Copper-containing molecular sieve Cu-CHA, catalyst and use thereof

A molecular sieve and catalyst technology, which is applied in the application field of diesel vehicle exhaust gas treatment, can solve the problems of low temperature activity of catalyst and irreversible loss of catalytic activity, etc., and achieve the effects of increasing total acid content, excellent catalytic activity, and excellent NH3 storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

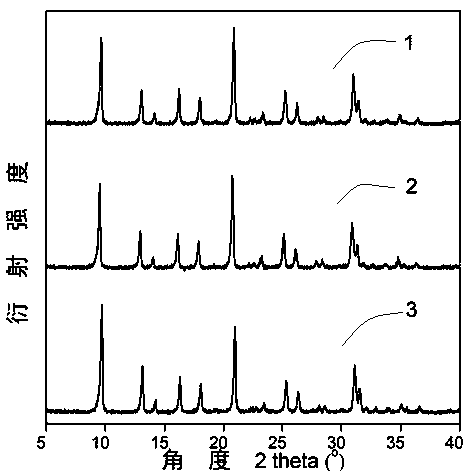

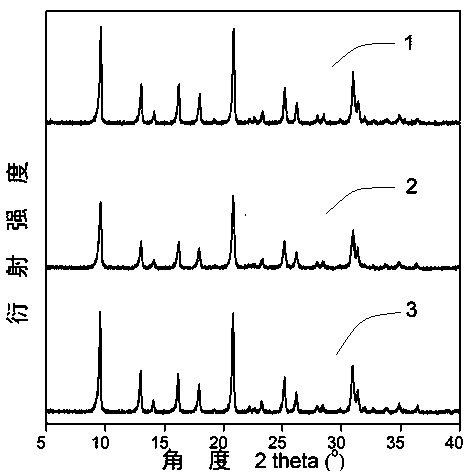

[0068] Example 1 Cu-SSZ-13 molecular sieve 1#

[0069] Add 220.0 grams of 25wt% N,N,N-trimethylamantadine hydroxide to 215.0 grams of deionized water, mix well, then add 5.6 grams of sodium hydroxide, stir until fully dissolved, and then add 12.4 grams of hydrogen Aluminum oxide, mixed well, then added 5.8 grams of boric acid, and finally added 100.0 grams of solid silica gel, and stirred thoroughly for 2 hours. The above mixture was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in an oven at 170°C for crystallization for 48 hours, taken out, quenched, and the crystallized product was subjected to solid-liquid separation, washed, dried and roasted to obtain Na-SSZ-13 molecular sieve 1#.

[0070] Then ammonium exchange is carried out to it, and the above-mentioned Na-SSZ-13 molecular sieve is exchanged at 90° C. for 2 hours with 1mol / L ammonium chloride solution at a ratio of solid-to-liquid ratio of 1:10, followed by solid-liquid ...

Embodiment 2

[0073] Example 2 Cu-SSZ-13 molecular sieve 2#

[0074] Add 161.0 grams of 25wt% N,N,N-trimethylamantadine hydroxide to 269.4 grams of deionized water, mix well, then add 3.6 grams of sodium hydroxide, stir until fully dissolved, and then add 25.0 grams of Sodium aluminate, mixed well, then added 2.4 grams of boric acid, and finally added 100.0 grams of solid silica gel, and stirred thoroughly for 2 hours. The above mixture was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a 160°C oven for crystallization for 60 hours, taken out, quenched, solid-liquid separation was carried out on the crystallized product, washed, dried and roasted to obtain Na-SSZ-13 molecular sieve 2#.

[0075] Then ammonium exchange is carried out to it, and the above-mentioned Na-SSZ-13 molecular sieve is exchanged at 90° C. for 2 hours with 1mol / L ammonium chloride solution at a ratio of solid-to-liquid ratio of 1:10, followed by solid-liquid separation, w...

Embodiment 3

[0078]Example 3 Cu-SSZ-13 molecular sieve 3#

[0079] Add 136.0 grams of 25wt% N,N,N-trimethylamantadine hydroxide solution into 20.0 grams of deionized water, mix well, then add 7.0 grams of sodium hydroxide, stir until fully dissolved, and then add 7.2 grams Pseudo-boehmite, fully mixed, then added 1.6 grams of boric acid, and finally added 320.0 grams of silica sol with a solid content of 30%, and stirred thoroughly for 2 hours. The above mixture was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in an oven at 170°C for crystallization for 60 hours, taken out, quenched, and the crystallized product was subjected to solid-liquid separation, washed, dried and roasted to obtain Na-SSZ-13 molecular sieve 3#.

[0080] Then carry out ammonium exchange on it, use 1mol / L ammonium chloride solution to exchange the above-mentioned Na-SSZ-13 molecular sieve 3# at 90°C for 2h at a solid-to-liquid ratio of 1:10, then carry out solid-liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com