Magnesium alloy modified by in-situ magnesium hydroxide nano-sheet and preparation and application thereof

A magnesium hydroxide and nanosheet technology, applied in nanotechnology, nanomedicine, nanotechnology, etc., can solve the problem of bacterial inactivation and other problems, and achieve the effect of improving biocompatibility, improving antibacterial, and reducing corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

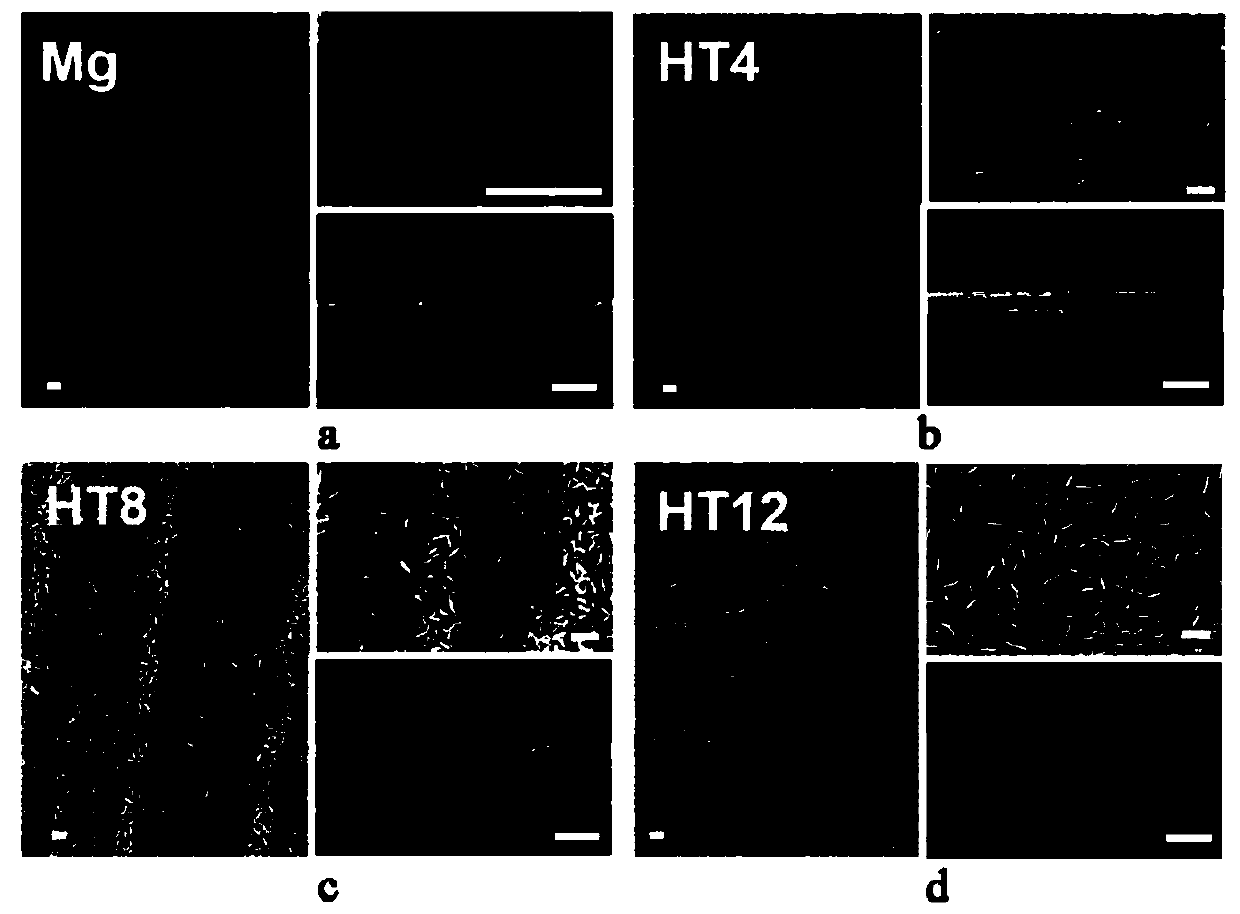

[0060] Polish and polish the magnesium sheets whose length, width and height are 10mm, 10mm and 5mm respectively, and clean them with alcohol. Put the sample into a 25mL reaction kettle, add 10mL of sodium hydroxide aqueous solution with pH = 12, tighten the reaction kettle and put it into the muffle furnace, the heating rate is 10°C min -1 , the reaction temperature was 120°C, and the reaction time was 4h, 8h and 12h. After the reaction, the microscopic morphology of the surface of each sample was observed by scanning electron microscope. Depend on figure 1 It can be seen that after 12 hours of hydrothermal reaction, a layer with an area of 1 μm is formed on the surface of the magnesium alloy. 2 , Magnesium hydroxide micro-nano sheets with a thickness of 5nm.

Embodiment 2

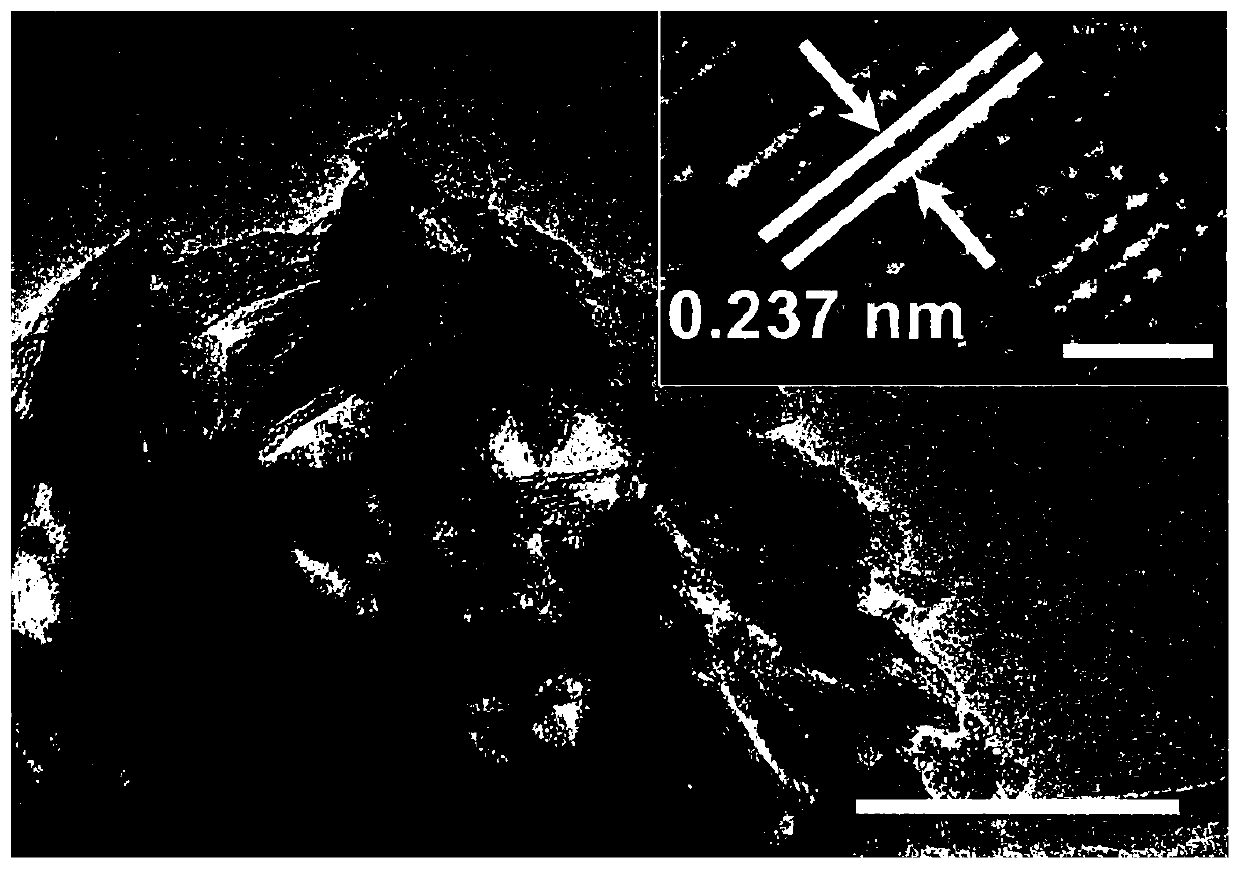

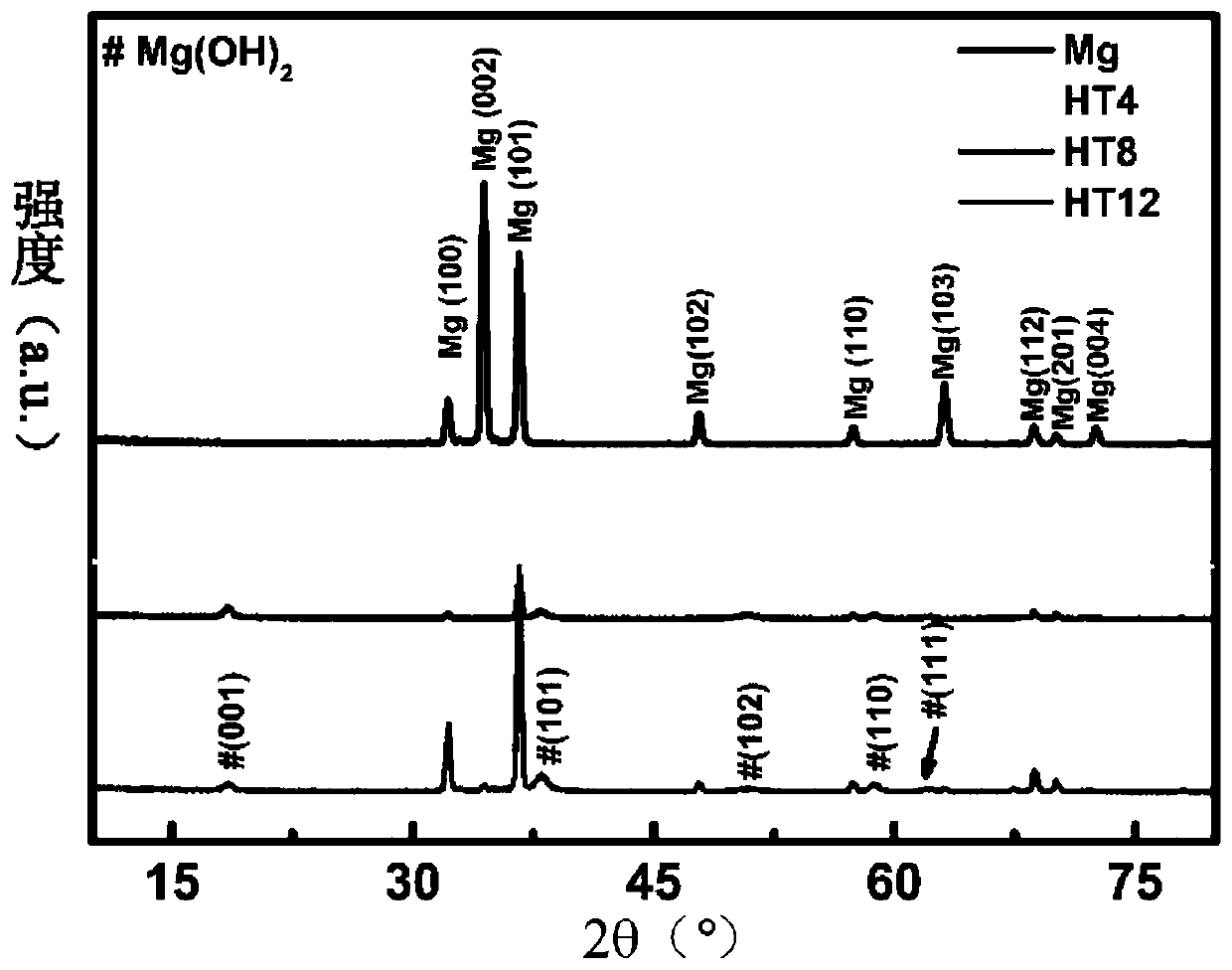

[0062] Crystallographic and chemical element analysis were performed on the surface of the sample treated in Example 1. High resolution TEM ( figure 2 ) results show that HT12 exists in the magnesium hydroxide crystal form of (101) crystal plane. XRD results ( image 3 ) can see the main peak of magnesium hydroxide. The XPS results showed that the conversion of Mg-Mg bonds to Mg-OH bonds would occur with the prolongation of treatment time ( Figure 4 ). The above results indicated that the hydrothermal reaction for 12 hours could obtain a layer of dense magnesium hydroxide nanosheets grown in situ.

Embodiment 3

[0064] The anticorrosion properties of the samples were analyzed by immersion method and electrochemical analysis method. There are many cracks on the surface of the untreated magnesium block after immersion, but no structural change occurs on the surface of the magnesium alloy modified by the magnesium hydroxide sheet ( Figure 5 ). The results of weight loss analysis showed that the weight loss of the magnesium alloy modified with nanosheets was significantly reduced compared with the bulk magnesium. Polarization curves show that the corrosion current decreases gradually with the prolongation of hydrothermal reaction time ( Image 6 ). Impedance spectroscopy showed that the longer the hydrothermal reaction time, the greater the impedance ( Figure 7 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com