A device and method for rotating and centrifuging to extract tiny particles in solution

A rotating centrifugal, tiny particle technology, applied in the field of metal physics research, can solve the problems of difficulty in obtaining a large number of evenly distributed inclusion particles, difficulty in preserving inclusions, and difficulty in efficiently removing impurity particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

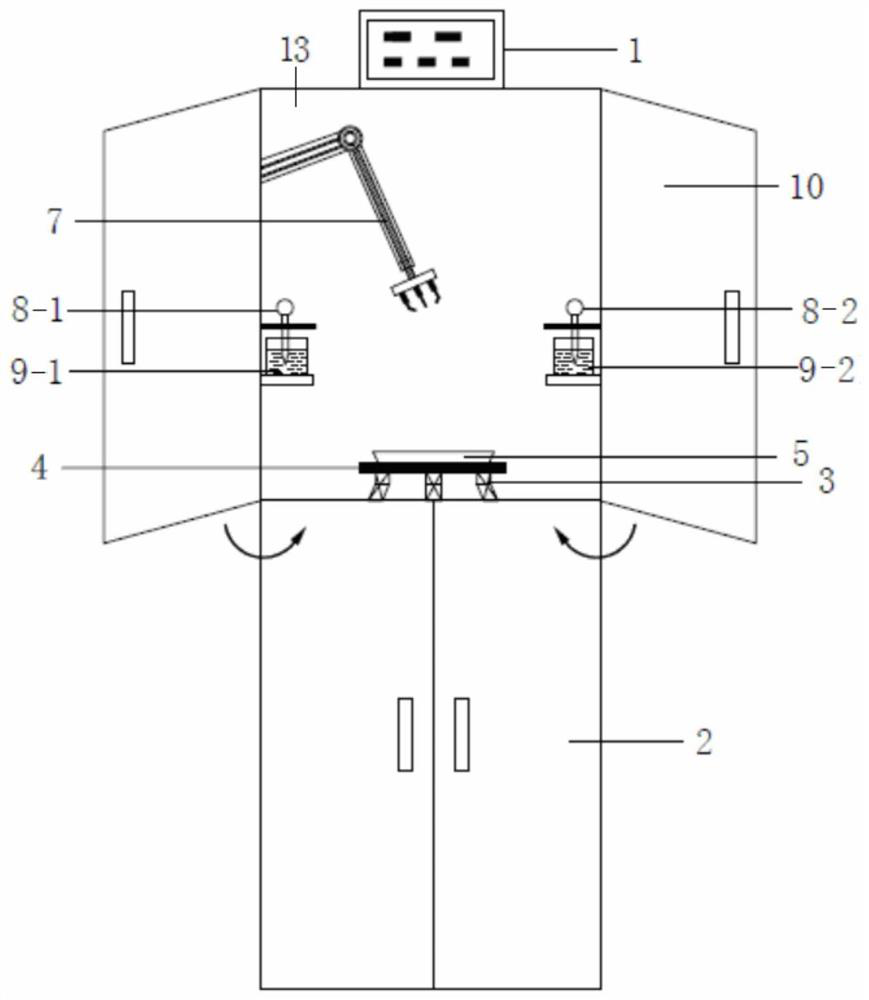

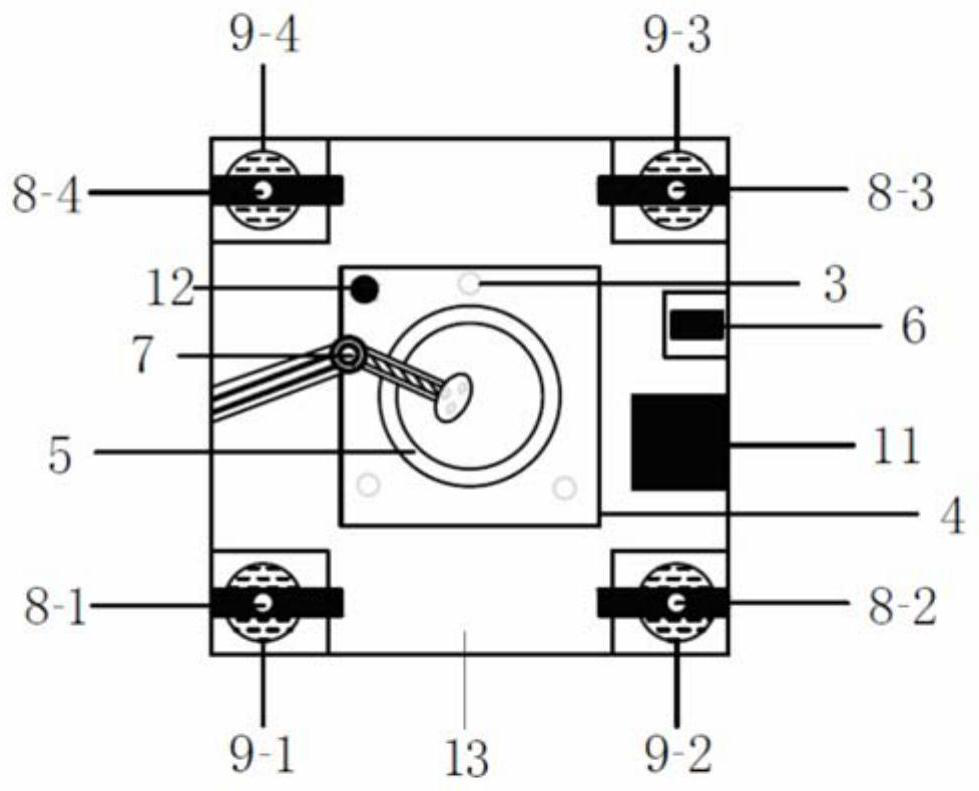

[0045] Such as Figure 1-Figure 2 As shown, a device and method for extracting tiny particles in a solution by rotating and centrifuging in this embodiment extracts non-metallic inclusions in steel. The specific steps are as follows:

[0046] Step 1. Hold the liquid and calibrate the level

[0047] After the steel matrix is eroded by organic liquid electrolysis or acid solution, a solution containing second-phase particles is obtained. The general electrolyte is triethanolamine volume fraction 3-10%, glycerol volume fraction 3-10%, tetramethyl The mass fraction of ammonium chloride is 1~3%, the rest is methanol, the electrolysis time is 6~8h, and the current density is 40~60mA / cm 2 ; The acid used in the acid-soluble method is an aqueous hydrochloric acid solution with a volume ratio of 1:1 diluted with an inorganic solvent, and the dissolution time is about 8 hours. After ultrasonic treatment of the solution in the beaker for 2 to 4 minutes, pour the solution into the wat...

Embodiment 2

[0055] Such as Figure 1-Figure 2As shown, a device and method for extracting tiny particles in a solution by rotating and centrifuging in this embodiment is used to extract carbides in steel. The rotational angular velocity of the dish is 1-2rad / s, and the amplitude is 8mm; in the particle separation process of step 3, the center of rotation is guaranteed to change at a constant speed, and its trajectory is on a circle with the lowest point of the watch dish as the center and a diameter range of 5-7mm. , the movement speed of the rotation center point is 0.25mm / s, and then superimposed the circular movement with a speed of 1~2rad / s, the maximum amplitude is 8mm, and this movement mode lasts for 200s.

Embodiment 3

[0057] Such as Figure 1-Figure 2 As shown, a device and method for extracting tiny particles in a solution by rotating and centrifuging in this embodiment extracts micron-sized and nano-sized pure copper particles. During the process, the mechanical arm 7 is no longer needed to send the electromagnet 6 to the top of the watch glass 5 for magnetic particle adsorption. The watch glass has a rotational angular velocity of 2-3 rad / s and an amplitude of 6 mm. During the particle separation process in Step 3, ensure that the center of rotation changes at a constant speed, and its trajectory is on a circle with the lowest point of the watch glass as the center and a diameter range of 7 to 10 mm. The movement speed of the center of rotation is 0.3 mm / s. Then superimpose the circular motion with the rotational speed of 2-3 rad / s, the maximum amplitude is 6 mm, and this motion mode lasts for 200 s.

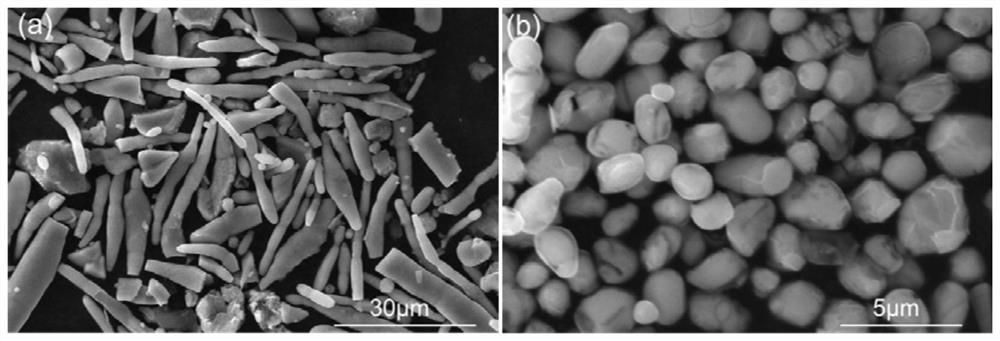

[0058] Such as image 3 As shown, from the three-dimensional appearance of non-metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com