Resin, preparation method thereof, and process for preparing ultra-high purity rare earth oxide by using resin

A technology of rare earth oxides and resins, which is applied in the field of preparation of ultra-high-purity rare earth oxides, can solve the problems of low separation coefficient and crossover of impurity removal rates, and achieve the effect of solving separation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of above-mentioned resin is:

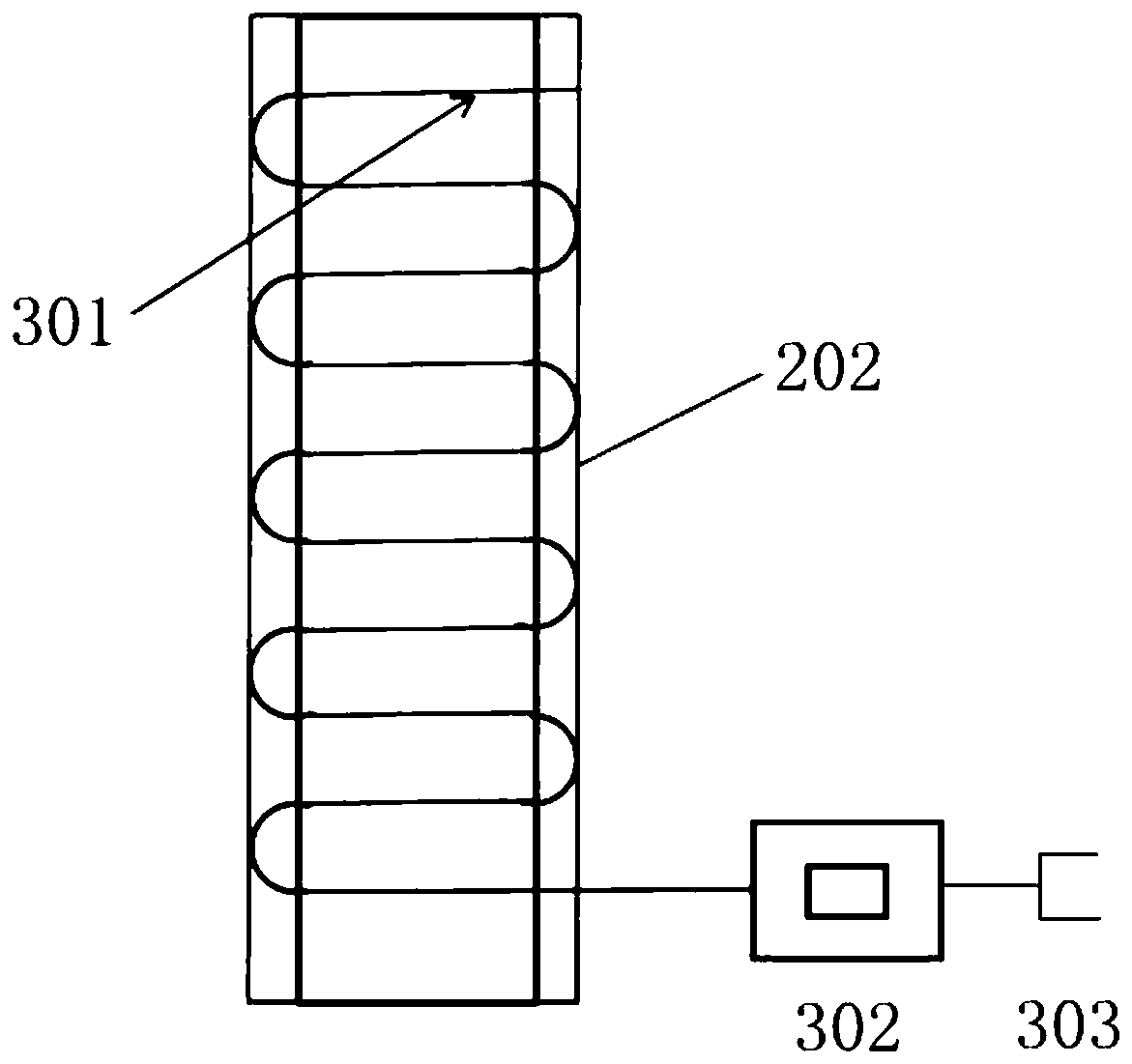

[0052] Take a certain amount of XAD-4 macroporous adsorption resin in a beaker, add enough absolute ethanol to completely submerge XAD-4 macroporous adsorption resin, soak for 12 hours, wait for the resin to fully swell, take out the resin with ultra-pure Rinse with water several times until the eluent is clear and free of floating impurities. Then soak in 4%-5% HCl aqueous solution for 4 hours, then wash with ultra-pure water until neutral, then soak with 4%-5% NaOH solution for 4 hours, wash with ultra-pure water until neutral, and remove the water on the surface of the resin as much as possible Then put it into a freeze-drying box to dry for later use. Take a certain amount of D2EHDGAA and dissolve it in 0.45-0.55mol / L kerosene, and then add a certain amount of pretreated XAD-4 resin into it. The volume ratio of resin to kerosene liquid is 1:1.7-1:2.0. Shake in a constant temperature shaker for 24 hours, and the...

Embodiment 1

[0060] A kind of resin, comprises each component of following weight part: extraction agent D 2 EHDGAA 50 parts, load resin XAD-4 100 parts.

[0061] The preparation method of above-mentioned resin is:

[0062] Take 1L XAD-4 macroporous adsorption resin in a beaker, add enough absolute ethanol to completely immerse XAD-4 macroporous adsorption resin, soak for 12 hours, wait for the resin to fully swell, take out the resin and rinse it with ultrapure water Several times until the eluent is clear and free of floating impurities. Then soak with 5wt% HCl aqueous solution for 4 hours, then wash with ultrapure water until neutral, then soak with 5wt% NaOH solution for 4 hours, then wash with ultrapure water until neutral, remove the water on the surface of the resin as much as possible and put it into a freeze-drying box Dry inside and set aside. Take 334g D2EHDGAA and dissolve it in 1.8L kerosene, then add 1LXAD-4 resin which has been pretreated in advance, shake it in a constan...

Embodiment 2

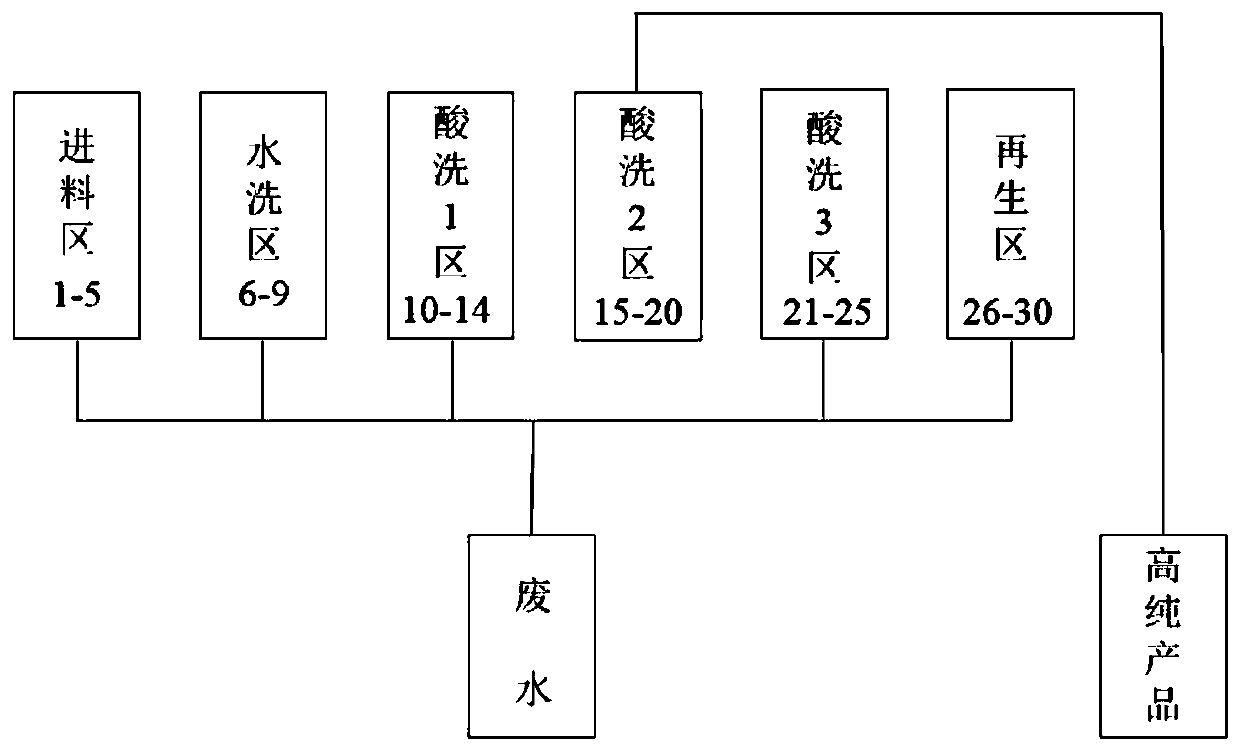

[0065] Preparation of ultra-high-purity ytterbium oxide: add ytterbium oxide with a relative purity of 99.9% and dilute hydrochloric acid to dissolve, and make 50g / L (REO) YbCl 3 Solution, adjust the pH to 2-3, add it to the material tank of the feeding area, adjust the flow rate to 75mL / h, add ultrapure water to the material tank in the washing area, adjust the flow rate to 300mL / h, add 1.5mol / h to the material tank of the pickling area 1 L of HCl solution, adjust the flow rate to 95mL / h, add 2.0mol / L HCl solution to the pickling zone 2 material tank, adjust the flow rate to 80mL / h, add 2.6mol / L HCl solution to the pickling zone 3 material tank, adjust The flow rate is 45mL / h, pure water is added to the material tank in the regeneration zone, and the flow rate is adjusted to 0.5L / h. The liquid in the high-purity product tank was collected, and the rare earth content was detected by titration method to be 31.2g / L, and the yield was 62.4%. The liquid is precipitated with oxali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com