A high-throughput biomimetic nanofiltration membrane based on layered graphite phase carbon nitride nanosheets and its preparation method

A phase carbon nitride and layered graphite technology, applied in the field of nanofiltration membranes, can solve the problems of inability to precisely control the surface structure, large particle size of polydopamine particles, damage to the surface morphology of the substrate, etc. Excellent property and the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-throughput bionic nanofiltration membrane based on layered graphitic carbon nitride nanosheets, the preparation method thereof comprises the following steps:

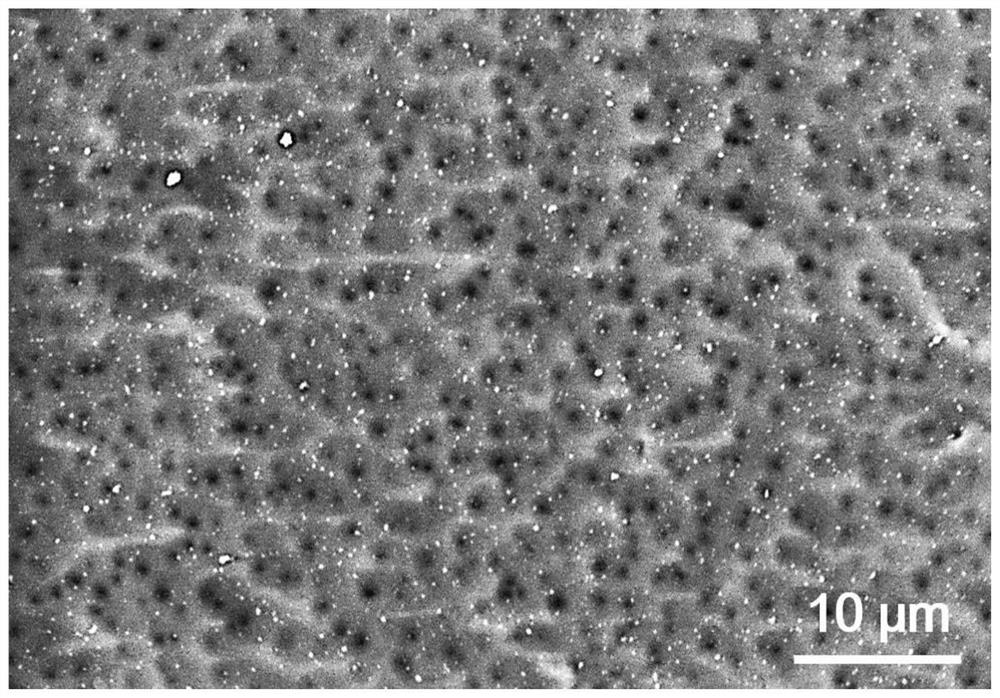

[0037] 1) Immerse the polyacrylonitrile ultrafiltration membrane (12cm×12cm) in 250mL of sodium hydroxide solution with a concentration of 2mol / L for 20h hydrolysis (the SEM image of the polyacrylonitrile ultrafiltration membrane after hydrolysis is as follows: figure 1 shown), then soaked in deionized water for protonation to obtain a pretreated polyacrylonitrile ultrafiltration membrane;

[0038] 2) Add 5 g of melamine to the crucible and place it in a muffle furnace, heat it up to 600 °C at a heating rate of 5 °C / min, calcinate for 2 hours, and then grind the calcined product into powder and put it into an oxygen plasma cleaning machine. Lower treatment for 30min to obtain carbon nitride powder;

[0039] 3) Disperse 0.1 g of carbon nitride powder in 100 mL of deionized water, then ultrasonically peel f...

Embodiment 2

[0045] A high-throughput bionic nanofiltration membrane based on layered graphitic carbon nitride nanosheets, the preparation method thereof comprises the following steps:

[0046] 1) Soak the polyacrylonitrile ultrafiltration membrane (12cm×12cm) in 250mL sodium hydroxide solution with a concentration of 1.5mol / L for 25h hydrolysis, and then soak in deionized water for protonation to obtain pretreated polypropylene Nitrile ultrafiltration membrane;

[0047] 2) Add 5 g of melamine to the crucible and place it in a muffle furnace, heat it up to 550 °C at a heating rate of 4 °C / min, calcinate for 3 hours, and then grind the calcined product into powder and put it in an oxygen plasma cleaning machine. Lower treatment for 20min to obtain carbon nitride powder;

[0048] 3) Disperse 0.1 g of carbon nitride powder in 100 mL of deionized water, then ultrasonically peel for 18 h, and then centrifuge at 4000 rpm for 15 min to remove the lower layer precipitate to obtain a layered graph...

Embodiment 3

[0053] A high-throughput bionic nanofiltration membrane based on layered graphitic carbon nitride nanosheets, the preparation method thereof comprises the following steps:

[0054] 1) Soak the polyacrylonitrile ultrafiltration membrane (12cm×12cm) in 250mL sodium hydroxide solution with a concentration of 1mol / L for 28h hydrolysis, and then soak in deionized water for protonation to obtain pretreated polyacrylonitrile Ultrafiltration membrane;

[0055] 2) Add 5g of melamine into the crucible and place it in a muffle furnace, heat it up to 500°C at a heating rate of 3°C / min, calcinate for 4 hours, and then grind the calcined product into powder and put it into an oxygen plasma cleaning machine. Lower treatment for 40min to obtain carbon nitride powder;

[0056] 3) Disperse 0.1 g of carbon nitride powder in 100 mL of deionized water, then ultrasonically peel for 16 h, and then centrifuge at 5000 rpm for 5 min to remove the lower layer precipitate to obtain a layered graphite ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com