High temperature resistant interdigitated electrode protected by glass glaze outer surface, its preparation method and application

A technology of interdigitated electrodes and glass glaze, which is applied in the field of interdigitated electrodes for outer surface protection and its preparation, which can solve the problems of decreased sensitivity and detection performance of interdigitated electrodes, decreased performance of interdigitated electrodes, and easy oxidation of metal circuits, etc., to achieve detection The effect of fast speed, high hardness and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

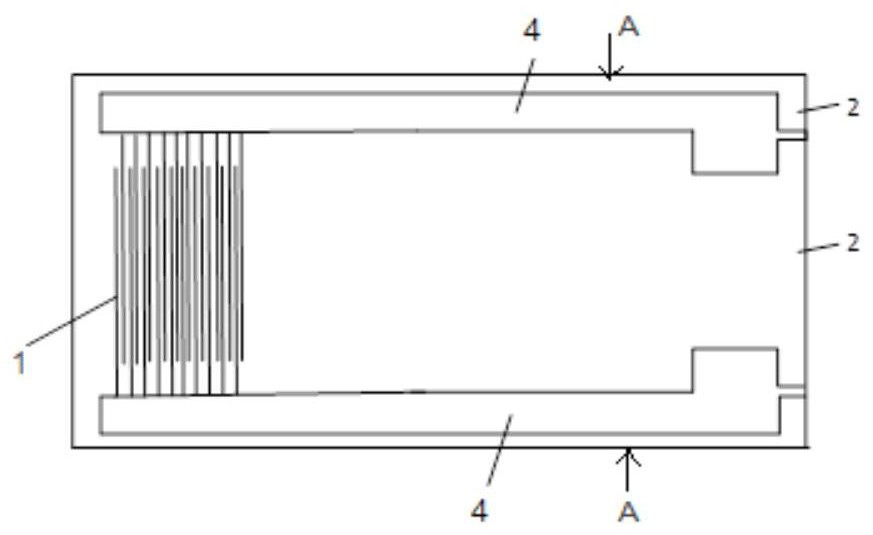

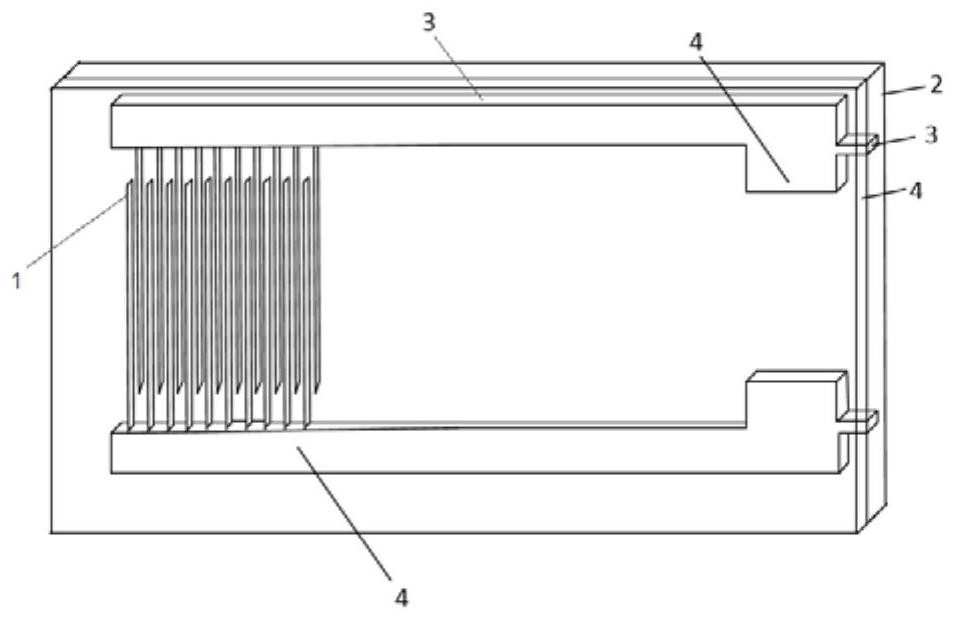

[0037] Fabrication of Interdigitated Electrodes Containing Glass Glaze on Aluminum Oxide Surface

[0038] (1) Magnetron sputtering Ti / Pt / Au on the surface of alumina ceramic substrate 2, each layer

[0039] (2) The photoresist is suspended on the surface, developed and exposed under a photolithography machine, and an interdigitated electrode pattern is formed.

[0040] (3) After developing, develop in 5 mol / L potassium carbonate solution to form graphics.

[0041] (4) Electroplate a gold layer of about 2 μm on the exposed metal surface. The formula of the gold plating solution is gold citrate solution, 4 g / L in terms of Au, the pH value is between 4.5-6.5, the temperature is between 45-55 °C, and the current density 1.0-1.5ASF, electrodeposition time is 5min.

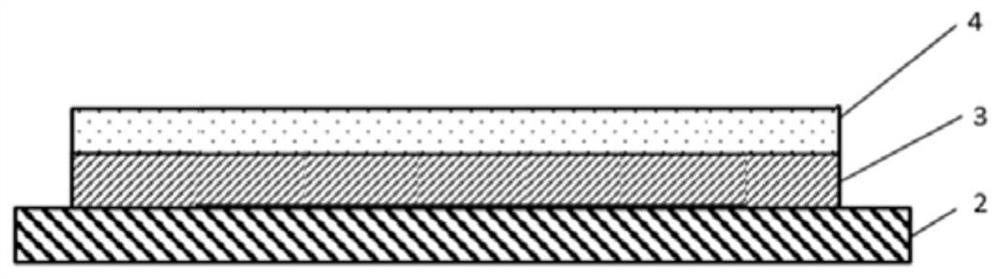

[0042] (5) Remove photoresist in 2 mol / L potassium hydroxide solution, etch and remove excess gold layer and titanium layer after surface cleaning, to form electrode layer 3 .

[0043] (6) The entire panel is spray...

Embodiment 2

[0047] Fabrication of Interdigitated Electrodes Containing Glass Glaze on Silicon-Based Surfaces

[0048] (1) Magnetron sputtering SiO on the surface of silicon substrate 2 2 / Ti / Pt / Au, per layer

[0049] (2) The photoresist is suspended on the surface, developed and exposed under a photolithography machine, and an interdigitated electrode pattern is formed.

[0050] (3) After developing, develop in 5 mol / L potassium carbonate solution to form graphics.

[0051] (4) Electroplate a gold layer of 1 μm on the bare metal surface, and the formula of the gold plating solution is KAu(CN) 2 The solution is 5g / L in terms of Au, the pH value is between 4.5-6.5, the temperature is between 45-55°C, the current density is 1.0-1.5ASF, and the electrodeposition time is 5min.

[0052] (5) The photoresist is removed in a 5 mol / L potassium hydroxide solution, and after the surface is cleaned, the redundant gold layer and titanium layer are etched away to form the electrode layer 3 .

[00...

Embodiment 3

[0057] Fabrication of Interdigitated Electrodes Containing Glass Glaze on Aluminum Nitride Surfaces

[0058] (1) Magnetron sputtering of Ti-Wu / Pt / Au on the surface of the aluminum nitride ceramic substrate 2, wherein the mass ratio of titanium and tungsten in the titanium-tungsten alloy is 70%:30%.

[0059] (2) The photoresist is suspended on the surface, developed and exposed under a photolithography machine, and an interdigitated electrode pattern is formed.

[0060] (3) After developing, develop in 5 mol / L potassium carbonate solution to form graphics.

[0061] (4) A gold layer of 3 μm is electroplated on the bare metal surface. The formula of the gold plating solution is gold citrate solution, which is 3 g / L in terms of Au, the pH value is between 4.5-6.5, the temperature is between 45-55 °C, and the current density is 1.0 -1.5ASF, electrodeposition time is 5min.

[0062] (5) The photoresist is removed in 4 mol / L potassium hydroxide solution, the surface is cleaned and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com