Advanced customized scar-removing jet ink and mask thereof

An inkjet ink and scar technology, which is applied in the field of high-definition scar removal inkjet ink and its mask, can solve the problems of unpublished printing mask printing effect and technical parameters, skin care lotion can not be effectively used in inkjet printers, etc., to achieve The effect of high practical craft value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Scar Removal Formula

[0055] Recipe 1:

[0056] Solvent: 1000 parts of pentylene glycol, 2000 parts of ethylhexylglycerin, 3000 parts of laureth, 4000 parts of amidopropyl betaine;

[0057] Active substances: 0.1 part of soluble proteoglycan, 0.3 part of baicalin, 0.3 part of Scutellaria baicalensis root extract, 0.3 part of retinol and its derivatives;

[0058] The stirring rate was 50 rpm, and the preparation time was 2 h.

[0059] Recipe 2:

[0060] Solvent: 1 part peanut alcohol;

[0061] Active substances: 20 parts of Scutellaria baicalensis root extract, 10 parts of aloe vera leaf extract, 10 parts of cucumber fruit extract, 10 parts of lavender extract;

[0062] The stirring rate is 300 rev / min, and the preparation time is 0.8h.

[0063] Recipe 3:

[0064] Solvent: 1000 parts of hexyl acetate palmitate, 3000 parts of neopentyl glycol dicaprate, 1000 parts of glycine surfactant;

[0065] Active substances: 0.2 part of tocopherol and its derivati...

Embodiment 2

[0080] Embodiment two: inkjet ink preparation method

[0081] (1) If the ink-jet ink formulations of Example 1 contain low-polarity grease and surfactant, this is first mixed into the first phase, and stirred at room temperature until uniformly mixed;

[0082] (2) Mix the other components according to the ratio to form the second phase, and stir at room temperature until they are evenly mixed;

[0083] (3) Mix the first phase and the second phase, and stir at room temperature until they are evenly mixed.

[0084] Stir evenly according to the speed and time of the above-mentioned embodiments, the ink obtained in this way is uniform, transparent and stable, and its shelf life can reach 8-10 months. About 50ml of ink can be prepared within 1-5min for timely use.

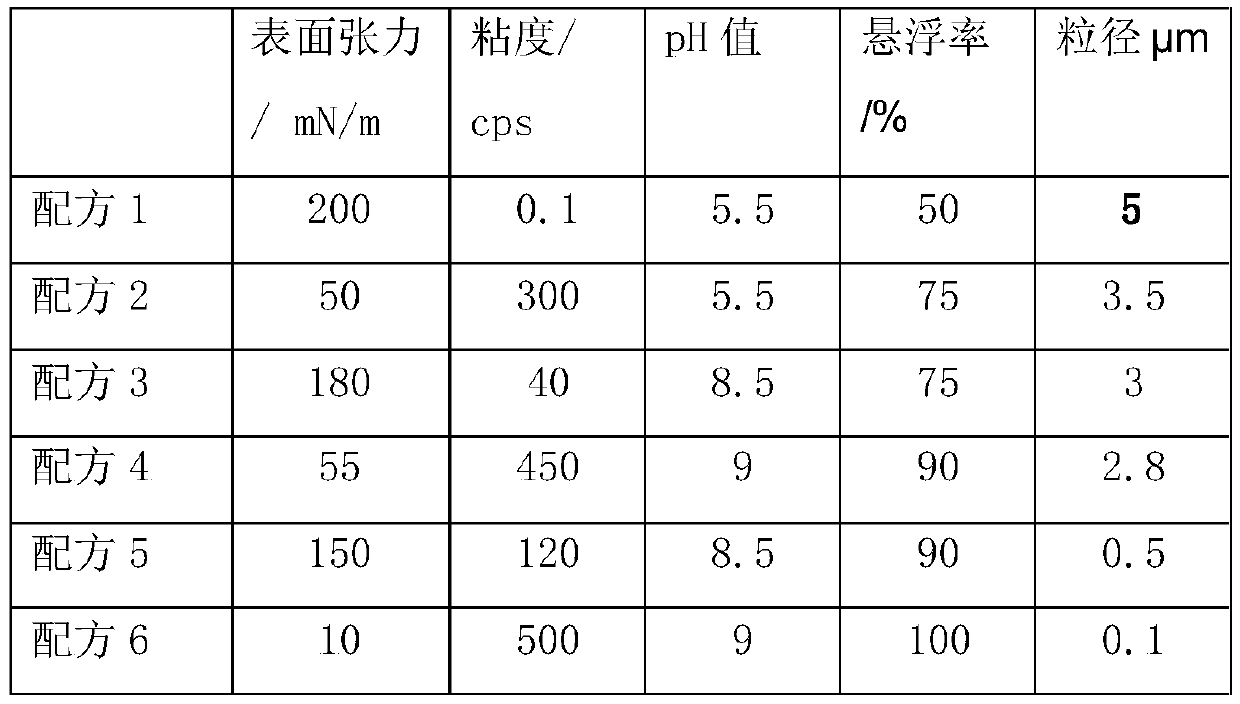

[0085] The following table is the parameter table of the ink prepared according to the above-mentioned formula and preparation method:

[0086]

Embodiment 3

[0087] Embodiment 3: An online customized scar removal mask

[0088] An online customized scar removal mask, the scar removal inkjet ink is sprayed on the film cloth substrate through an inkjet printer. The inkjet printer can choose commercially available heat-sensitive nozzles or piezoelectric nozzles, such as Epson piezoelectric nozzles, which can be used for both heat-sensitive active materials and non-heat-sensitive active materials. The base material of the film cloth is viscose nonwoven fabric, spunbonded nonwoven fabric, plant fiber nonwoven fabric (tencel, fruit fiber, superfine, red toon, eucalyptus, cotton, bamboo fiber), silk nonwoven fabric , polyester, nylon, blended, biological fiber film cloth, dehydrated mud film, dehydrated and rehydratable gel film or modified film cloth, and the modified film cloth is frozen with moisturizing and thickening ingredients Dry mask, or dry mask, and the base material of the modified film cloth is one or more blends of non-woven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com