A cu@cumoo 4 /ti Fabrication of multi-element hierarchical nanorod electrodes

A nanorod and electrode technology, which is applied in the field of preparing Cu@CuMoO4/Ti nanorod electrodes, can solve the problems of short electrode service life, complicated preparation process, easy diffusion of oxygen atoms, etc., and achieve stable electrode performance and simple preparation process. , combined with a strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of multi-component hierarchical Cu@CuMoO4 / Ti nanorod electrode provided by the present invention comprises the following steps:

[0036] In the present invention, S1 is a pretreatment step for the porous titanium substrate: use sandpaper to polish the surface of the porous titanium substrate, put it in acetone and ultrasonically soak it to remove oil; then put it into 10% oxalic acid solution and heat it for 10 minutes to remove Oxide film on the surface; ultrasonic cleaning with ultrapure water and ethanol, drying, and standby; wherein, the porous titanium substrate has a pore diameter of 0.5-20 μm, which can be titanium plate, titanium mesh or titanium tube.

[0037] In the present invention, S2 is the preparation step of Cu@Cu(OH)F / Ti: that is, divalent copper salt, soluble fluoride, small molecule template agent, and hydrazine are mixed in a ratio of 1:2.0~3.5:4~8:5 Dissolve in water at a molar ratio of ~10, and stir evenly; transfer the mixed...

Embodiment 1

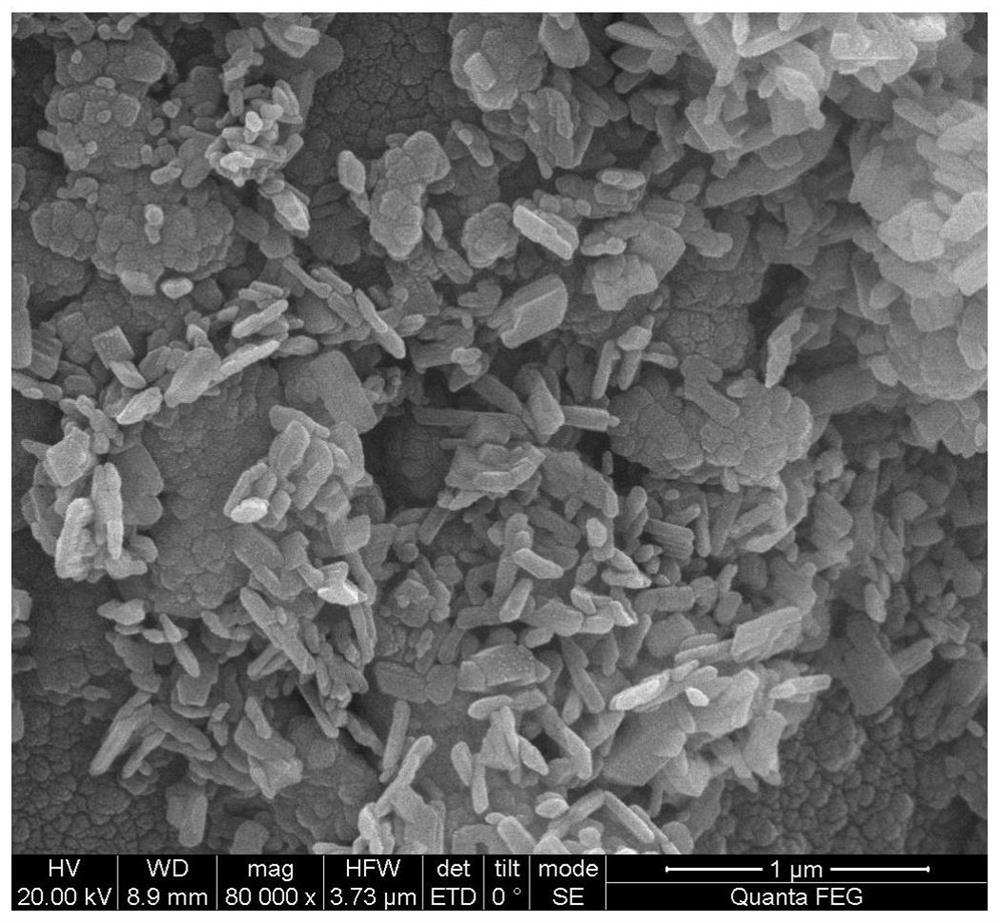

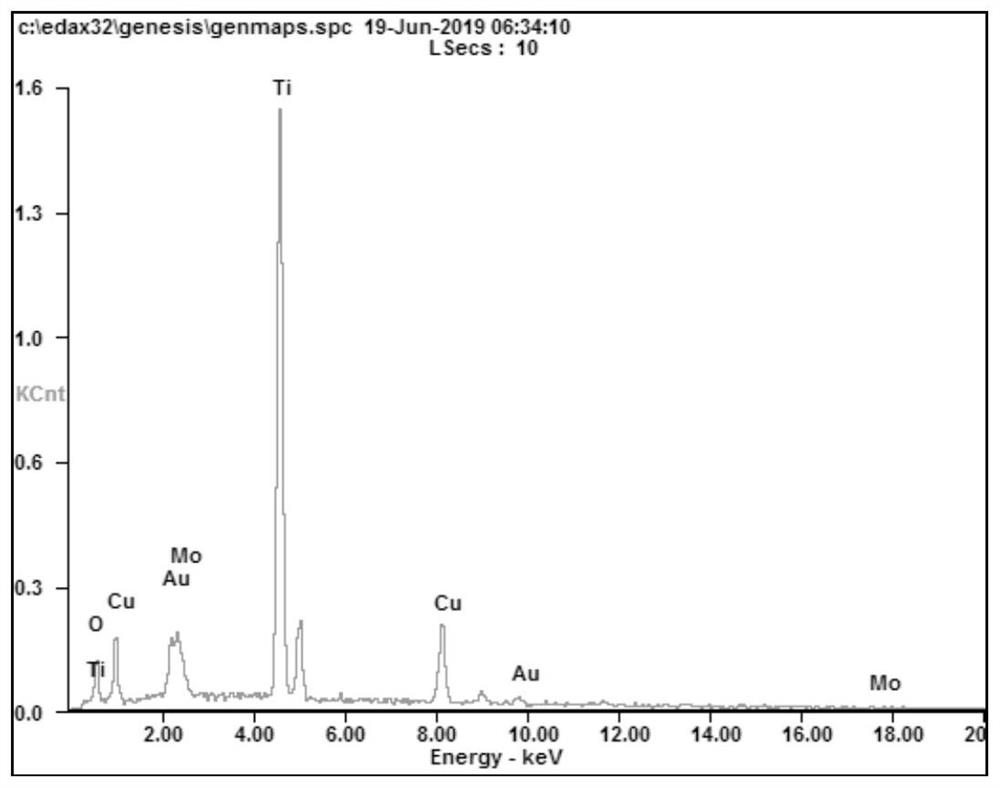

[0043] Example 1 Preparation of Cu@CuMoO by the method provided by the present invention 4 / Ti nanorod electrode

[0044] S1. Pretreatment of the porous titanium substrate: use sandpaper to polish the surface of the porous titanium substrate (5cm×5mm×1mm, with a pore size of 10 μm), put it into acetone and ultrasonically soak it to remove oil; then put it into 10% oxalic acid solution Heat and soak for 10 minutes to remove the oxide film on the surface; ultrasonically clean with ultrapure water and ethanol and dry for later use.

[0045] S2. Preparation of Cu@Cu(OH)F / Ti: Cu(NO 3 )2.6H 2 O, NH 4 F, glucose, hydrazine are dissolved in water with the molar ratio of 1: 2.5: 5: 5, stir evenly; The mixed solution is transferred in the reactor, and the porous titanium of S1 pretreatment is transferred to 170 after stirring with a magnetic stirrer for 20min. In an oven at ℃, react for 5 hours; after cooling, take out the titanium sheet, wash it with water, and dry it in vacuum for...

Embodiment 2

[0047] Embodiment 2: Cu@CuMoO provided by the present invention 4 / Ti nanorod electrode degrades printing and dyeing wastewater containing rhodamine B.

[0048] Cu@CuMoO prepared under the conditions of Example 1 of the present invention 4 / Ti nanorod electrode as cathode, Pt sheet as anode, add 0.1M Na 2 SO 4 As a supporting electrolyte, the constant current mode is used, and the current density is 10mA / cm 2 , the distance between the plates is 10mm, and the simulation of degrading rhodamine B containing 10mg / L can remove 98.7% of rhodamine B in 40min, and the effect is shown in Table 2.

[0049] time / min 0 10 20 40 Removal rate 0 56.3 82.5 98.7%

[0050] Compared with the prior art, the present invention has the following inventive effects:

[0051] 1. Compared with the traditional single metal oxide, the combination of Ti substrate and binary metal oxide greatly improves the conductivity and electrochemical activity. Cu@CuMoO loaded on the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com