Preparation method of N-acryloyl morpholine

A technology of acryloyl morpholine and morpholine, which is applied in the field of condensation preparation of N-acryloyl morpholine, can solve the problems of side reactions, poor stability of acryloyl chloride, long process route, etc., and achieves mild preparation conditions and easy availability of raw materials Strong, low overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

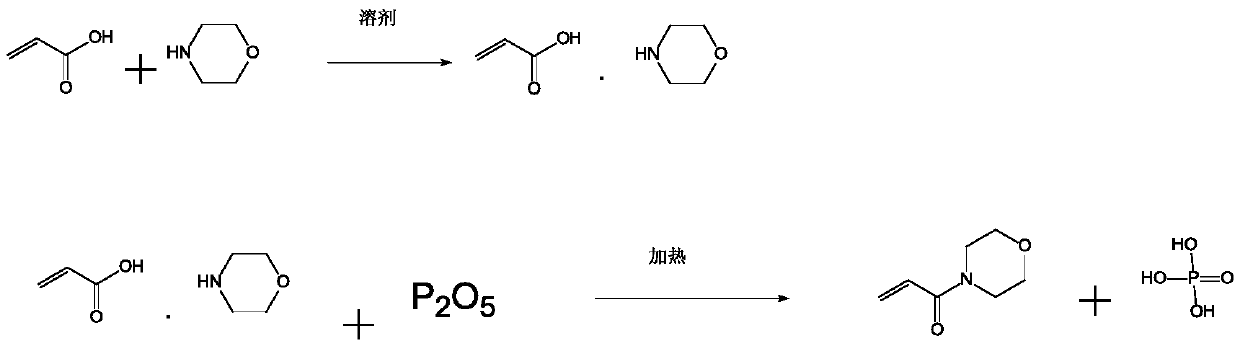

Method used

Image

Examples

Embodiment 1

[0033] Take 72.06g (1.0mol) of acrylic acid, 350mL of dichloroethane, 0.27g of p-hydroxyanisole, and 0.81g of cuprous chloride into a 1000mL four-necked flask and keep it at 25°C. Take morpholine 87.12g (1.0mol), control the temperature at 25±2℃, and add morpholine dropwise. After the reaction, it was filtered, and the filter cake was washed and dried in vacuo to obtain 155.2 g of yellow solid morpholine acrylate. It was added to 300 mL DMF, heated to 135°C, and 69.2 g of phosphorus pentoxide was added in three portions. After the reaction is over, the low boiling components are removed, and then 20% sodium hydroxide solution is added for neutralization. Add 1,2-dichloroethane for extraction, wash with saturated sodium chloride, add 0.23g of p-hydroxyanisole and 0.69g of cuprous chloride to the combined organic phase, distill 1,2-dichloroethane to reduce pressure, The N-acryloyl morpholine was further distilled at elevated temperature to obtain 109.52 g of N-acryloyl morpholi...

Embodiment 2

[0035] Take 72.06g (1.0mol) of acrylic acid, 350mL of ethanol, 0.27g of phenothiazine, and 0.51g of butylcatechol into a 1000mL four-neck flask and keep it at 10°C. Take morpholine 87.12g (1.0mol), control the temperature to 10±2℃, and add morpholine dropwise. After the reaction, it was filtered, and the filter cake was washed and dried in vacuum to obtain 151.5 g of yellow solid morpholine acrylate. Add it to 250mL dimethyl sulfoxide, heat to 135℃, add 69.2g of acetic anhydride in three portions, after the reaction is over, remove the low boiling components, then add 20% sodium carbonate solution to neutralize, add 1,2 -Dichloroethane extraction, saturated sodium chloride washing, adding 0.2g hydroquinone, 0.74g picric acid, and then distilling to recover 1,2-dichloroethane, reducing the pressure and increasing the temperature to further distill N-acryloyl To obtain 103.6 g of N-acryloylmorpholine, the yield was 73.4%, and the purity was 99.1%.

Embodiment 3

[0037] Take 72.06g (1.0mol) of acrylic acid, 350mL of dichloroethane, 0.27g of hydroquinone, and 0.81g of cuprous chloride into a 1000mL four-necked flask and keep it at 45°C. Take morpholine 87.12g (1.0mol), control the temperature at 45±2℃, and add morpholine dropwise. After the reaction, it was filtered, and the filter cake was washed and dried in vacuum to obtain 155.4 g of yellow solid morpholine acrylate. Add it to 350mL of dioxane, heat to 160°C, add 69.2g of phosphorus pentoxide in three times, after the reaction is over, remove the low boiling components, then add calcium hydroxide emulsion solution to neutralize, filter The filtrate is extracted with ethyl acetate, washed with saturated sodium chloride, 0.3g tert-butylphenol, 0.3g nitrobenzene, and then distilled to recover ethyl acetate, reduce the pressure, and raise the temperature to further distill N-acryloylmorpholine to obtain The yield of 107.6 g of N-acryloylmorpholine was 76.2%, and the purity was 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com