Absorbable magnesium alloy stent with polymer and TiO2 nanotube coating and preparation method thereof

A magnesium alloy stent, nanotube technology, applied in coating, medical science, surgery, etc., can solve the problem of multiple coating on stent surface, improve biocompatibility, improve corrosion resistance, and solve the problem of excessive corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

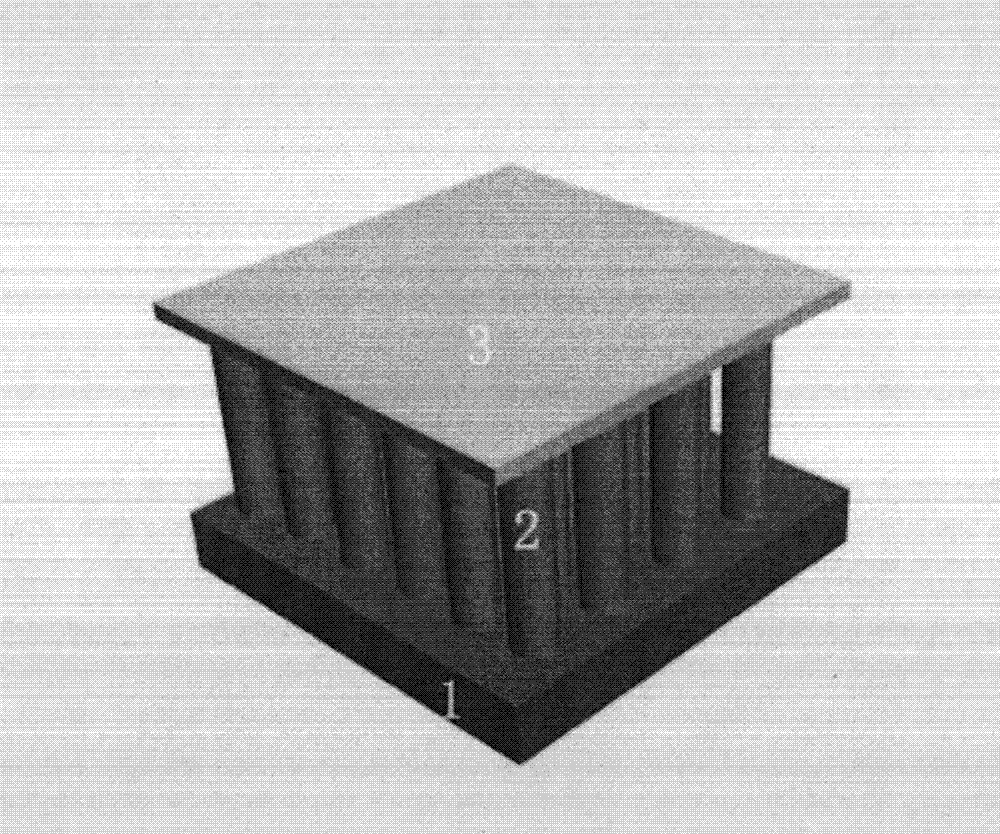

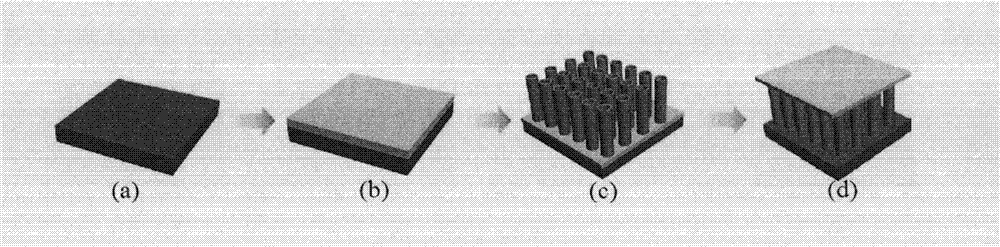

[0032]Magnesium alloy AZ81 (mass fraction is Al (8-8.5%), Zn (0.5-1%), Taiyuan University of Technology) is laser engraved into a vascular stent, and then it is ultrasonically cleaned in a hydrochloric acid solution with a mass concentration of 5%. After 1 hour, it was placed in a cell shaker with a power of 300W, ultrasonically cleaned for 20 minutes, and then vacuum-dried. The Ti-4Zr alloy coating was prepared on the dry surface of the magnesium alloy stent by plasma surface sputtering method, the used targets were titanium target and copper target, the atmosphere was argon, and the sputtering time was 30 minutes.

[0033] Then, TiO was prepared on the surface of magnesium alloy Ti-4Zr coating by anodic oxidation method. 2 Nanotubes, the electrolyte composition is glycerol-water (1:2vol.%) / 0.1M NH 4 F, the oxidation time is 0.5-6h, and the oxidation voltage is 5V. Then hang the bracket after cleaning and immerse it in an acetone solution with a mass concentration of paclit...

Embodiment 2

[0037] Experimental conditions and operation steps of embodiment 2 are exactly the same as embodiment 1, just prepare TiO in anodic oxidation 2 In the process of nanotube coating, change the anodizing voltage to 10V, 15V, 20V, 25V, 30V, 35V, 40V, 45V, 50V.

[0038] Cytotoxicity tests showed that the prepared polymer TiO 2 Nanotube-coated absorbable magnesium alloy stents have good biocompatibility. Soak the prepared stent in Hank's dynamic simulated body fluid for different time and test the corrosion rate of drug and magnesium alloy. The drug release results show that the drug release rate is 40%-50% in 90 days, and the drug release is slow. The magnesium alloy corrosion test results show that Metal stents were basically degraded in 400-500 days.

Embodiment 3

[0040] Experimental conditions and operation steps of embodiment 3 are exactly the same as embodiment 1, just prepare TiO in anodic oxidation 2 In the process of nanotube coating, the composition of the anodic oxidation electrolyte was changed to glycerol-water (1: 2vol.%) / 0.2M NH 4 F and glycerol-water (1:2vol.%) / 0.3M NH 4 F.

[0041] Cytotoxicity tests showed that the prepared polymer TiO 2 Nanotube-coated absorbable magnesium alloy stents have good biocompatibility. Soak the prepared stent in Hank's dynamic simulated body fluid for different time and test the corrosion rate of drug and magnesium alloy. The drug release results show that the drug release rate is 35% in 90 days, and the drug release is slow. The magnesium alloy corrosion test results show that the metal stent is in After 340 days, the degradation is basically completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com