Three-dimensional nano composite electrode material for electrochemical energy storage and preparation method thereof

A three-dimensional nano, composite electrode technology, used in electrode manufacturing, battery electrodes, electrochemical generators, etc., to achieve the effects of high assembly density, good electrical conductivity, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

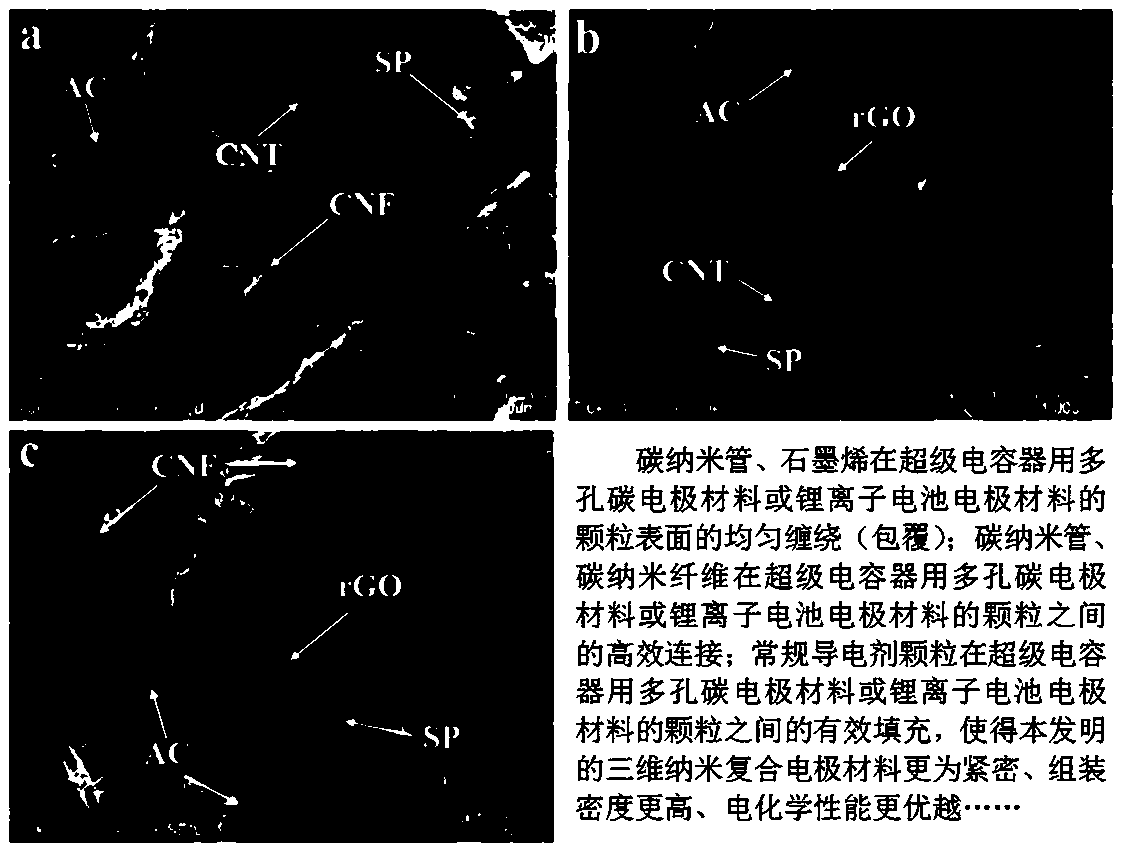

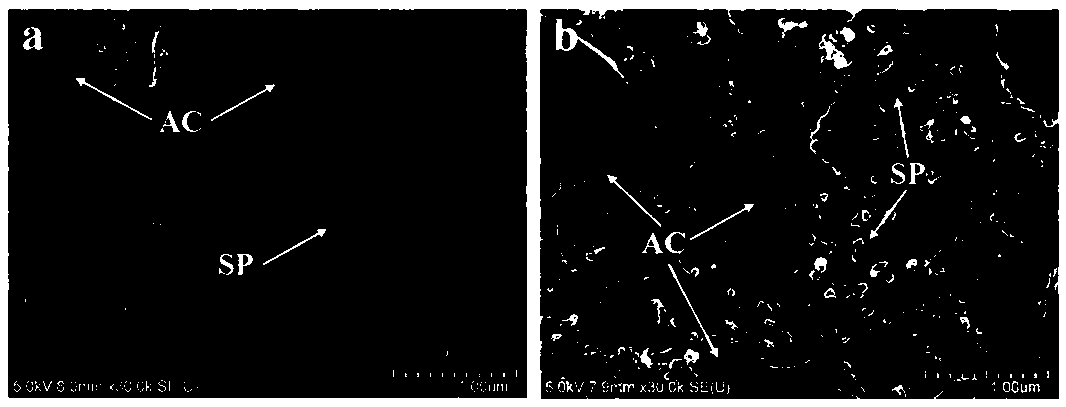

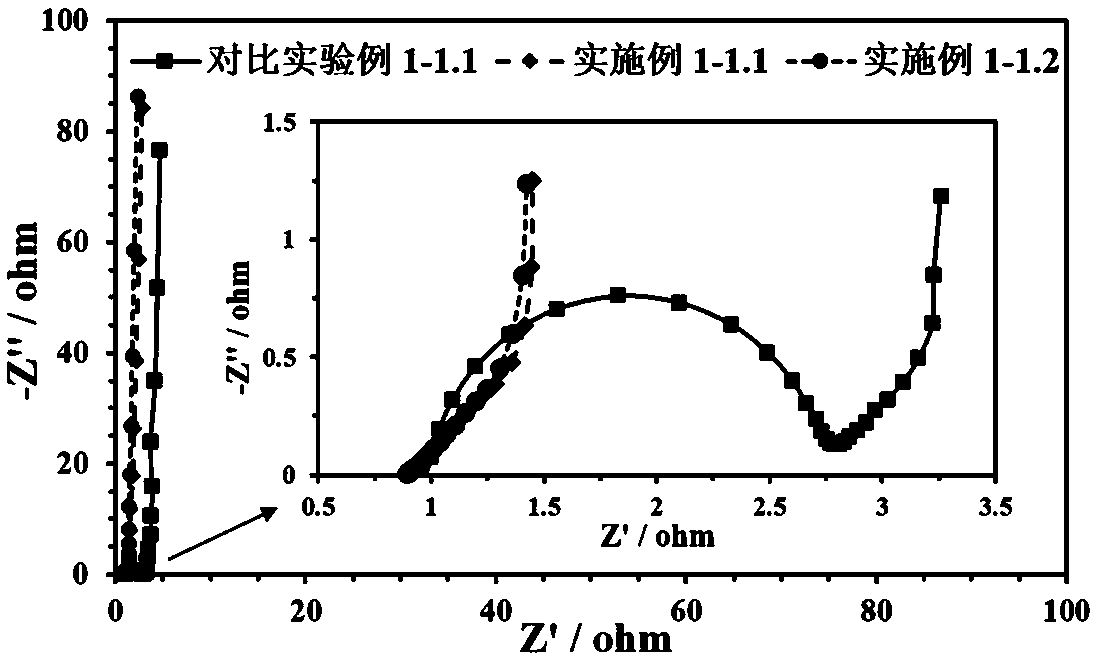

[0041] Embodiment 1, the preparation and testing of the high-performance new three-dimensional nano-composite electrode for the supercapacitor of the present invention:

[0042] 1. Preparation of high-performance new three-dimensional nanocomposite electrodes for supercapacitors of the present invention

[0043] 1.1 Preparation of three-dimensional nanocomposite electrodes of AC / CNT / CNF / SP / SBR / CMC (90 / 3.125 / 0.625 / 1.25 / 3 / 2)

[0044] A. Preparation of mixed solution of sodium carboxymethylcellulose (CMC) and styrene-butadiene rubber (SBR)

[0045] Accurately weigh 1 g of sodium carboxymethylcellulose (CMC) solid powder and add it to a 100 ml beaker, then weigh 99 g of ultrapure water and add it to the beaker, put a magnet with a length of 2 cm, and use a plastic film and The mouth of the beaker was sealed with a rubber ring, and the beaker was placed on a magnetic stirrer at a set speed of 100 r / min, and stirred at room temperature for 12 hours to obtain a CMC aqueous solution ...

Embodiment 2

[0100] Embodiment 2, the preparation and testing of high-performance new three-dimensional nano-composite electrodes for lithium-ion batteries of the present invention:

[0101] 1. Preparation of high-performance new three-dimensional nanocomposite electrodes for lithium-ion batteries

[0102] 1.1 Preparation of three-dimensional nanocomposite electrodes (LFP / rGO / CNT / SP / KS6 / PVDF=90 / 1 / 1 / 3 / 1 / 4) coated with reduced graphene oxide / carbon nanotubes coated lithium iron phosphate (aqueous phase)

[0103] A, the preparation of graphite oxide

[0104] Graphite oxide was prepared according to the method in step B a) of 1.2 in Example 1.

[0105] B. Preparation of LFP / rGO (90 / 1) composites:

[0106] In a 250 mL beaker, add 100 mL of ultrapure water and 10 mL of 80 wt% water and hydrazine solution, add the graphite oxide prepared in step A with a mass ratio of 1 wt% (0.2 g) to the above solution, After ultrasonic dispersion for 10 min, LFP material with a mass ratio of 90 wt% (18 g) wa...

Embodiment 3

[0155] The proportions of the components in the three-dimensional nanocomposite electrode material are: 0.005% carbon nanotube (CNT), 0.005% carbon nanofiber (CNF) or graphene (Graphene), 1% carbon black, and styrene-butadiene rubber. (SBR) binder 1%, activated carbon powder 97.99%. The supercapacitor of the present invention was prepared according to the process used in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com