Method for recovering silicon and germanium from germanium-containing optical fiber waste

A technology of optical fiber and silicon germanium, which is applied in the field of silicon germanium recycling and reuse, can solve the problems of low germanium recovery rate, environmental pollution, and a large amount of other waste and waste liquid, so as to improve the leaching rate and leaching speed, reduce the reaction temperature, and save the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

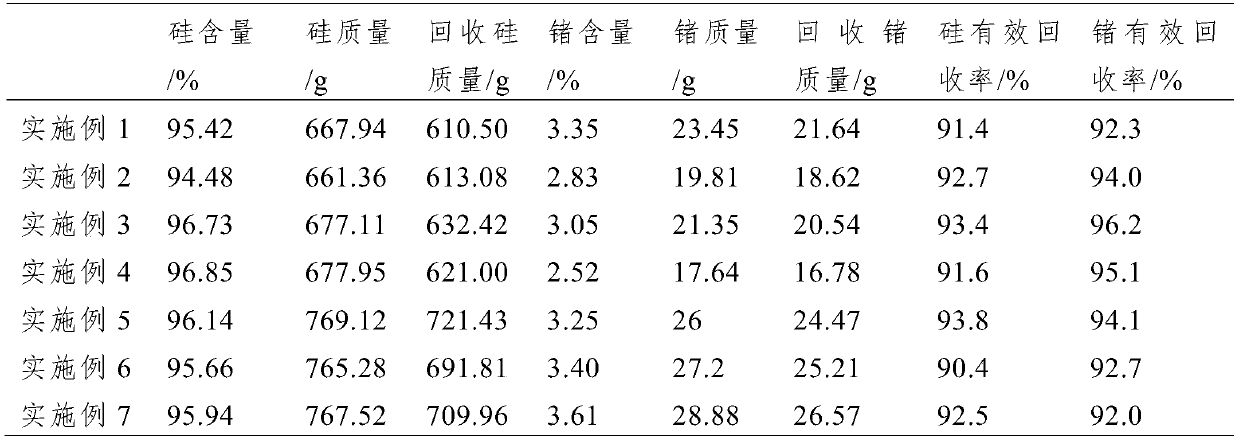

Embodiment 1

[0031] The method for reclaiming silicon germanium from germanium-containing optical fiber waste in this embodiment comprises the following steps:

[0032] Step 1, putting germanium-containing optical fiber waste into a crusher for crushing for 2 hours, and sieving the crushed germanium-containing optical fiber waste to obtain germanium-containing optical fiber waste powder with a particle size of 150 meshes;

[0033] Step 2. Mix 100g of the germanium-containing optical fiber waste powder described in step 1 with 500g of water for beating, add soluble alkali to the obtained slurry, and microwave the slurry with soluble alkali to 90°C under vacuum conditions and then keep the temperature constant 2h, filter, obtain silicon-germanium-containing leaching solution, take a sample and carry out ICP analysis, obtain the content of silicon in the silicon-germanium-containing leaching solution to be 95.42%, and the content of germanium is 3.35%; The quality of described soluble alkali i...

Embodiment 2

[0040] The method for reclaiming silicon germanium from germanium-containing optical fiber waste in this embodiment comprises the following steps:

[0041] Step 1, putting germanium-containing optical fiber waste into a crusher for crushing for 6 hours, and sieving the crushed germanium-containing optical fiber waste to obtain germanium-containing optical fiber waste powder with a particle size of 200 mesh;

[0042] Step 2. Mix 100g of the germanium-containing optical fiber waste powder described in step 1 with 500g of water for beating, add soluble alkali to the obtained slurry, and microwave the slurry with soluble alkali to 100°C under vacuum conditions, then keep the temperature constant 8h, filter to obtain silicon-germanium-containing leaching solution, take a sample and carry out ICP analysis, obtain that the content of silicon in the silicon-germanium-containing leaching solution is 94.48%, and the content of germanium is 2.83%; the quality of the soluble alkali is 0.25...

Embodiment 3

[0049] The method for reclaiming silicon germanium from germanium-containing optical fiber waste in this embodiment comprises the following steps:

[0050] Step 1, putting germanium-containing optical fiber waste into a crusher for crushing for 4 hours, and sieving the crushed germanium-containing optical fiber waste to obtain germanium-containing optical fiber waste powder with a particle size of 250 meshes;

[0051] Step 2. Mix 100g of the germanium-containing optical fiber waste powder described in step 1 with 500g of water for beating, add soluble alkali to the obtained slurry, and microwave the slurry with soluble alkali to 110°C under vacuum conditions, then keep the temperature constant 3h, filter to obtain silicon-germanium-containing leaching solution, take a sample and carry out ICP analysis, obtain that the content of silicon in the silicon-germanium-containing leaching solution is 96.73%, and the content of germanium is 3.05%; the quality of the soluble alkali is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com