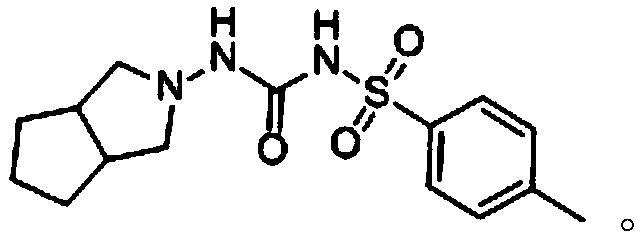

Gliclazide tablets (II) and preparation method thereof

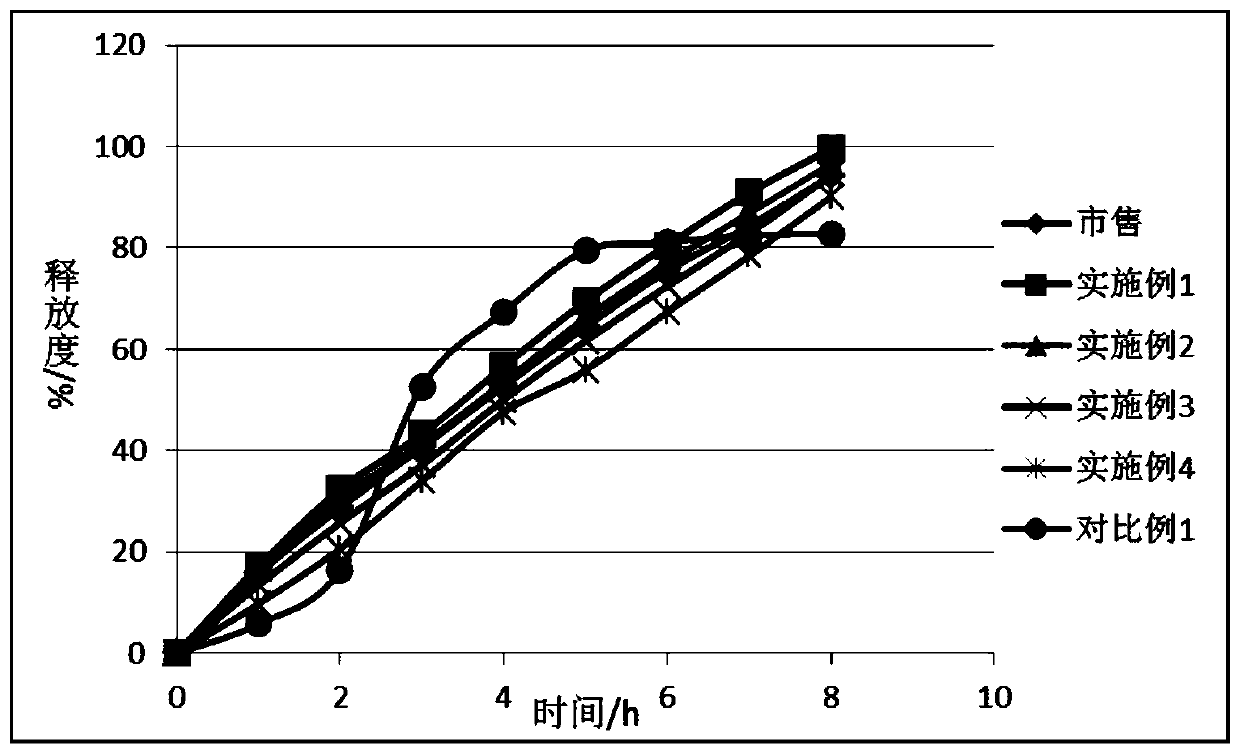

A technology for gliclazide tablets and tablet compression, which is applied in the field of gliclazide tablets and its preparation, can solve the problems of high risk factor, unfavorable explosion protection, etc., and achieve the effect of ensuring safety and avoiding sudden release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides the preparation method of the gliclazide tablet (II) described in the above technical scheme, comprising the following steps:

[0032] In a fluidized bed, gliclazide, diluent and binder are mixed to obtain a mixture;

[0033] After heating glyceryl behenate at 65-80°C to melt, fluidized spray granulation is carried out with the mixture to obtain granules;

[0034] The granules are mixed with a lubricant and then tableted to obtain the gliclazide tablet (II).

[0035] In the present invention, the gliclazide, the diluent and the binder are mixed in a fluidized bed to obtain a mixture. In the present invention, when the gliclazide, the diluent and the binder are mixed, the parameters of the fluidized bed are preferably: air inlet temperature 60°C, wind speed 20m 3 / h, atomization pressure 1.8kg / cm 2 , the liquid feeding speed is 0.5g~1.0g / min, after the liquid feeding is finished, reduce the wind speed to 18m 3 / h, then dry. In the...

Embodiment 1

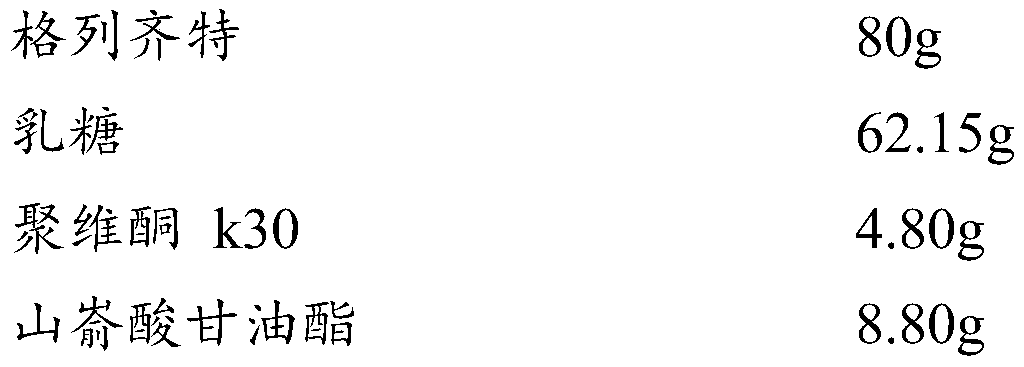

[0040] prescription:

[0041]

[0042] Additional materials

[0043] Micronized silica gel 1.50g

[0044] Magnesium stearate 0.75g

[0045] Total weight 160g

[0046] Preparation Process:

[0047] ① Pass the lactose through an 80-mesh sieve for later use.

[0048] ②Take glyceryl behenate, heat it at 65°C until it melts, and keep it warm until it is fluidized and sprayed for granulation.

[0049] ③ Weigh gliclazide, lactose and povidone k30, place them in a multifunctional fluidized bed, set the inlet air temperature at 60°C, and wind speed at 20m 3 / h, atomization pressure 1.8kg / cm 2 , The feeding speed is controlled at 0.5g / min. After the liquid intake is over, reduce the wind speed to 18m 3 / h, continue to dry, and measure the moisture of the granules with a halogen moisture analyzer until the moisture content of the granules does not exceed 3.0%. 1.5mm sieve whole grain.

[0050] ④Add prescription amount of micropowder silica gel and magnesium stearate and mix ...

Embodiment 2

[0052] prescription:

[0053]

[0054] Additional materials

[0055] Micronized silica gel 1.50g

[0056] Magnesium stearate 0.75g

[0057] Total weight 160g

[0058] Preparation Process:

[0059] ① Pass the lactose through an 80-mesh sieve for later use.

[0060] ②Take glyceryl behenate, heat it at 65°C until it melts, and keep it warm until it is fluidized and sprayed for granulation.

[0061] ③ Weigh gliclazide, lactose and povidone k30, place them in a multifunctional fluidized bed, set the inlet air temperature at 60°C, and wind speed at 20m 3 / h, atomization pressure 1.8kg / cm 2 , The feeding speed is controlled at 0.5g / min. After the liquid intake is over, reduce the wind speed to 18m 3 / h, continue to dry, and measure the moisture of the granules with a halogen moisture analyzer until the moisture content of the granules does not exceed 3.0%. 1.5mm sieve whole grain.

[0062] ④Add prescription amount of micropowder silica gel and magnesium stearate and mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com