Composite electric-conduction hydrogel preparation method

A composite conductive and hydrogel technology, applied in the preparation/purification of carbon, etc., can solve the problems of separation of conductive fillers, poor biocompatibility of hydrogels, unstable structure of conductive hydrogels, etc., and achieve good conductivity. , the effect of increasing the thickness of the interface layer and increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

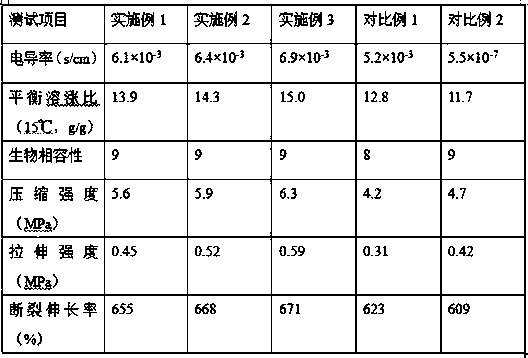

Examples

Embodiment 1

[0029] Preparation of the mixture:

[0030] Soak the flax fibers in the biogas solution for 1 hour, take them out, put them in a mold room with a temperature of 40°C and a relative air humidity of 70%, let them stand for 1 week to mold, then move the moldy flax fibers into a fermenter and feed them to the fermentation tank. Add quality water such as moldy flax fiber into the tank, stir evenly, seal the tank mouth, and let it stand for fermentation at 35°C for 3 days; Carbonize at 200°C for 1 hour to obtain a self-made porous carbon material. Mix the self-made porous carbon material and a nickel nitrate solution with a mass fraction of 30% at a mass ratio of 1:5 to obtain a mixed solution.

[0031] Preparation of homemade conductive filler:

[0032] Move the above mixed solution into an ultrasonic oscillator, immerse and mix with ultrasonic oscillation at a frequency of 40 kHz for 1 hour, filter after the ultrasonic oscillation and impregnation, separate the impregnated filter...

Embodiment 2

[0040] Preparation of the mixture:

[0041] Soak the flax fibers in the biogas solution for 1 hour, take them out, put them in a mold room with a temperature of 45°C and a relative air humidity of 75%, let them stand for 1 week to mold, then move the moldy flax fibers into a fermenter and feed them to the fermentation tank. Add quality water such as moldy flax fiber into the tank, stir evenly, seal the tank mouth, and let it stand for fermentation at 40°C for 4 days; Carbonize at 250°C for 1 hour to obtain a self-made porous carbon material. Mix the self-made porous carbon material and a nickel nitrate solution with a mass fraction of 30% at a mass ratio of 1:5 to obtain a mixed solution.

[0042] Preparation of homemade conductive filler:

[0043] Move the above mixed solution into an ultrasonic oscillator, immerse and mix with ultrasonic oscillation at a frequency of 45 kHz for 1 hour, filter after the ultrasonic oscillation and impregnation, separate the impregnated filter...

Embodiment 3

[0051] Preparation of the mixture:

[0052] Soak the flax fibers in the biogas solution for 2 hours, take them out, put them in a mold room with a temperature of 50°C and a relative air humidity of 80%, and let them stand for 2 weeks to mold. Add quality water such as moldy flax fiber into the tank, stir evenly, seal the tank mouth, and let it stand for fermentation at 45°C for 5 days; Carbonize at 300°C for 2 hours to obtain a self-made porous carbon material. Mix the self-made porous carbon material and a nickel nitrate solution with a mass fraction of 30% at a mass ratio of 1:5 to obtain a mixed solution.

[0053] Preparation of homemade conductive filler:

[0054] Move the above mixed solution into an ultrasonic oscillator, immerse and mix with ultrasonic oscillation at a frequency of 50 kHz for 2 hours, filter after the ultrasonic oscillation and impregnation, separate the impregnated filter residue, put the impregnated filter residue into the sintering furnace, and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com