A kind of preparation method of s-(carboxymethyl)-cysteine

A technology of cysteine and carboxymethyl, which is applied in the field of preparation of S-cysteine, can solve the problems of reduced purity of the final product, safety problems, and low efficiency, and achieve the goal of increasing product yield and reducing drying The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

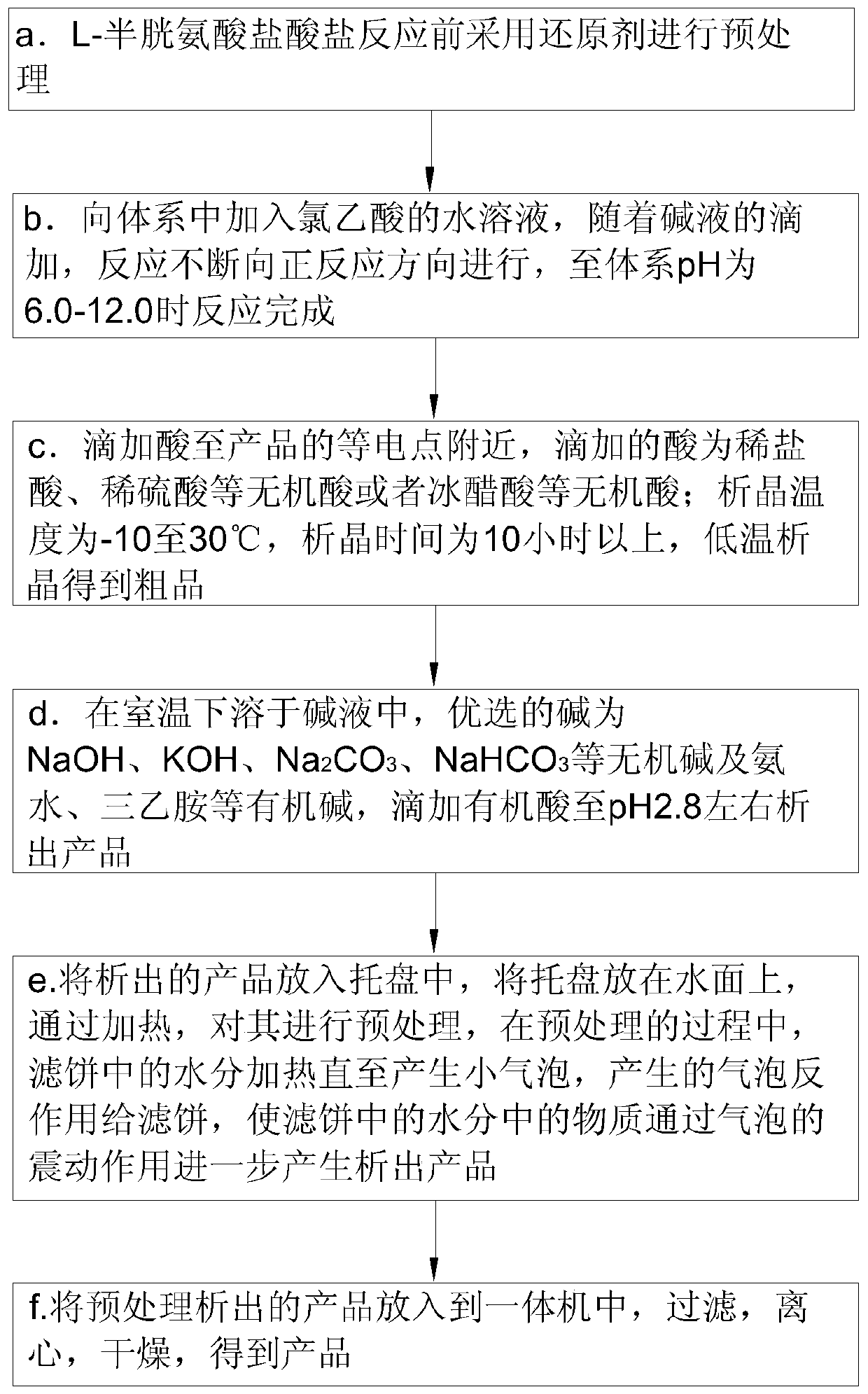

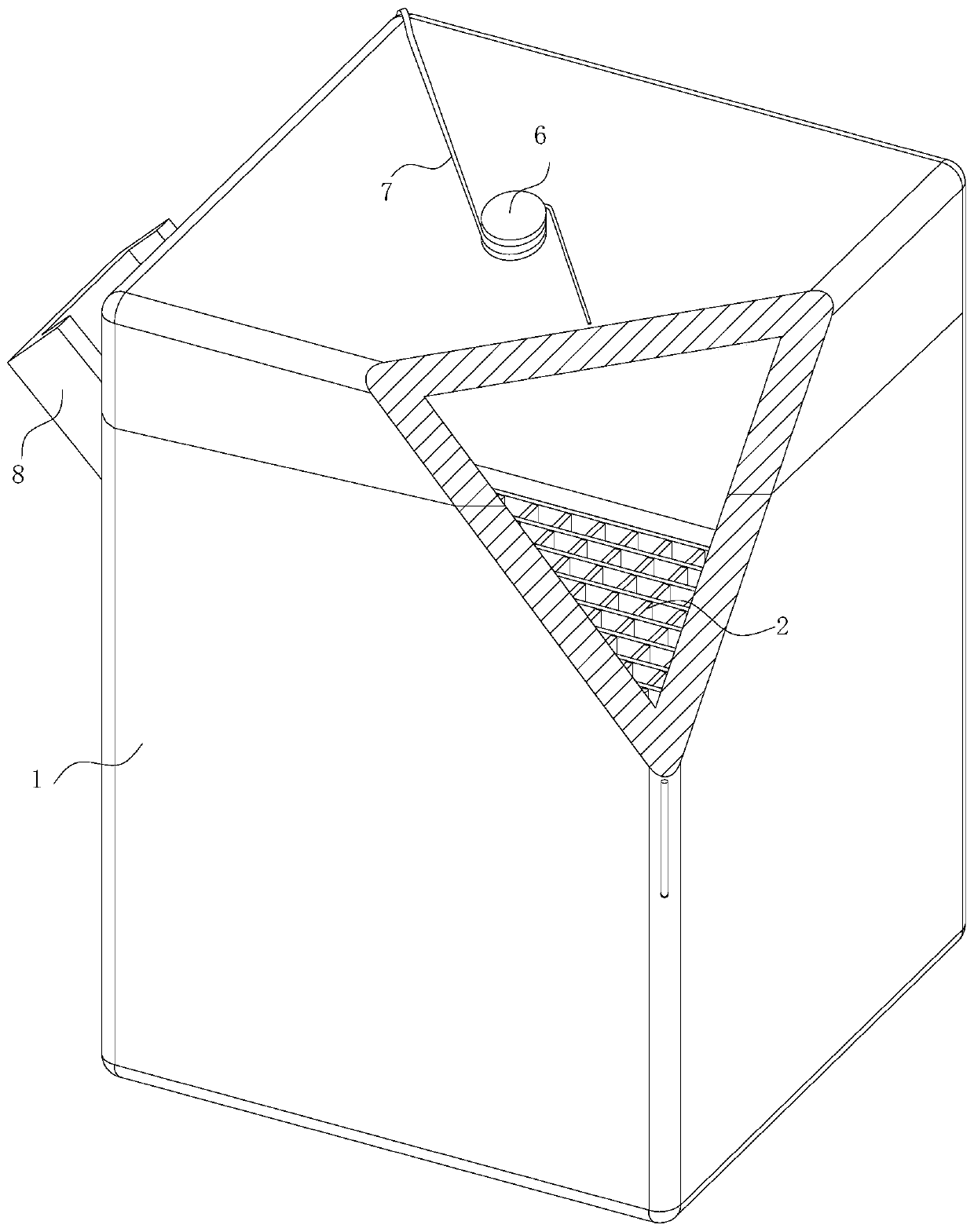

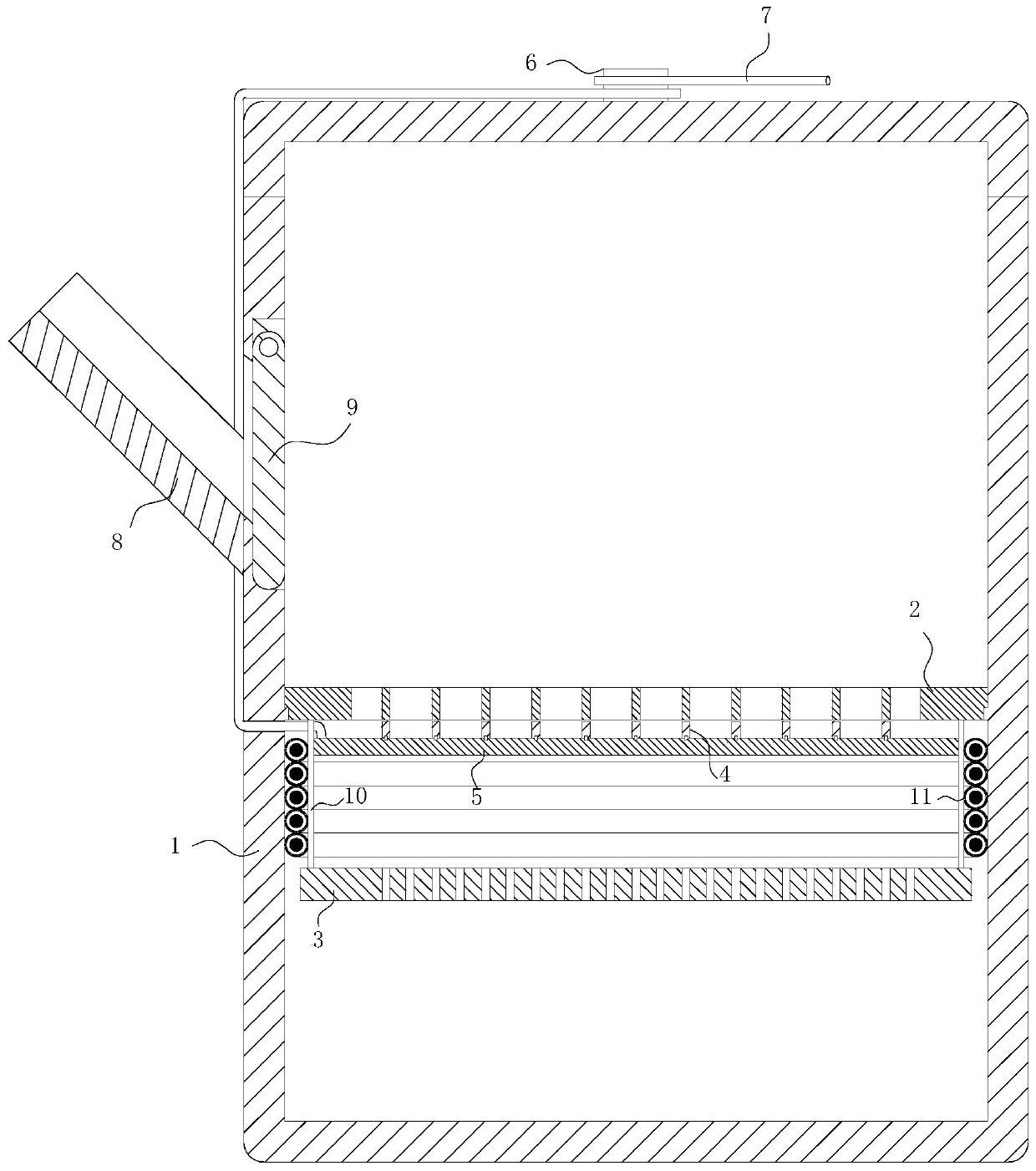

[0030] Such as Figure 1-6 Shown, the preparation method of a kind of S-(carboxymethyl)-cysteine of the present invention comprises the steps:

[0031] a. Before the reaction of L-cysteine hydrochloride, a reducing agent is used for pretreatment, and the reducing agent is iron powder;

[0032] b. Add the aqueous solution of chloroacetic acid in the system, along with the dropwise addition of lye, the reaction continues to the positive reaction direction, and the reaction is completed when the pH of the system is 6.0-12.0;

[0033] c. Add acid dropwise to near the isoelectric point of the product. The acid added dropwise is dilute hydrochloric acid, dilute sulfuric acid or glacial acetic acid; the crystallization temperature is -10 to 30°C, the crystallization time is more than 10 hours, and the crude product is obtained by low temperature crystallization ;

[0034] d. Soluble in lye at room temperature, the alkali is NaOH, KOH, Na 2 CO 3 , NaHCO3, ammonia water or trie...

Embodiment 1

[0042] Add 100.0g of L-cysteine hydrochloride mixture (L-cysteine hydrochloride content 50.2%, L-cystine content 49.0%) and 500mL purified water into 1 L reaction kettle, open at room temperature Stir, add 30.0g of iron powder, raise the temperature to 60°C, react for 30min after reaching the temperature, and then lower the temperature. When the temperature of the reactor reaches 30-40°C, add 66.4g of chloroacetic acid to the reactor and start to add sodium hydroxide solution dropwise. The reaction temperature does not exceed 60°C. When the monitored pH is 7.0-8.0, stop adding the sodium hydroxide solution dropwise, and keep the temperature at 60°C for 30min. After cooling down to room temperature, dilute sulfuric acid was added dropwise to control the temperature of the reaction solution below 30°C. When the pH of the system is about 2.5-3.0, the end point is reached, the temperature is lowered to -5 to 10°C and kept for 16 hours, the filter cake is rinsed with 30g of wa...

Embodiment 2

[0045] Add 100.0g of L-cysteine hydrochloride monohydrate (L-cysteine hydrochloride content 99.5%) and 300mL of purified water into a 1 L reaction kettle, start stirring, dissolve at room temperature, then add Iron powder 5.0g, heat up to 60°C, react for 30 minutes after reaching the temperature, then lower the temperature, when the temperature of the reactor reaches 30-40°C, add 56.5g of chloroacetic acid to the reactor and start adding sodium bicarbonate solution dropwise to control the reaction temperature. over 60°C. When the monitored pH is 7.0-8.0, stop adding the sodium bicarbonate solution dropwise, and keep the temperature at 60°C for 30min. When the temperature is lowered to 15-30°C, dilute sulfuric acid is added dropwise to control the temperature of the reaction solution below 30°C. When the pH of the system is about 2.5-3.0, the end point is reached, the temperature is lowered to -5 to 0°C and kept for 12 hours, the filter cake is rinsed with 30g of water, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com