An underwater transparent porous cellulose paper-based material for cell culture and its preparation method and application

A technology for porous cellulose and cell culture, which is applied in the field of underwater transparent porous cellulose paper-based materials and their preparation, and can solve the problems of limiting the application of transparent cellulose paper, low resolution of cell images, and limiting the application of paper-based materials. , to achieve the effect of low cost, abundant sources, simple and effective preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 2 g of microcrystalline cellulose, add 20 mL of N,N-dimethylacetamide (DMAC), stir and activate at 130°C for 30 min, and then cool to room temperature. Add 6 g of lithium chloride and 80 mL of DMAC to the cooled cellulose, and heat and stir at 60° C. until the microcrystalline cellulose dissolves.

[0036] (2) Grinding sodium chloride (NaCl) with a mortar, and screening out NaCl particles with a size smaller than 45 μm.

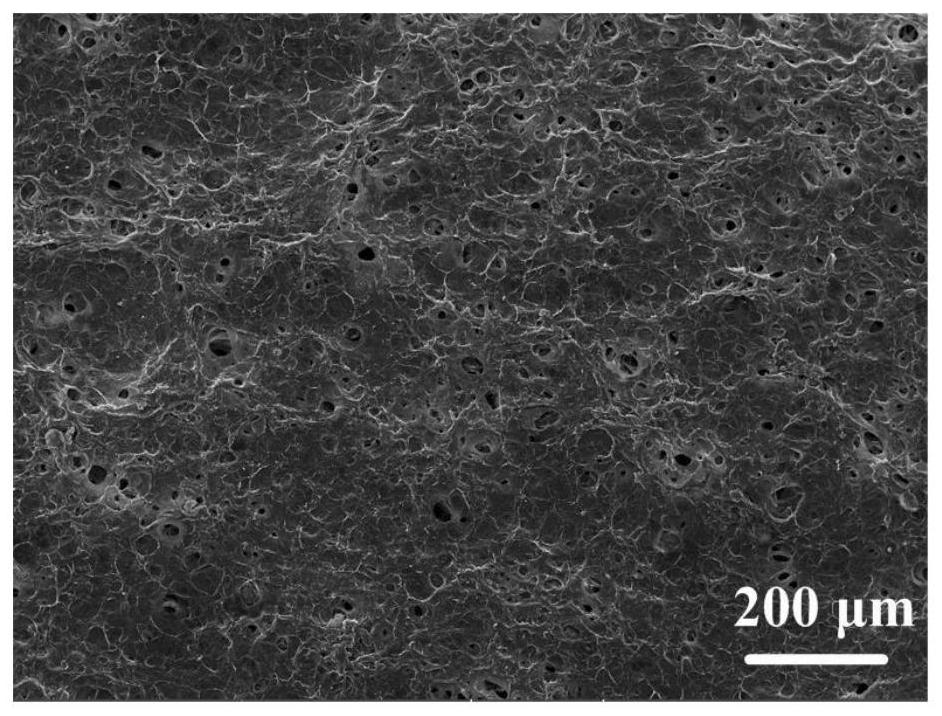

[0037] (3) Take 3 mL of dissolved cellulose solution, add 2 g of ground NaCl particles, and stir evenly. Spread the mixture evenly on a Petri dish about 2mm, pre-gel at 40°C for 1h, then dissolve the solvent and NaCl in the solution with deionized water, the solvent exchange time is 20h; then freeze-dry at -20°C for 1h A porous cellulose paper base material is formed.

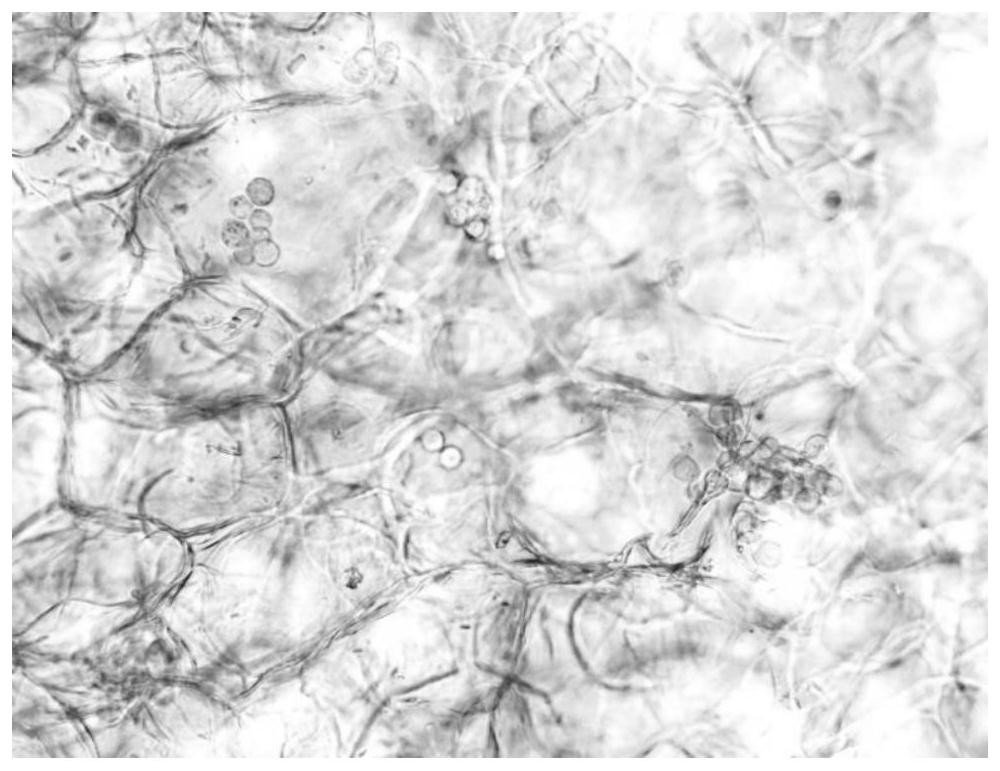

[0038] (5) The prepared cellulose paper-based material was sterilized in an autoclave at 120° C. for 20 minutes, and cut into discs with a diameter of 15 mm. 2 mL of gelati...

Embodiment 2

[0042](1) Weigh 3g of microcrystalline cellulose, add 30mL of N,N-dimethylacetamide (DMAC), stir and activate at 140°C for 45min, and then cool to room temperature. Add 7 g of lithium chloride and 70 mL of DMAC to the cooled cellulose, and heat and stir at 70° C. until the microcrystalline cellulose dissolves.

[0043] (2) Grinding sodium chloride (NaCl) with a mortar, and screening out NaCl particles with a size smaller than 45 μm.

[0044] (3) Take 3 mL of dissolved cellulose solution, add 3 g of ground NaCl particles, and stir evenly. Spread the mixture evenly on a petri dish about 3mm, pre-gel at 20°C for 1.5h, then dissolve the solvent and NaCl in the solution with deionized water, the solvent exchange time is 22h; then freeze-dry to form a porous Cellulose paper base material.

[0045] (5) The prepared cellulose paper-based material was sterilized in an autoclave at 140° C. for 25 minutes, and cut into discs with a diameter of 15 mm. 1 mL of 0.1% gelatin solution was ...

Embodiment 3

[0049] (1) Weigh 3 g of microcrystalline cellulose, add 25 mL of N,N-dimethylacetamide (DMAC), stir and activate at 150° C. for 1 h, and then cool to room temperature. Add 8 g of lithium chloride and 75 mL of DMAC to the cooled cellulose, heat and stir at 80° C. until the microcrystalline cellulose dissolves.

[0050] (2) Grinding sodium chloride (NaCl) with a mortar, and screening out NaCl particles with a size smaller than 45 μm.

[0051] (3) Take 3 mL of dissolved cellulose solution, add 3 g of ground NaCl particles, and stir evenly. Spread the mixture evenly on a Petri dish about 4mm, pre-gel at 60°C for 0.5h, then dissolve the solvent and NaCl in the solution with deionized water, and the solvent exchange time is 24h; then freeze-dry to form a porous Cellulose paper base material.

[0052] (5) Sterilize the prepared cellulose paper-based material in an autoclave at 120° C. for 20 min, cut it into discs with a diameter of 15 mm, add 1.5 mL of gelatin solution with a mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com