Graphite phase carbon nitride/polymer composite material and preparation method, energy storage material

A technology of graphite phase carbon nitride and composite materials, applied in the field of composite materials, can solve problems such as the drop of breakdown field strength, and achieve the effects of improving dielectric constant, large output and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

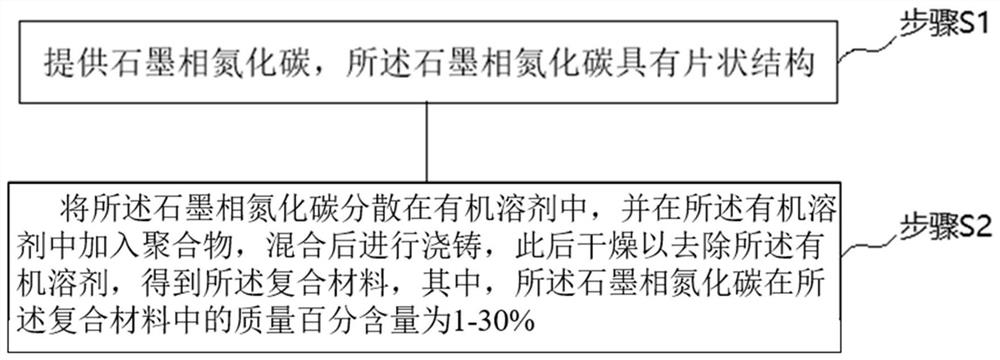

[0039] like figure 1 As shown, the preparation method of the graphite phase carbon nitride / polymer composite material according to the embodiment of the present invention comprises the following steps:

[0040] Step S1, providing graphitic carbon nitride, the graphitic carbon nitride has a flake structure.

[0041] Wherein, the planar size of the graphitic carbon nitride having a flake structure may be 50-1500 nm, and the thickness may be 5-50 nm. When the graphite phase carbon nitride is in the shape of a disc, the average diameter of the plane is 80-400nm, and the thickness is about 20-30nm, the composite material has more excellent comprehensive properties.

[0042] The graphite phase carbon nitride can use commercially available graphite phase carbon nitride of flake structure, preferably, prepare by the following method:

[0043] Using at least one of urea, melamine, dicyandiamide, and thiourea as raw materials, after calcination, the resulting product is ultrasonically...

Embodiment 1

[0054] 1) Preparation of graphite phase carbon nitride

[0055] Take 10g of urea and place it in a ceramic crucible with a cover, heat it up to 550°C in a muffle furnace, keep it warm for 4 hours, then cool it down naturally, wash it with a small amount of water and ethanol three times, and vacuum filter the filter cake at 80°C Dry for 8 hours at lower temperature to obtain dry graphitic carbon nitride (g-C 3 N 4 ).

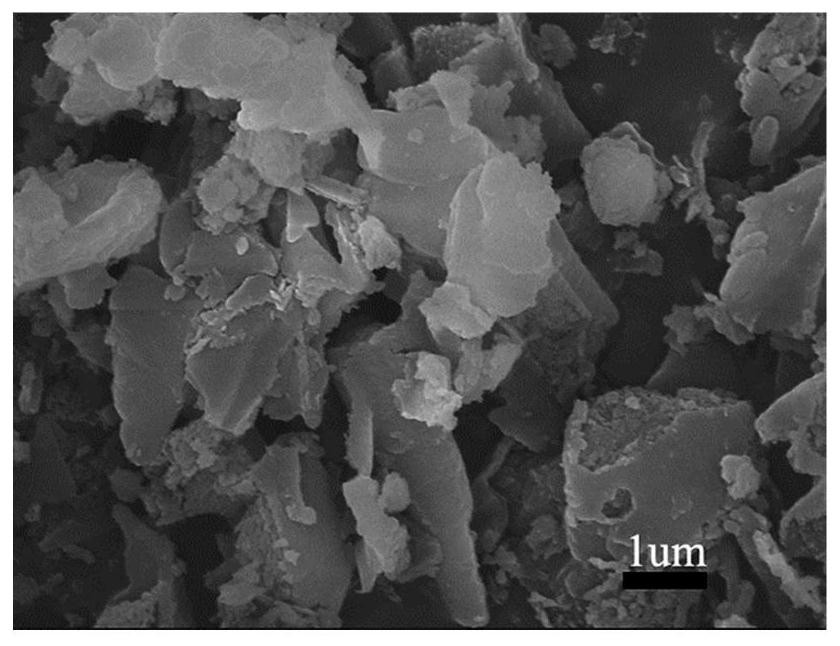

[0056] figure 2 Its SEM photograph is shown. Depend on figure 2 It can be seen that the prepared graphitic carbon nitride has a flake structure. Measure at least 100 g-C on SEM 3 N 4 According to the size of the particles, the average size of the plane is about 1000-1500nm in length, 500-900nm in width, and the thickness of the particles is about 50nm.

[0057] 2) Preparation of composite materials

[0058] Take 0.02g of graphite phase carbon nitride prepared in step 1) and add it to 30mL of N,N-dimethylformamide, then continue to add 1.98g of polyviny...

Embodiment 2

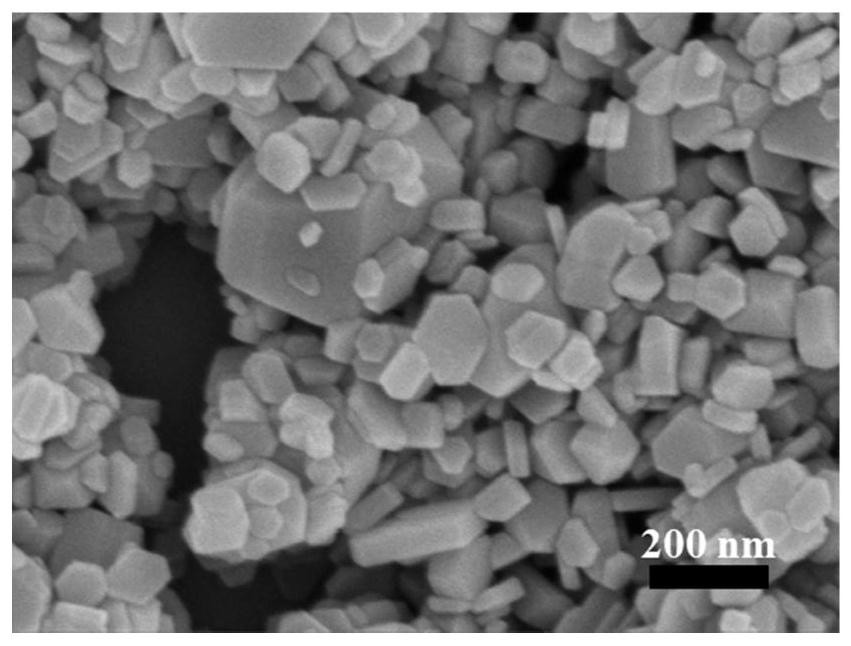

[0064] Except that the product after natural cooling in the preparation of 1) graphite phase carbon nitride in the above-mentioned embodiment 1 was subjected to ultrasonic treatment in a mixed solution of ethanol and water for 10 hours and then centrifugally filtered and dried, the same as in Example 1 method to prepare graphitic carbon nitride and measure its particle size. SEM photo shows the obtained graphitic carbon nitride g-C 3 N 4 It is a disc-like structure. The plane average size diameter of the particles is about 290-340nm, and the thickness is about 30nm.

[0065] According to the same method as in Example 1 above, a composite material was prepared using the graphite phase carbon nitride obtained above, and the properties of the composite material were tested. Wherein, the sample number of the obtained composite material is marked as 2#, and its dielectric constant and breakdown field strength are tested according to the same method as in Example 1, and its energ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com