Method for producing branched β-1,3-glucooligosaccharides by fermentation of mixed fungi

A technology of oligoglucan and dextran, which is applied in the fields of fermentation and microorganisms, can solve problems such as low hydrolysis rate, low feasibility, and pollution, and achieve the effects of uniform polymerization degree, low price, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

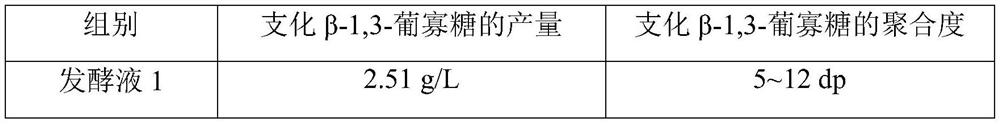

[0054] Example 1: Preparation of branched β-1,3-glucooligosaccharides

[0055] Specific steps are as follows:

[0056] Streak inoculation of Sclerotinia sclerotinum WSH-G01 capable of producing branched β-1,3-glucan on plate A, and culture at 25°C for 4 days to obtain hyphae of Sclerotinia sclerotinum WSH-G01 ;Pick 0.5g of mycelium of Sclerotinia sclerotinum WSH-G01 and inoculate it in seed medium A, and cultivate it at 30°C and 220rpm for 72h to obtain the seed liquid of Sclerotinia sclerotinum WSH-G01;

[0057] Trichoderma harzianum GIM 3.442, which can produce endo-β-1,3-glucanase, was streak-inoculated on plate C and cultured at 30°C for 3 days to obtain spores of Trichoderma harzianum GIM 3.442; The spores of Trichoderma twig GIM 3.442 were resuspended into spore liquid with 0.9% physiological saline; the spore liquid was mixed with 2.5×10 6 The inoculation amount of CFU / mL was inoculated in seed medium C, and cultured at 30°C and 200 rpm for 18 hours to obtain the seed...

Embodiment 2

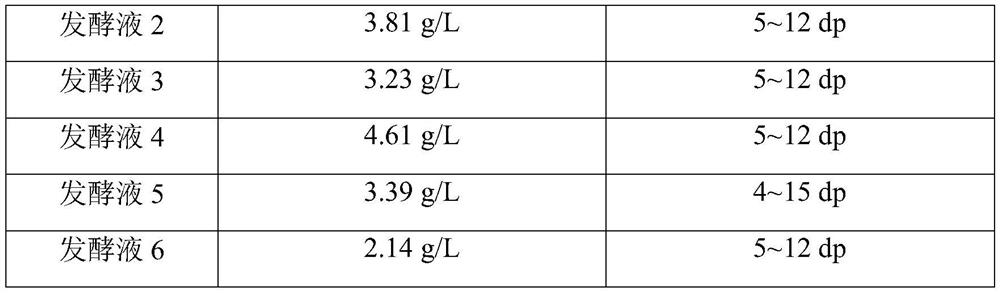

[0059] Example 2: Preparation of branched β-1,3-glucooligosaccharides

[0060] Specific steps are as follows:

[0061] Streak inoculation of Sclerotinia sclerotinum WSH-G01 capable of producing branched β-1,3-glucan on plate A, and culture at 25°C for 4 days to obtain hyphae of Sclerotinia sclerotinum WSH-G01 ;Pick 0.5g of mycelium of Sclerotinia sclerotinum WSH-G01 and inoculate it in seed medium A, and cultivate it at 30°C and 220rpm for 72h to obtain the seed liquid of Sclerotinia sclerotinum WSH-G01;

[0062] Trichoderma harzianum GIM 3.442, which can produce endo-β-1,3-glucanase, was streak-inoculated on plate C and cultured at 30°C for 3 days to obtain spores of Trichoderma harzianum GIM 3.442; The spores of Trichoderma twig GIM 3.442 were resuspended into spore liquid with 0.9% physiological saline; the spore liquid was mixed with 5×10 7 The inoculation amount of CFU / mL was inoculated in seed medium C, and cultured at 30°C and 200 rpm for 18 hours to obtain the seed l...

Embodiment 3

[0064] Example 3: Preparation of branched β-1,3-glucooligosaccharides

[0065] Specific steps are as follows:

[0066] Streak inoculation of Sclerotinia sclerotinum WSH-G01 capable of producing branched β-1,3-glucan on plate A, and culture at 25°C for 4 days to obtain hyphae of Sclerotinia sclerotinum WSH-G01 ;Pick 0.5g of mycelium of Sclerotinia sclerotinum WSH-G01 and inoculate it in seed medium A, and cultivate it at 30°C and 220rpm for 72h to obtain the seed liquid of Sclerotinia sclerotinum WSH-G01;

[0067] Trichoderma harzianum GIM 3.442, which can produce endo-β-1,3-glucanase, was streak-inoculated on plate C and cultured at 30°C for 3 days to obtain spores of Trichoderma harzianum GIM 3.442; The spores of Trichoderma twig GIM 3.442 were resuspended into spore liquid with 0.9% normal saline; the spore liquid was mixed with 1×10 7The inoculation amount of CFU / mL was inoculated in seed medium C, and cultured at 30°C and 200 rpm for 18 hours to obtain the seed liquid of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com