A kind of v-ti-ni based porous hydrogen evolution cathode material, preparation method and application

A hydrogen evolution cathode and porous material technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of easy dissolution and damage of components, achieve the effect of protecting electrode materials, reducing reaction activation energy, and large hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

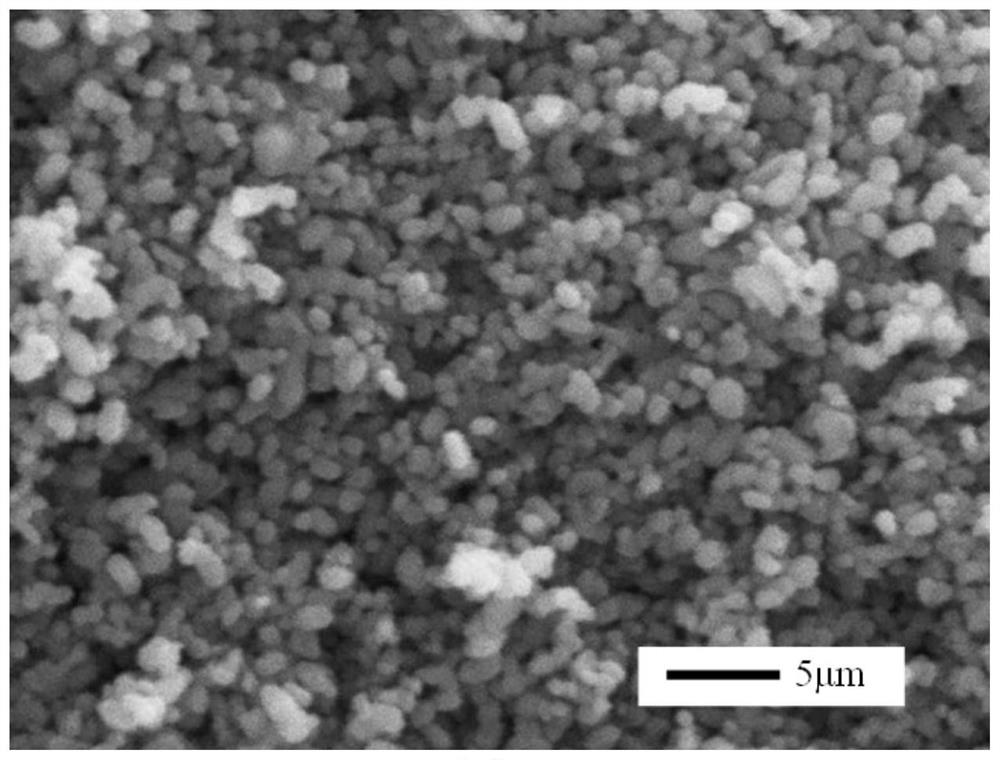

[0036] Step 1: Mix vanadium pentoxide, titanium dioxide, nickel powder, and aluminum-magnesium alloy powder (reducing agent) at a molar ratio of 1:1:0.67:4.68, and add additives such as calcium oxide, cryolite and magnesium oxide. The amount of calcium oxide is The amount of the aluminum-magnesium alloy is 30wt%, the amount of cryolite is 5wt% of the amount of the aluminum-magnesium alloy, the amount of magnesium oxide is 1wt% of the amount of the aluminum-magnesium alloy, and the amount of the potassium chlorate exothermic agent is 8wt% of the total amount of other materials. The mixed material is put into an induction furnace, ignited and smelted for 10 minutes, and the argon-loaded refining agent calcium fluoride is blown into the bottom of the melt for refining, and the amount of calcium fluoride is 2 wt% of the total charge. After refining for 10 minutes, pour it into a water-cooled copper crucible to obtain V 59 Ti 21 Ni 20 alloy.

[0037] The hydrogen absorption and ...

Embodiment 2

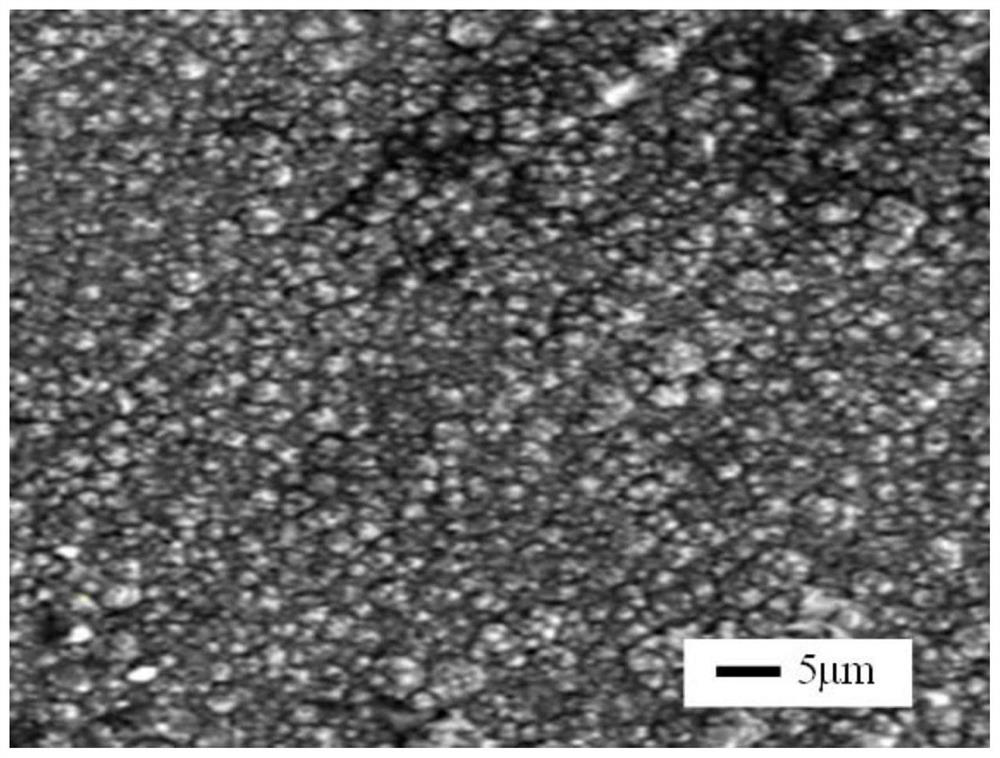

[0042] Step 1: Mix vanadium pentoxide, titanium dioxide, nickel powder, chromium oxide powder, and aluminum-calcium alloy powder in a molar ratio of 1:2.5:2:0.3:7.2, and add additives. The amount of calcium oxide is the amount of aluminum-calcium alloy The amount of cryolite is 10wt% of the amount of aluminum-calcium alloy, the amount of magnesium oxide is 5wt% of the amount of aluminum-calcium alloy, and the amount of potassium chlorate exothermic agent is 10wt% of the total amount of other materials. The mixed material is put into an induction furnace, ignited and smelted for 15 minutes, and calcium fluoride loaded with argon gas is blown into the bottom of the melt for refining, and the amount of calcium fluoride is 3wt% of the total amount of the furnace material. After refining for 15 minutes, pour it in a water-cooled copper crucible to obtain Ti 28 V 33 Cr 9 Ni 30 alloy ingot. The hydrogen absorption and desorption performance test of the alloy is the same as in Exa...

Embodiment 3

[0047] Step 1: Mix vanadium pentoxide, titanium dioxide, nickel powder, iron filings, and aluminum-calcium alloy at a molar ratio of 1:2.5:2:0.65:6.5, and add additives. The amount of calcium oxide is 35wt of the amount of aluminum-calcium alloy %, the amount of cryolite is 10wt% of the amount of aluminum-calcium alloy, the amount of magnesium oxide is 5wt% of the amount of aluminum-calcium alloy, and the amount of potassium chlorate exothermic agent is 10wt% of the total amount of other materials. The mixed material is put into an induction furnace, ignited and smelted for 15 minutes, and calcium fluoride loaded with argon gas is blown into the bottom of the melt for refining, and the amount of calcium fluoride is 3wt% of the total amount of the furnace material. After refining for 15 minutes, pour it in a water-cooled copper crucible to obtain Ti 29 V 31 Fe 10 Ni 30 alloy ingot. The hydrogen absorption and desorption performance test of the alloy is the same as in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com