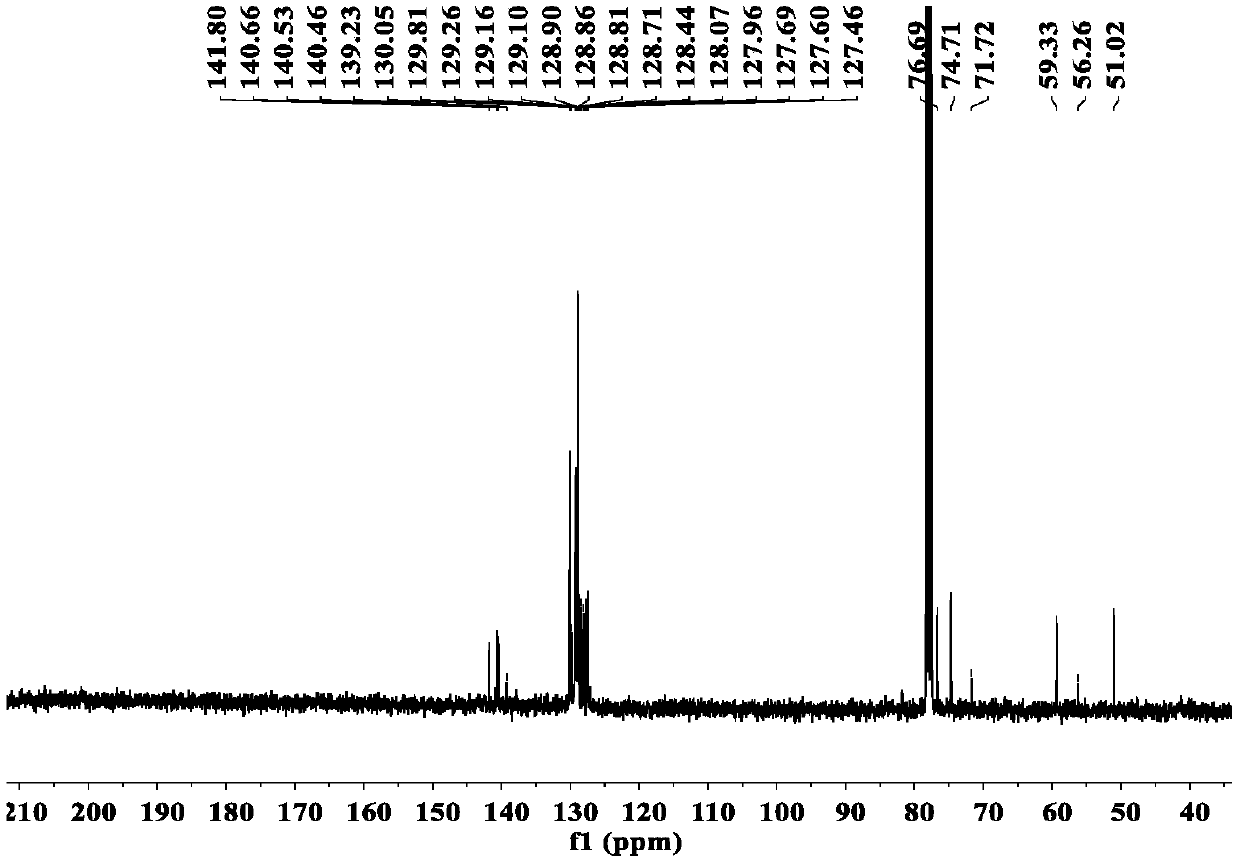

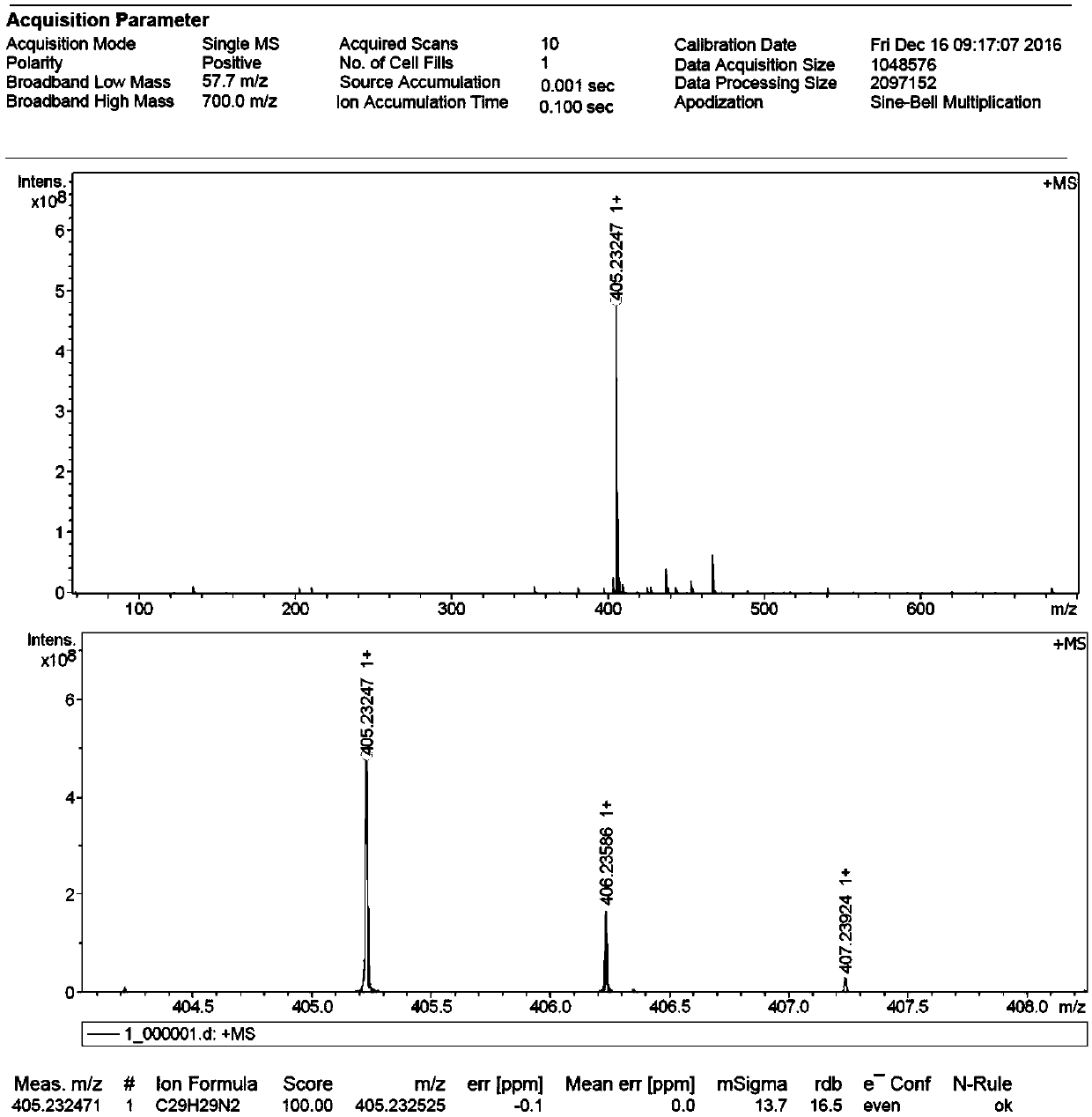

Embodiment 1

[0056] Mixed crystal P25 titanium dioxide and N-benzylidene benzylamine (PhCH=NCH 2 Ph) by 1:1 molar ratio (0.5mmol:0.5mmol) is added in the temperature-controlled transparent reaction bottle filled with methanol and temperature-controlled 25 ℃, so that the concentration of mixed crystal P25 titanium dioxide in the reaction system is 10g / L, the concentration of imine in the reaction system is 0.5mol / L, airtight and seal, pass in inert gas, make the inert gas pressure in the temperature-controlled transparent reaction bottle to be 0.01MPa, control the temperature to be 25 ℃ and stir for half an hour to make the sub The amine adsorption reached equilibrium, and then irradiated the temperature-controlled transparent reaction flask with a 300-watt xenon lamp and kept the temperature at 25 °C. After 24 hours of irradiation, the reaction was stopped, and the reaction product was separated by column chromatography. The reaction product was mainly shown in the following formula 1,3- ...

Embodiment 2

[0059] The anatase titanium dioxide and N-benzylidene benzylamine (PhCH=NCH 2Ph), ethanol is added in the temperature-controlled transparent reaction flask filled with acetonitrile at a molar ratio of 1:2:4 (0.25mmol:0.5mmol:1mmol) and the temperature is controlled at 25°C, so that anatase-type titanium dioxide is in the reaction system The concentration of ethanol in the reaction system is 1g / L, the concentration of ethanol in the reaction system is 2mol / L, the seal is closed, the inert gas is introduced, and the inert gas pressure in the temperature-controlled transparent reaction bottle is 0.01MPa, and the control temperature is 25 ℃ and Stir for half an hour to make the ethanol adsorption reach equilibrium, then irradiate the temperature-controlled transparent reaction flask with a 300-watt xenon lamp and keep the temperature at 25 °C, stop the reaction after 24 hours of irradiation, and separate the product by column chromatography. The reaction product is mainly shown in ...

Embodiment 3

[0062] The rutile titanium dioxide and N-benzylidenebenzylamine (PhCH=NCH 2 Ph), benzyl alcohol joins in the temperature-controlled transparent reaction flask filled with DMF by the molar ratio of 1:1:2 (0.5mmol:0.5mmol:1mmol), so that the concentration of rutile titanium dioxide in the reaction system is 2g / L, the concentration of imine in the reaction system is 0.5 mol / L, and the concentration of benzyl alcohol in the reaction system is 1 mol / L, airtightly seal the mouth, pass in inert gas, and make the inert gas pressure in the temperature-controlled transparent reaction bottle to be 0.01MPa, control the temperature to 25°C and stir for half an hour to make the adsorption of benzyl alcohol and imine reach equilibrium, then irradiate the temperature-controlled transparent reaction flask with sunlight and keep the temperature at 25°C, stop the reaction after 20 hours of irradiation, and separate the product by column chromatography , the reaction product is mainly 1,3-dibenz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com