Catalyst for phosgene synthesis, and preparation method and application thereof

A technology for catalyst and phosgene, which is applied in the field of catalyst for preparing phosgene and its preparation, can solve the problems of poor thermal conductivity, low quality of phosgene and by-product steam, and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

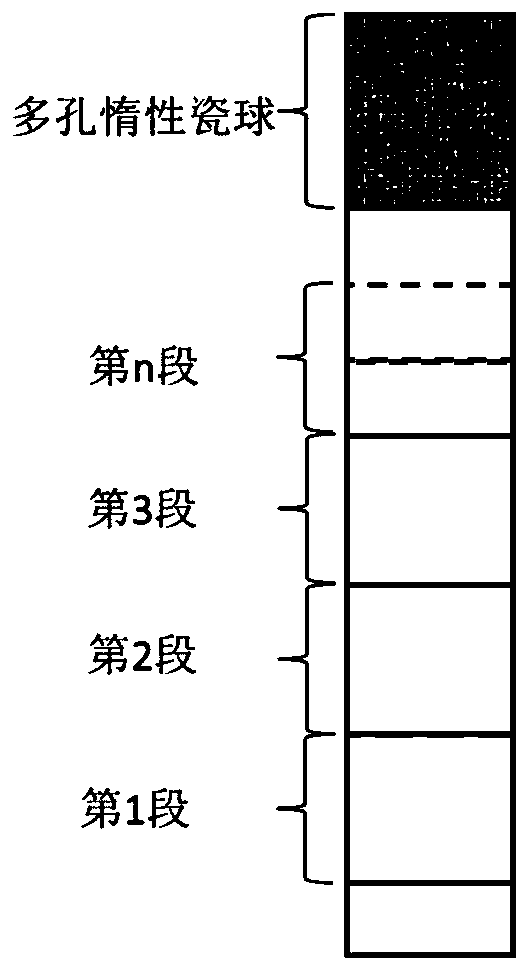

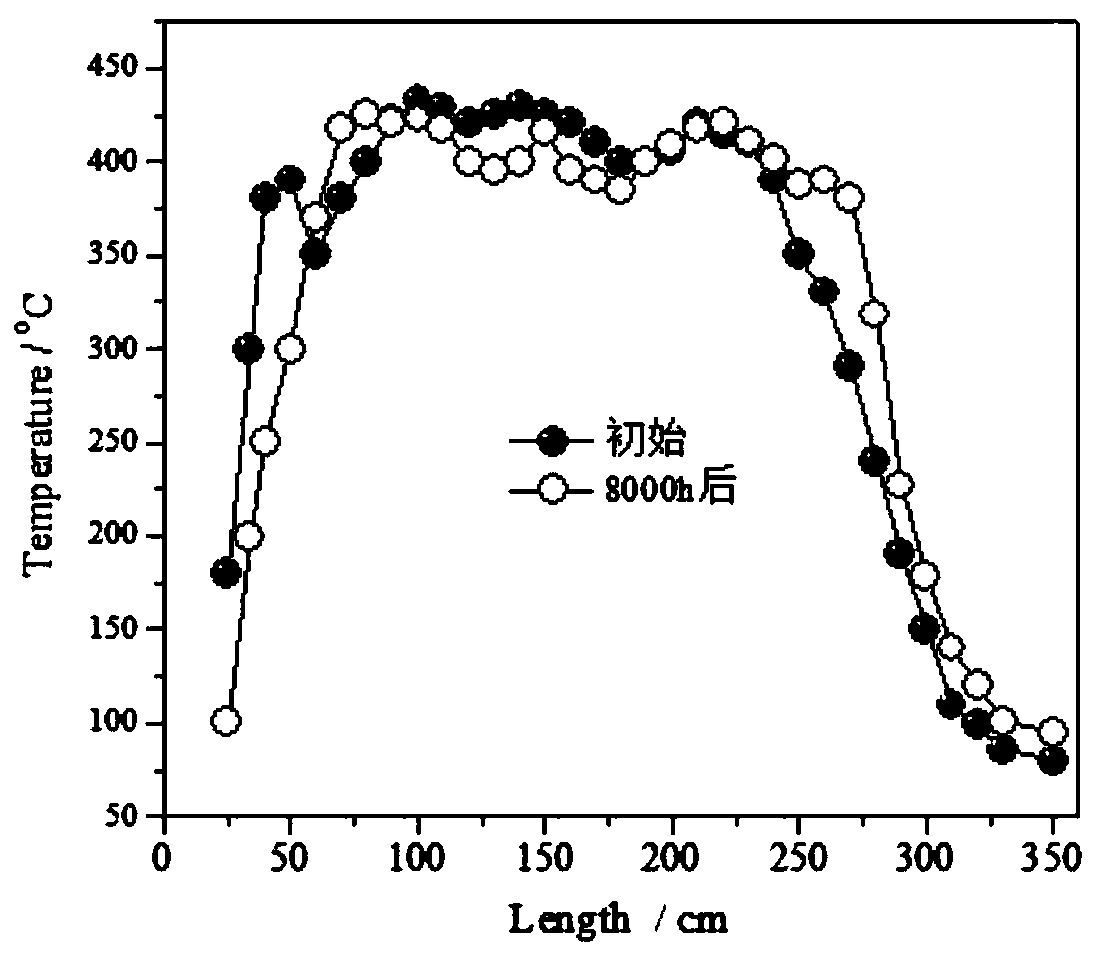

Method used

Image

Examples

preparation example Construction

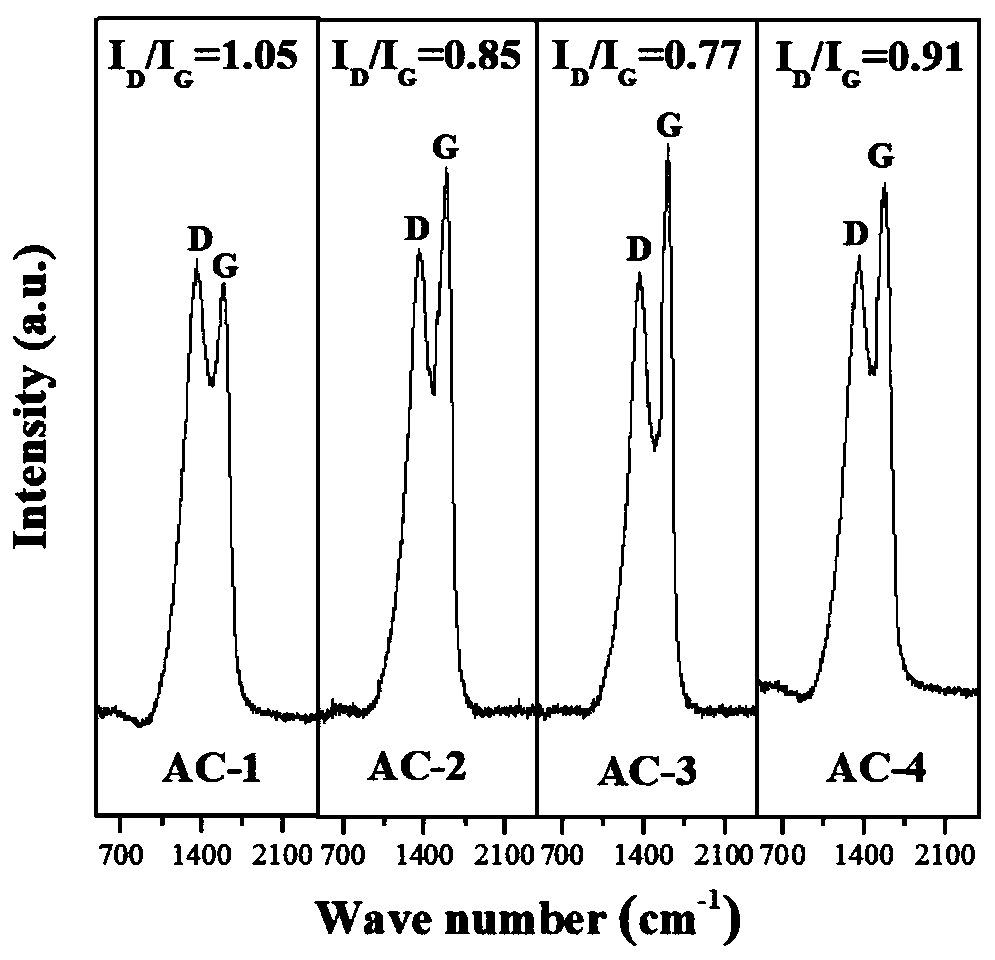

[0099] Table 1. Preparation conditions and physical property data of different activated carbons

[0100]

[0101] Other main sources of raw materials used in the embodiments of the present invention or comparative examples:

[0102] Bismuth nitrate was purchased from Shenyang Xinguang Chemical Factory;

[0103] Polyvinyl alcohol and pentylene glycol were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.;

[0104] Hydrochloric acid and nitric acid were purchased from Xilong Chemical Co., Ltd.;

[0105] Unless otherwise specified, other raw materials are also commercially available raw materials.

Embodiment 1

[0107] Catalyst 1# prepared for phosgene synthesis,

[0108] (1) Weigh 100g AC-2 activated carbon, 5g carbon nanotubes, disperse in 500mL concentration of 0.4mol / L bismuth nitrate nitric acid solution (wherein 68% nitric acid consumption is 40.1g), heat, stir and reflux at 85°C for 5h ;

[0109] Suction filter the above slurry, wash with deionized water until the filtrate is neutral, collect the upper filter cake, and dry at 120°C for 2 hours to obtain a mixed powder of activated carbon and carbon nanotubes;

[0110] (2) In the mixed powder of above-mentioned active carbon and carbon nanotube of 105g, add the polyvinyl alcohol aqueous solution of 10.4g concentration 10wt% molecular weight successively and be the polyvinyl alcohol aqueous solution of 50000, 2.08g concentration 2.5wt%, pH is the hydrochloric acid solution of glutaraldehyde of 1.23 , knead into a plastic embryo body, and extrude to obtain a strip with a diameter of 3 mm and a length of 3 to 6 mm;

[0111] The a...

Embodiment 2

[0116] Catalyst 2# was prepared with reference to Example 1, with the difference that AC-3 activated carbon was used as a raw material, and the obtained strip was calcined at 750° C. for 5 h in an argon atmosphere to obtain a catalyst.

[0117] In catalyst 2#, the mass ratio of carbon nanotubes to activated carbon is 0.05:1, and the catalyst also contains about 0.6wt% polyvinyl alcohol and residual carbon after high-temperature roasting of glutaraldehyde. The thermal conductivity test was carried out on catalyst 2#, and its thermal conductivity at room temperature was found to be 3.04W·m -1 ·K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com