Preparation of carbon nanotube/polyaniline/polysulfone conductive ultrafiltration membrane and membrane pollution online monitoring technology

A technology of carbon nanotubes and polyaniline, which is applied in the field of preparation of modified ultrafiltration membranes and membrane fouling monitoring, can solve problems such as pollution, permeability and service life reduction, limit membrane development and application, etc., and achieve sensitive and efficient methods. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

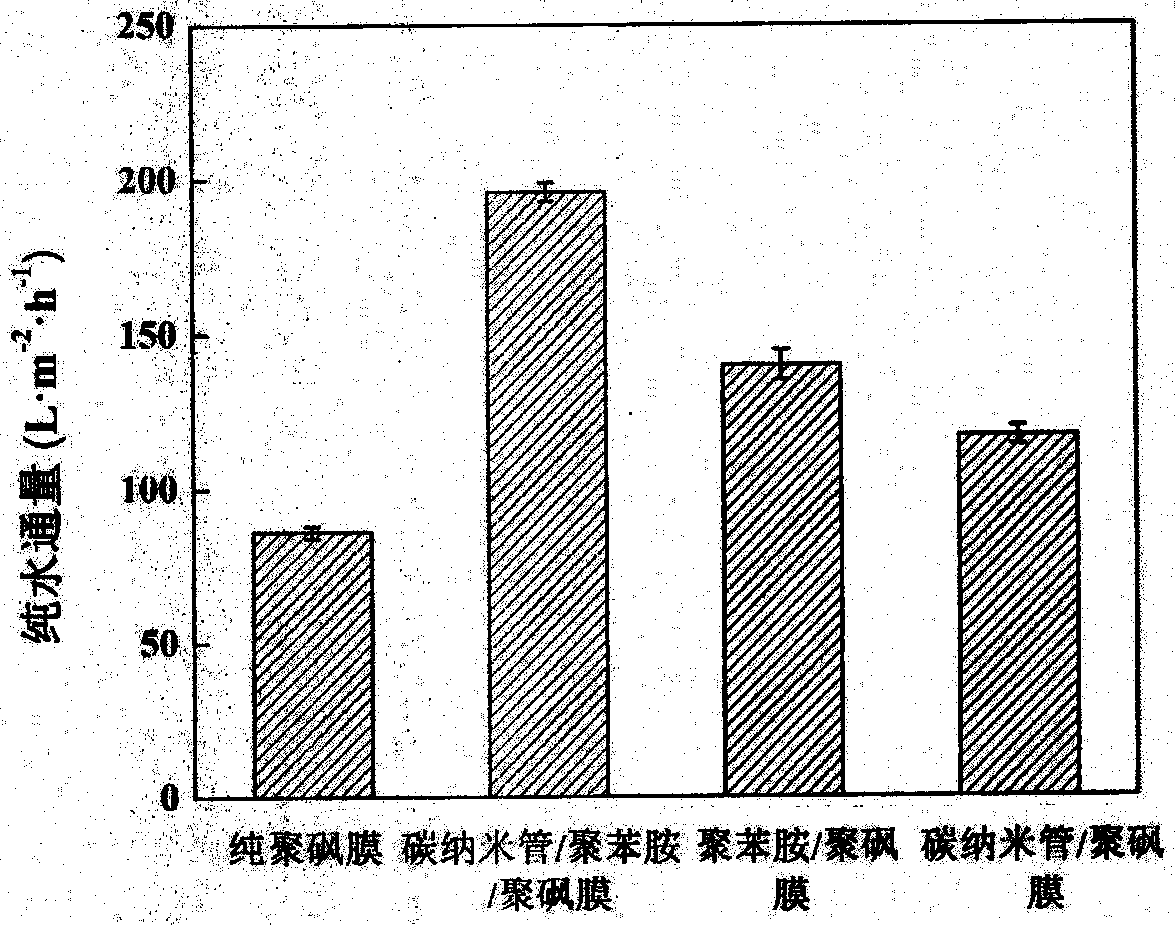

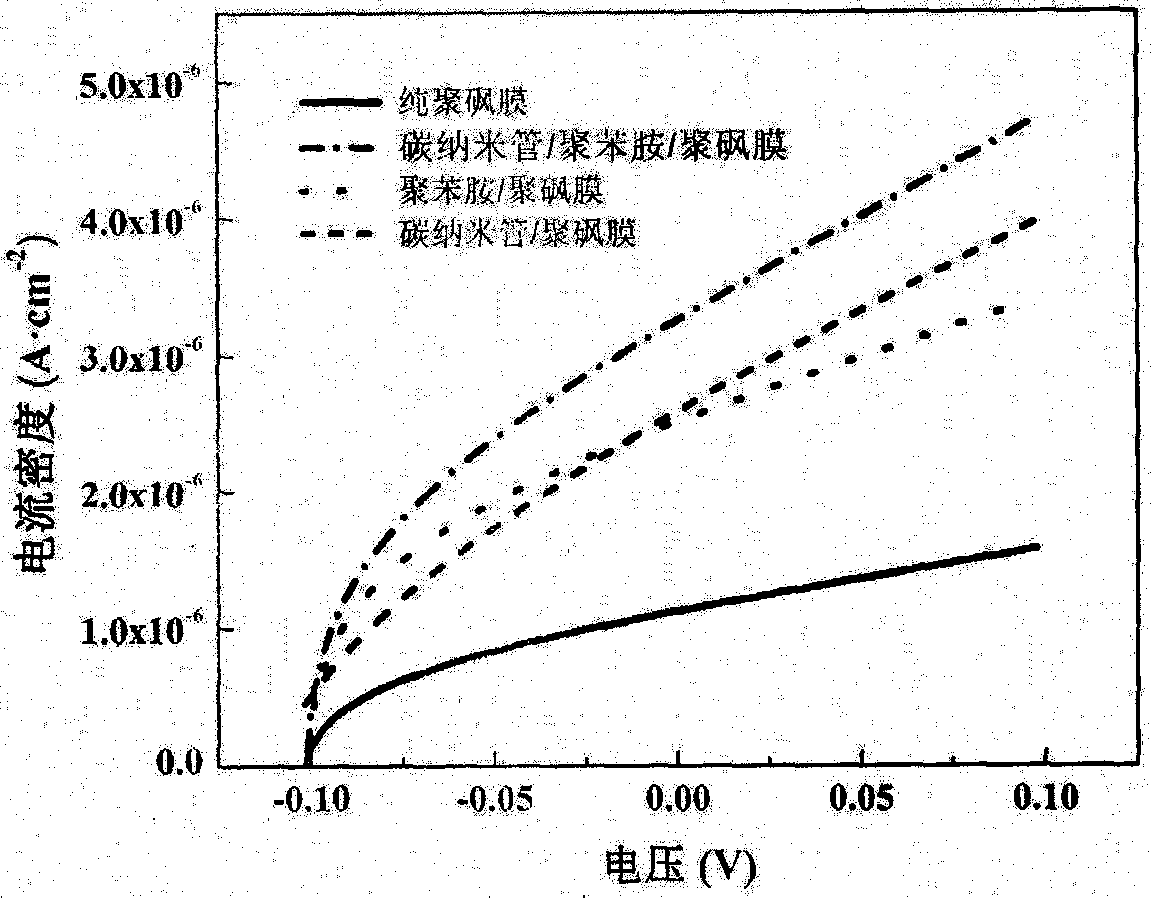

[0028] Example 1: A preparation method of pure polysulfone ultrafiltration membrane and online monitoring of membrane fouling, the specific steps are as follows:

[0029] (1) Preparation of a pure polysulfone ultrafiltration membrane. Weigh 6.8g of polysulfone and 0.4g of polyvinylpyrrolidone into 36.5ml of N,N-dimethylformamide, heat and stir at 60°C for 7h to prepare the casting solution, and place the casting solution in an ultrasonic and vacuum oven The defoaming treatment was carried out in the medium, and the membrane was scraped with a 200 μm thick film scraping rod and placed in a water coagulation bath for phase inversion to obtain a flat polysulfone ultrafiltration membrane.

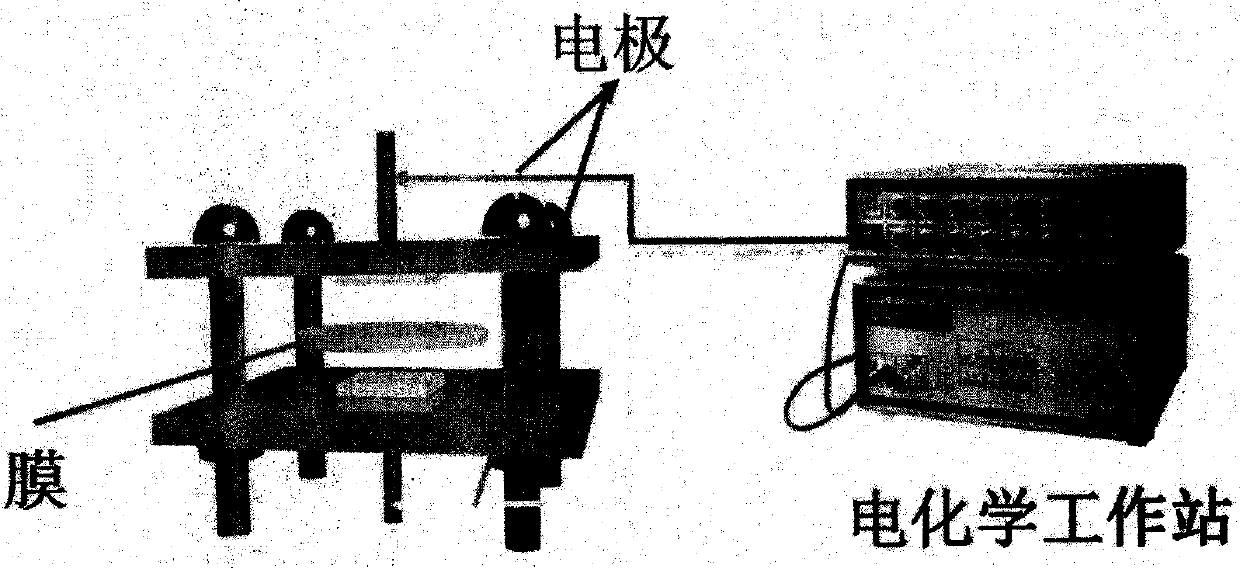

[0030] (2) Membrane fouling online monitoring technology. A prepared pure polysulfone ultrafiltration membrane was placed in a membrane cell with a titanium electrode and connected to an electrochemical workstation to filter a 1 g / L bovine serum albumin solution at 0.1 MPa. The change of memb...

example 2

[0031] Example 2: A preparation method of carbon nanotube / polyaniline / polysulfone conductive ultrafiltration membrane and online monitoring of membrane fouling, the specific steps are as follows:

[0032] (1) Polyaniline nanofibers were prepared by redox reaction by rapid mixing method. Weigh 3ml of aniline monomer and dissolve it in 100ml of 1mol / L HCl solution, which is called solution A; weigh 2g of ammonium persulfate and dissolve it in 100ml of 1mol / L HCl solution, and call it solution B. The two solutions A and B were quickly mixed, stirred vigorously for 2 minutes, and left to react for 6 hours. The polymerization solution was suction-filtered with a 0.22 μm microfiltration membrane, washed several times with methanol, acetone and deionized water, and dried in a vacuum oven at 60°C for later use.

[0033] (2) Preparation of a carbon nanotube / polyaniline / polysulfone ultrafiltration membrane. Weigh 0.085g of carbon nanotubes, 0.5g of polyaniline and 0.5g of polyvinylpyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com