Rubber/fluoroplastic composite resealing shock insulator and preparation method thereof

A fluoroplastic and resealing technology, applied in the field of rubber/fluoroplastic composite resealing septum and its preparation, can solve the problem that the fluoroplastic layer and the rubber layer are easily separated, the resealability of the septum cannot meet the requirements, and the needling perforation It is not easy to seal and other problems, so as to reduce the escape of residual components, meet the requirements of multiple injections, and meet the effect of long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

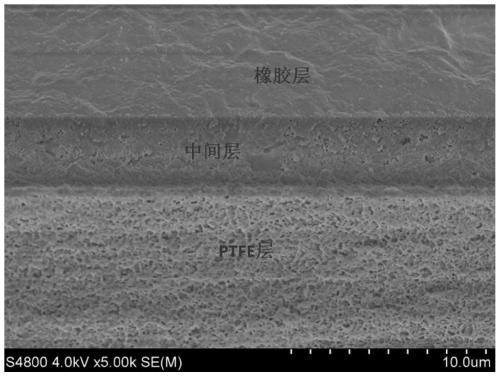

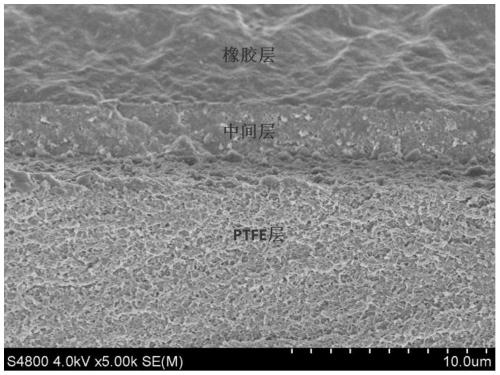

[0056] The resealable septum of this example consists of a rubber layer (methyl vinyl silicone rubber compound, 0.5 mm thick), an intermediate layer (silicone epoxy resin, 7 microns thick), and a fluoroplastic layer (PTFE, 0.5 mm thick). 27 microns), and obtained by the following preparation method:

[0057] (1) Coat silicone epoxy resin on the surface of PTFE and mold it at 260°C and 18MPa to obtain a composite film;

[0058] (2) Preparation of the rubber layer: weighing 100 parts of methyl vinyl silicone rubber, 0.5 parts of zinc stearate, 0.3 parts of white carbon black, 0.3 parts of color masterbatch, 1 part of dicumyl peroxide (DCP), iron oxide 3 parts of red, 3 parts of hydroxy silicone oil; mix well, then knead and release the film to form a regular film that is easy to vulcanize;

[0059] (3) Preparation of film-coated film: Cover the composite film obtained in step (1) on the surface of the rubber layer, with the silicone-coated side facing the rubber layer. Vulcani...

Embodiment 2

[0065] The resealing septum of embodiment 2-8, wherein the thickness of the rubber layer of embodiment 2 is 0.5 mm, the thickness of the middle layer is 5 microns, and the thickness of the fluoroplastic layer is 22 microns; the thickness of the rubber layer of embodiment 3 is 0.8 mm, the thickness of the middle layer The thickness of the layer is 9 microns, and the thickness of the fluoroplastic layer is 30 microns; the thickness of each layer of Embodiment 4-8 is the same as that of Embodiment 3, and the rubber layer material components and corresponding parts by weight of Embodiment 2-8 are as shown in Table 1 Shown, others are identical with embodiment 1.

[0066] Table 1. Embodiment 2-8 rubber layer material components and corresponding parts by weight thereof

[0067]

[0068]

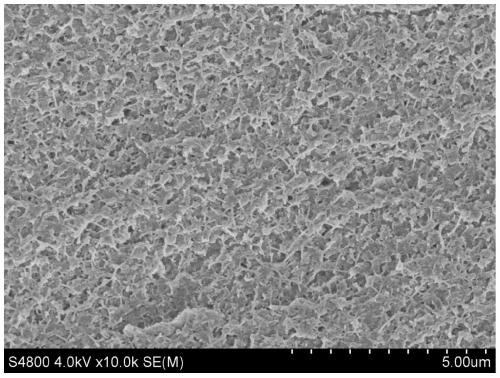

[0069] The resealing septum obtained in embodiment 2-8 is a three-layer structure, and the scanning electron microscope picture of the septum section in embodiment 2 is as follows image 3 ...

Embodiment 9-15

[0073] The difference between the resealable septa of Examples 9-15 and Example 1 is that the molding process, vulcanization process and drying process are different. Table 3 shows the differences in molding temperature and pressure, vulcanization temperature and pressure, secondary vulcanization temperature and pressure, and drying temperature between the rubber layer and the PTFE layer.

[0074] Processing technology among the table 3. embodiment 9-15

[0075]

[0076]

[0077] The resealable septum obtained in Examples 9-15 has a three-layer structure, and the bonding strength between the PTFE layer and the rubber layer is shown in Table 4.

[0078] The adhesive strength of PTFE layer and rubber layer among the table 4. embodiment 9-15

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com