Nano silver-chitosan-modified polybenzenesulfonamide antibacterial coating and preparation method thereof

A chitosan-modified, polybenzenesulfonamide technology, applied in coatings, polyester coatings, antifouling/underwater coatings, etc., can solve the problem of poor thermal and chemical stability of organic antibacterial agents, reduce It can improve the chemical stability and thermal stability, change the fluidity and permeability, and improve the antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

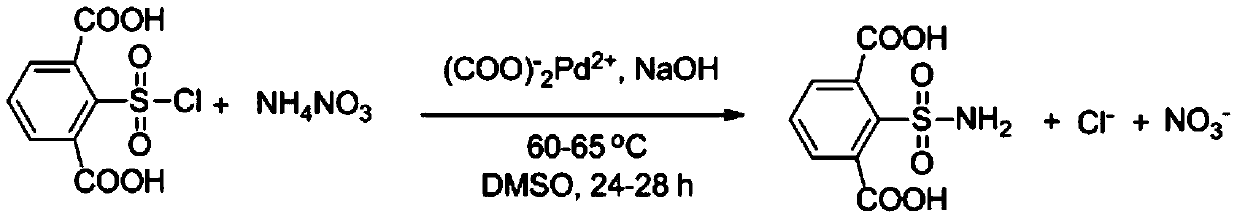

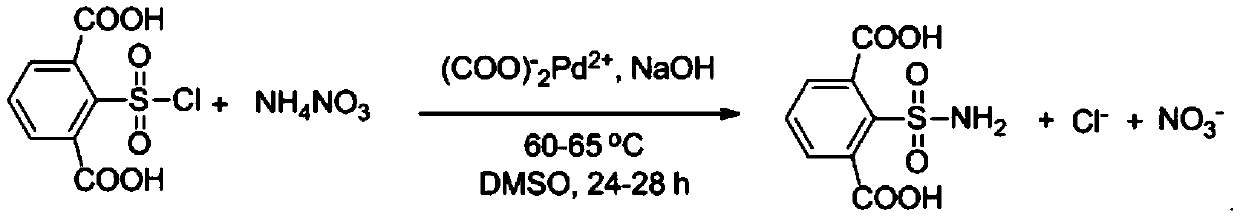

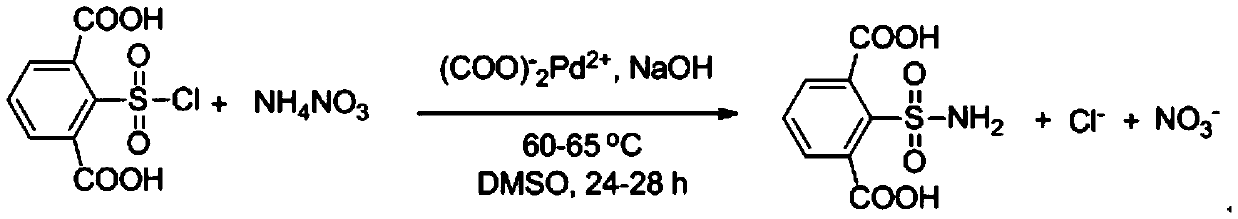

[0027] In order to achieve the above object, the present invention provides the following technical solutions: a nano-silver-chitosan modified polyphenylsulfonamide antibacterial coating and a preparation method thereof, comprising the following formula raw materials in parts by weight: 30-35 parts 2 , 6-di-carboxybenzenesulfonyl chloride, 32-38 parts of ammonium nitrate, 0.5-1.5 parts of catalyst, 3-6 parts of sodium hydroxide, 0.4-1 part of concentrated sulfuric acid, 0.1-0.5 parts of initiator, 10-30 parts of shell Polysaccharide, 3.5-6 parts of nano silver, 0.5-2 parts of dispersant. The preparation method includes the following experimental drugs: absolute anhydrous dimethyl sulfoxide, ethyl acetate, distilled water, ethylene glycol, dilute hydrochloric acid, and the structural formula of 2,6-di-carboxybenzenesulfonyl chloride is Its mass fraction is ≥96.5%, NH in ammonium nitrate 4 NO 3 The mass fraction is ≥94.2%, and the catalyst is palladium acetate (COO - ) 2 PD...

Embodiment 1

[0033] (1) Preparation of 2,6-bis-carboxybenzenesulfonamide: feed N into a dry 1000mL three-necked bottle 2 Remove the air, add 400mL of absolute anhydrous dimethyl sulfoxide, then weigh 30 parts of 2,6-di-carboxybenzenesulfonyl chloride and 32 parts of ammonium nitrate in sequence, stir well, then slowly add 3 parts of sodium hydroxide and 0.5 parts of catalyst, put the three-necked flask in a water bath and heat it to 60°C, and 2 The reaction was stirred at a constant speed in the atmosphere for 24 hours. The reaction was observed by TLC thin-layer chromatography. After the reaction was complete, the solution in the three-necked flask was transferred to a 2000mL separatory funnel, and 500mL distilled water and 800mL ethyl acetate were added for extraction. Ethyl ester organic layer, and then add 500mL distilled water to extract twice, will obtain the ethyl acetate organic layer and remove ethyl acetate by rotary evaporator reduced-pressure distillation, then carry out thin-l...

Embodiment 2

[0038] (1) Preparation of 2,6-bis-carboxybenzenesulfonamide: feed N into a dry 1000mL three-necked bottle 2 Remove the air, add 400mL of absolute anhydrous dimethyl sulfoxide, then weigh 31 parts of 2,6-di-carboxybenzenesulfonyl chloride and 33 parts of ammonium nitrate in sequence, stir well, then slowly add 4 parts of sodium hydroxide and 0.8 parts of catalyst, the three-necked flask was placed in a water bath and heated to 60°C, and 2 The reaction was stirred at a constant speed in the atmosphere for 24 hours. The reaction was observed by TLC thin-layer chromatography. After the reaction was complete, the solution in the three-necked flask was transferred to a 2000mL separatory funnel, and 500mL distilled water and 800mL ethyl acetate were added for extraction. Ethyl ester organic layer, and then add 500mL distilled water to extract twice, will obtain the ethyl acetate organic layer and remove ethyl acetate by rotary evaporator reduced-pressure distillation, then carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com