High-strength sealing plugging agent

A sealing and high-strength technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems affecting the consolidation strength of the plugging agent and the large resistance to diffusion, etc., and achieve improved thermal stability and resistance to heat and humidity properties, acceleration of curing, and effects of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of modified calcium-based degassing agent is as follows:

[0025] (1) Dissolve 0.2mol magnesium nitrate, 0.1mol aluminum nitrate, 0.1mol iron nitrate, 0.2mol calcium acetate in 1500ml deionized water to obtain a transparent solution; (2) add 150ml polyethylene glycol to the transparent solution as a dispersant , put the reaction solution in a constant temperature water bath at 80°C, under the condition of mechanical stirring, slowly add a mixture of sodium carbonate and sodium hydroxide with a molar ratio of 1:2 to adjust the pH=12, the solution is in the state of white sol, and continue to stir for 30 minutes (3) After the reaction is completed, let it stand and age for 12 hours, then heat and evaporate to dryness until it becomes a paste, then wash it with alcohol in a centrifuge, dry it in an oven at 120°C, and grind it to a particle size of 120-160 mesh; (4) Grind the The powder is calcined at 800°C for 30 minutes to obtain a modified calcium-...

Embodiment 2

[0028] Fluorenyl epoxy resin (9,9-bis[(2,3-epoxypropoxy)phenyl]fluorene), epoxy resin E-51, basic phenolic resin F-51, solvent iso Propanol, coupling agent octadecyltrimethoxysilane, filler, modified calcium-based degassing agent, and curing agent are mixed according to the mass ratio of 15:10:10:30:5:20:5:5 to prepare a High-strength sealing and plugging agent. Wherein, the filler is a compound of superfine cement powder and PVA fiber in a mass ratio of 4:1. The curing agent is a mass ratio compound of benzophenone imine and 9,9 bis(4-aminophenyl)fluorene. The modified calcium-based degasser uses the degasser prepared in Example 1. The application temperature of the high-strength sealing and plugging agent is 100°C.

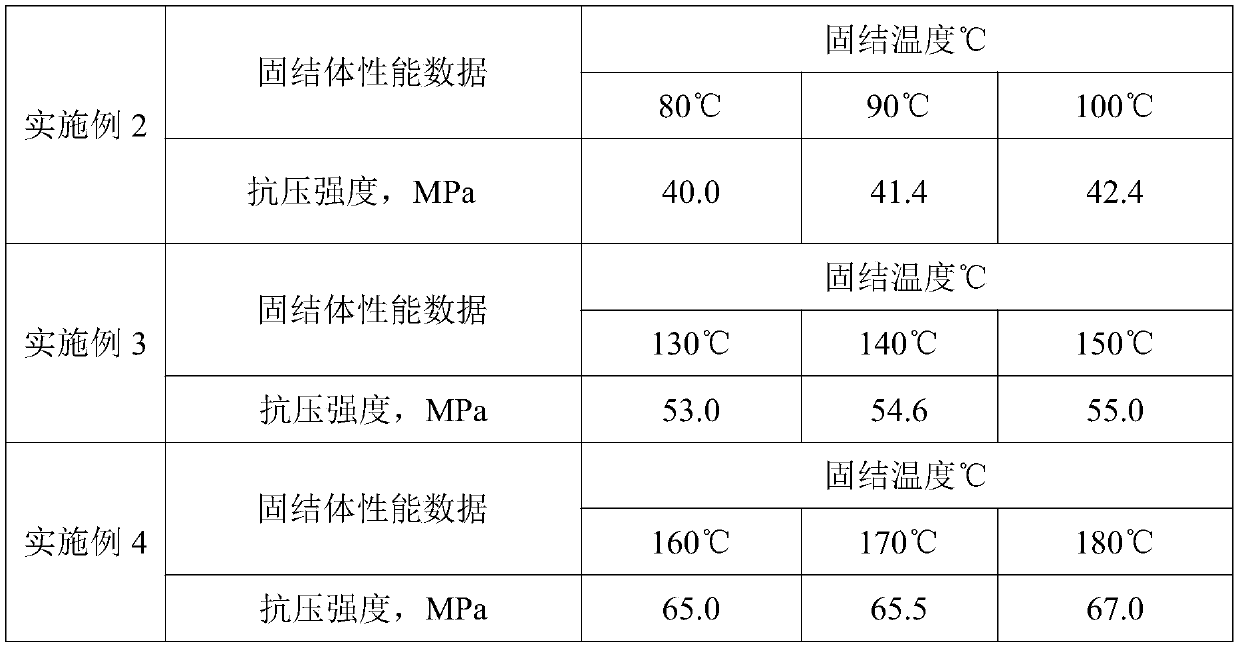

[0029]Inspection of consolidation strength: The prepared plugging agent consolidation body was measured for 12 hours at 80°C, 90°C, and 100°C for 12 hours at 80°C, 90°C, and 100°C without closure pressure. The compressive strength of the body varies from 40....

Embodiment 3

[0032] Fluorenyl epoxy resin (9,9-bis[(2,3-epoxypropoxy)phenyl]fluorene), epoxy resin E-51, basic phenolic resin F-51, solvent iso Propanol, coupling agent octadecyltrimethoxysilane, filler, modified calcium-based degasser, and curing agent are mixed according to the mass ratio of 20:12:12:21:5:20:5:5 to form a High-strength sealing and plugging agent. Wherein, the filler is a compound of superfine cement powder and PVA fiber in a mass ratio of 3:1. The curing agent is a mass ratio compound of benzophenone imine and 9,9 bis(4-aminophenyl)fluorene. The modified calcium-based degasser uses the degasser prepared in Example 1. The application temperature of the high-strength sealing and plugging agent is 150°C.

[0033] Inspection of consolidation strength: Measure the compressive strength of the prepared plugging agent consolidation body after curing at 130°C, 140°C, and 150°C for 12 hours at constant temperature without closing pressure. The compressive strength of the forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com