Cesium lead halide inorganic perovskite quantum dot/transparent polymer composite thin membrane

A technology of composite films and quantum dots, which is applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of easily destroying the structure of quantum dots, and the luminescence performance of quantum dots is deteriorated, and achieves wide source of raw materials, good practical effects, and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

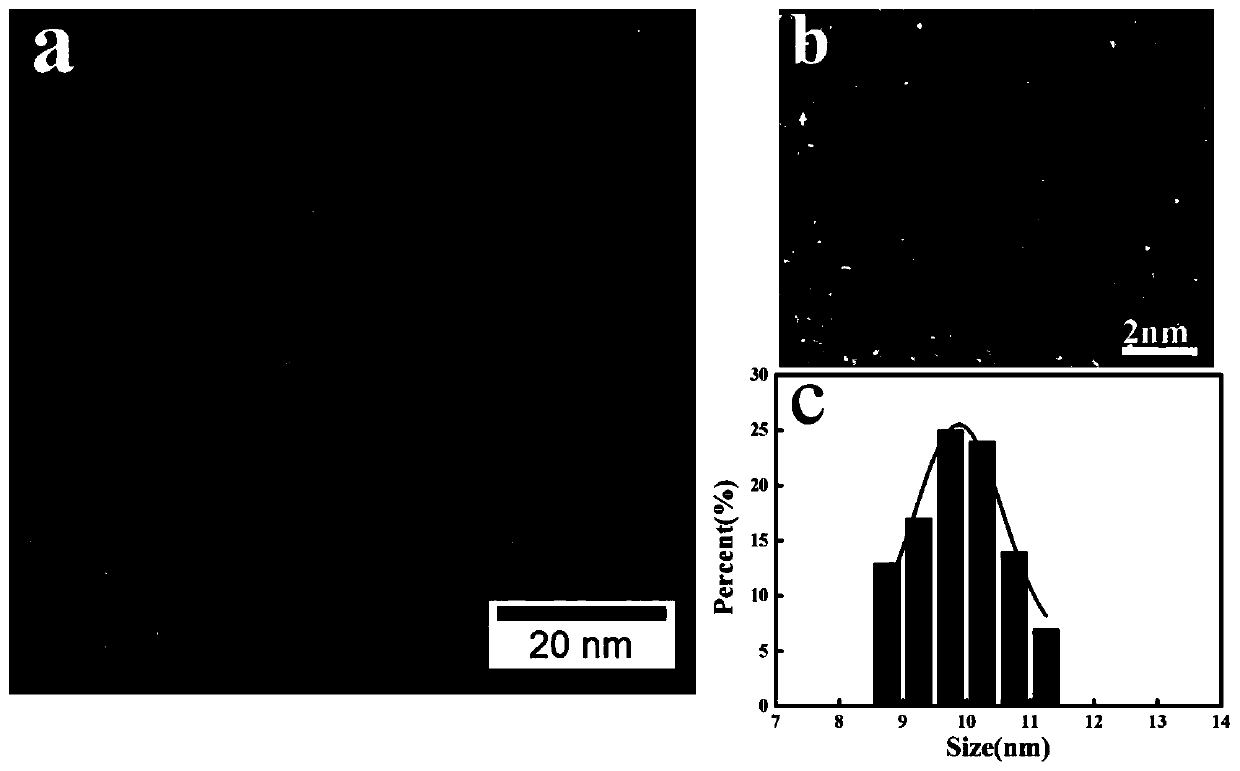

[0032] The cesium lead halide inorganic perovskite quantum dot / transparent polymer composite film of this embodiment is prepared by the following steps:

[0033] 1) Weigh 0.0734g PbBr 2 , 0.0425g CsBr powder, dissolved in 5mL N,N-dimethylformamide (DMF), stirred for 30min (stirring speed is 200rpm) to fully dissolve; then dropwise added surface ligand oleic acid 0.5mL (OA ) and oleylamine 0.25mL (OAm), stirred for 5min (stirring speed is 200rpm), after being completely dissolved, the precursor solution was obtained;

[0034] 2) Put ethylene-vinyl acetate copolymer (EVA) resin particles and polytetrafluoroethylene circular mold into absolute ethanol for 30 minutes (ultrasonic power 400W), dry and set aside, the diameter of the mold is 1.5mm, and the groove depth is 0.5mm Weigh 1g of EVA resin particles into 10mL of toluene, stir at 70°C for 30min (stirring speed is 200rpm) to fully dissolve to obtain EVA solution.

[0035] 3) Use a dropper to absorb 0.2mL precursor solution, ...

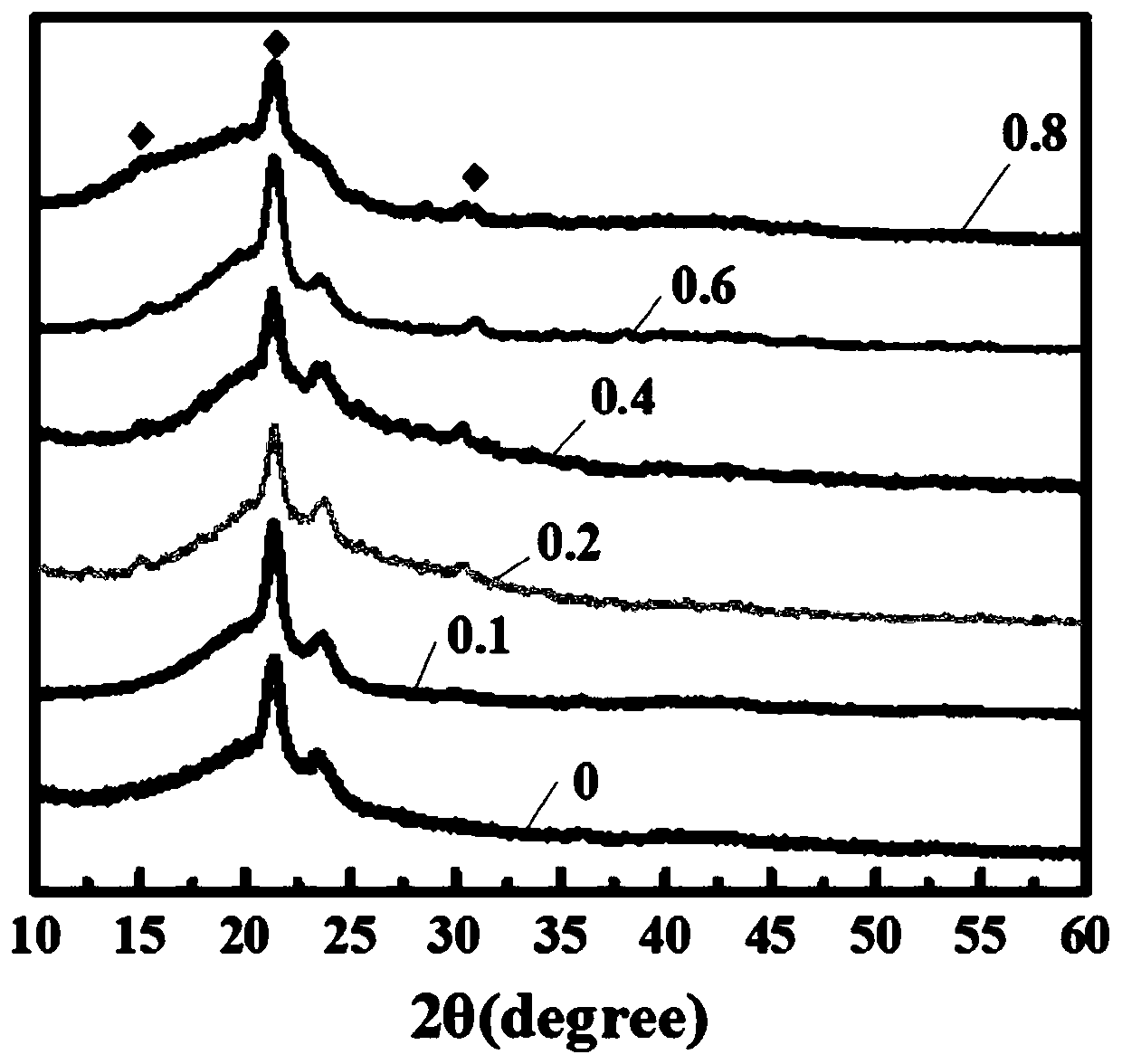

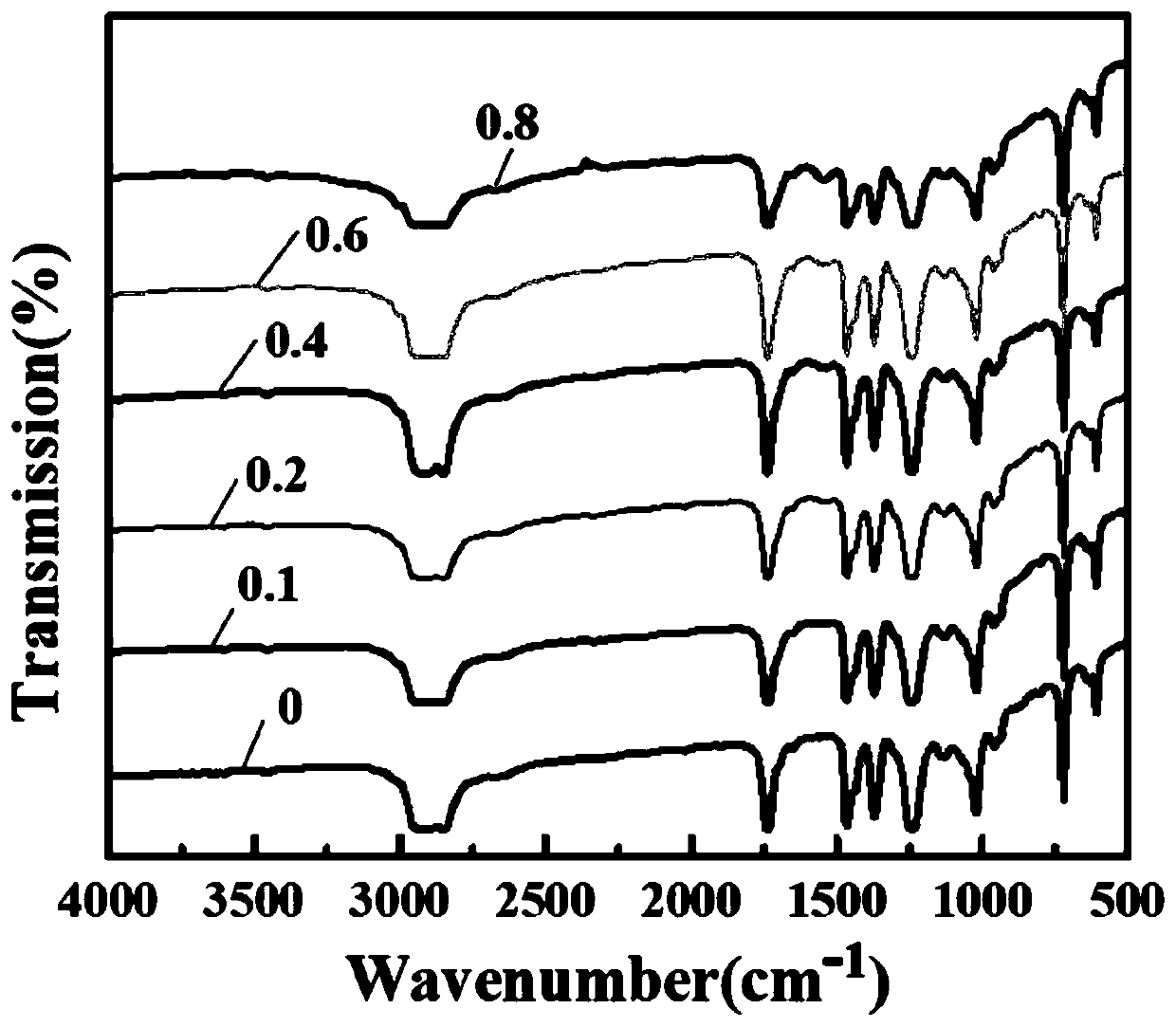

Embodiment 2-5

[0038] The difference between the cesium lead halide inorganic perovskite quantum dot / transparent polymer composite film of this example and the preparation method of Example 1 is that in step 3), the dropping amount of the precursor solution is 0.1mL, 0.4mL , 0.6mL, 0.8mL.

Embodiment 6

[0040] The difference between the cesium lead halide inorganic perovskite quantum dot / transparent polymer composite film of the present embodiment and the preparation method of embodiment 1 is that in step 3), the stirring speed is 300rpm; the temperature of the polymer solution is 80 ℃.

[0041] 2. Comparison ratio

[0042] The difference between the preparation method of the film of the comparative example and that of Example 1 is that in step 3), the amount of the pre-extraction solution added is 0 mL.

[0043] 3. Experimental example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com