Surface oxygen vacancy defect modified bismuth tungstate photocatalyst, and preparation method and applications thereof

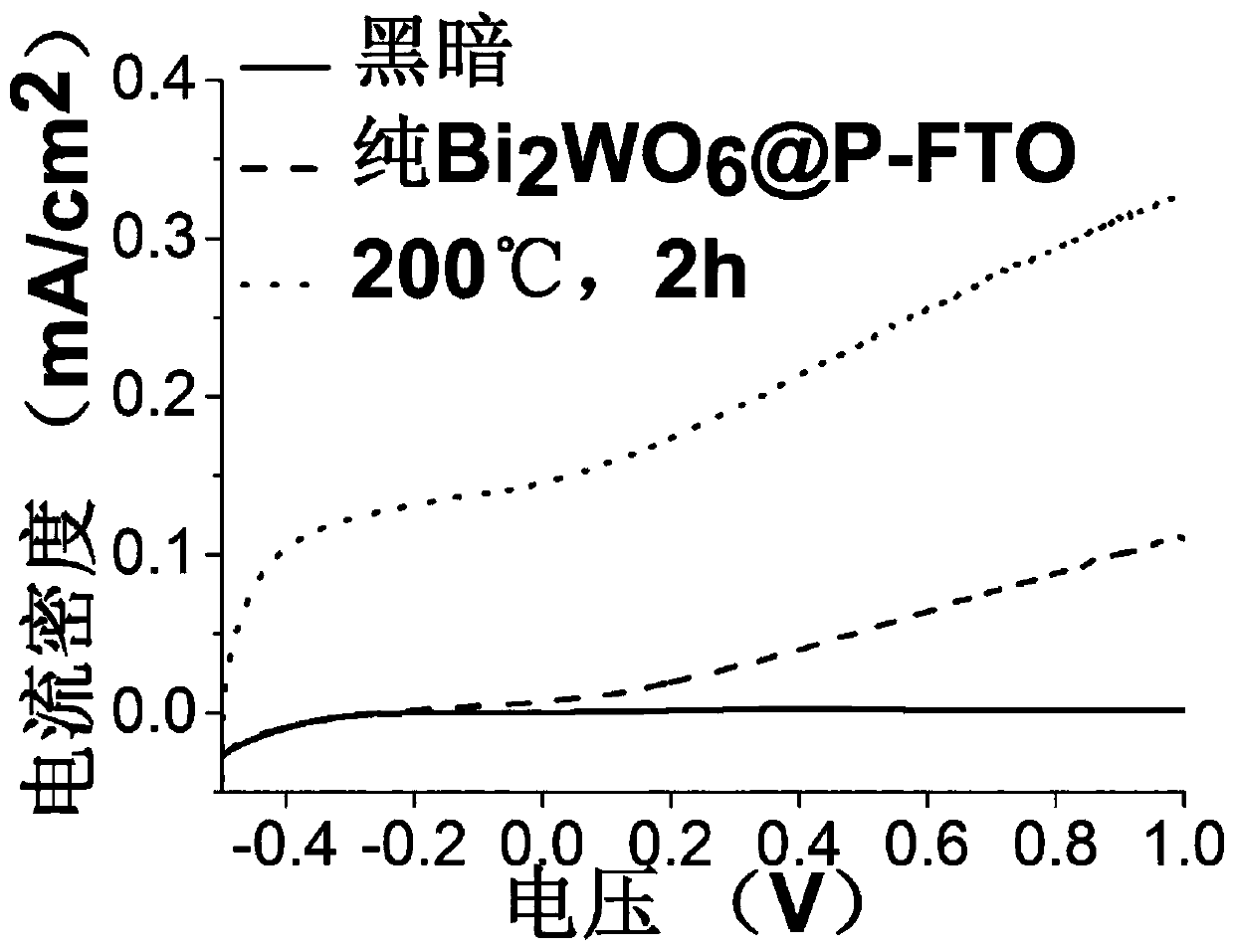

A vacancy defect, photocatalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as unfavorable photocatalytic reactions, small surface area and specific surface area , to achieve the effect of simple preparation process, increased amount, and widened visible light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Dissolve 1mmol of sodium tungstate dihydrate in 7.5ml of deionized water; dissolve 1mmol of bismuth nitrate pentahydrate in 7.5ml of dilute nitric acid solution with a pH value equal to 5; both are ultrasonicated until clarified to obtain tungsten sodium bismuth nitrate precursor and bismuth nitrate precursor.

[0032] 2. The clean flat FTO conductive glass is tilted and placed in a 25ml high-temperature reaction kettle, and the bismuth nitrate precursor solution and the sodium tungstate precursor solution are mixed to obtain the bismuth tungstate precursor solution in the state of milky white turbid liquid, and immediately transferred to the high-temperature reaction kettle middle. Hydrothermal reaction at 100°C for 3 hours, rinse the sample with deionized water after the reaction, remove excess reaction residue, dry under nitrogen, then transfer to a muffle furnace for dry crystallization, and grow tungsten on a flat FTO conductive glass bismuth film.

[0033] 3....

Embodiment 2

[0042] 1. Dissolve 0.5mmol of sodium tungstate dihydrate in 7.5ml of deionized water; dissolve 0.2mmol of bismuth nitrate pentahydrate in 7.5ml of dilute nitric acid solution with a pH value equal to 6; Obtain sodium tungstate precursor solution and bismuth nitrate precursor solution.

[0043] 2. The clean flat fluorine-doped tin oxide is placed in a 25ml high-temperature reaction kettle, and the bismuth nitrate precursor solution and sodium tungstate precursor solution are mixed to obtain a milky white turbid liquid bismuth tungstate precursor solution, and immediately transfer to high temperature in the reactor. Hydrothermal reaction at 150°C for 3 hours, rinse the sample with deionized water after the reaction, remove excess reaction residue, dry under nitrogen, then transfer to a muffle furnace for dry crystallization, and grow tungsten on a flat FTO conductive glass bismuth film.

[0044] 3. The bismuth tungstate thin film is kept in a muffle furnace at 600°C for 2 hour...

Embodiment 3

[0047] 1. Dissolve 0.3mmol of sodium tungstate dihydrate in 7.5ml of deionized water; dissolve 0.2mmol of bismuth nitrate pentahydrate in 7.5ml of dilute nitric acid solution with a pH value equal to 3; Obtain sodium tungstate precursor solution and bismuth nitrate precursor solution.

[0048] 2. The clean flat fluorine-doped tin oxide is placed in a 25ml high-temperature reaction kettle, and the bismuth nitrate precursor solution and sodium tungstate precursor solution are mixed to obtain a milky white turbid liquid bismuth tungstate precursor solution, and immediately transfer to high temperature in the reactor. Hydrothermal reaction at 180°C for 3 hours, rinse the sample with deionized water after the reaction, remove excess reaction residue, dry under nitrogen, then transfer to a muffle furnace for dry crystallization, and grow tungsten on a flat FTO conductive glass bismuth film.

[0049] 3. The bismuth tungstate thin film is kept in a muffle furnace at 450°C for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com