Grouting forming device and method for ITO rotating target

A technology of grouting molding and rotating target, which is applied in the direction of unloading device, ceramic molding machine, auxiliary molding equipment, etc. It can solve the problems of unstable target quality, uneven green body density, affecting product quality, etc., and achieve consistency Good, high yield, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Prepare ITO slurry, ITO powder prepared by chemical coprecipitation method, add dispersant PEG and binder PVA in deionized water, the amount of dispersant PEG is 1.0% of the mass fraction of the powder, and the amount of binder PVA The mass fraction of the powder is 1.5%, adding ammonia water to adjust the pH value to 10.3, adding the defoamer n-octanol, mixing evenly, pouring into the ITO powder, and then ball milling for 24 hours. The actual solid content of the slurry is 84.5%, and the viscosity is 26.8mpa.s.

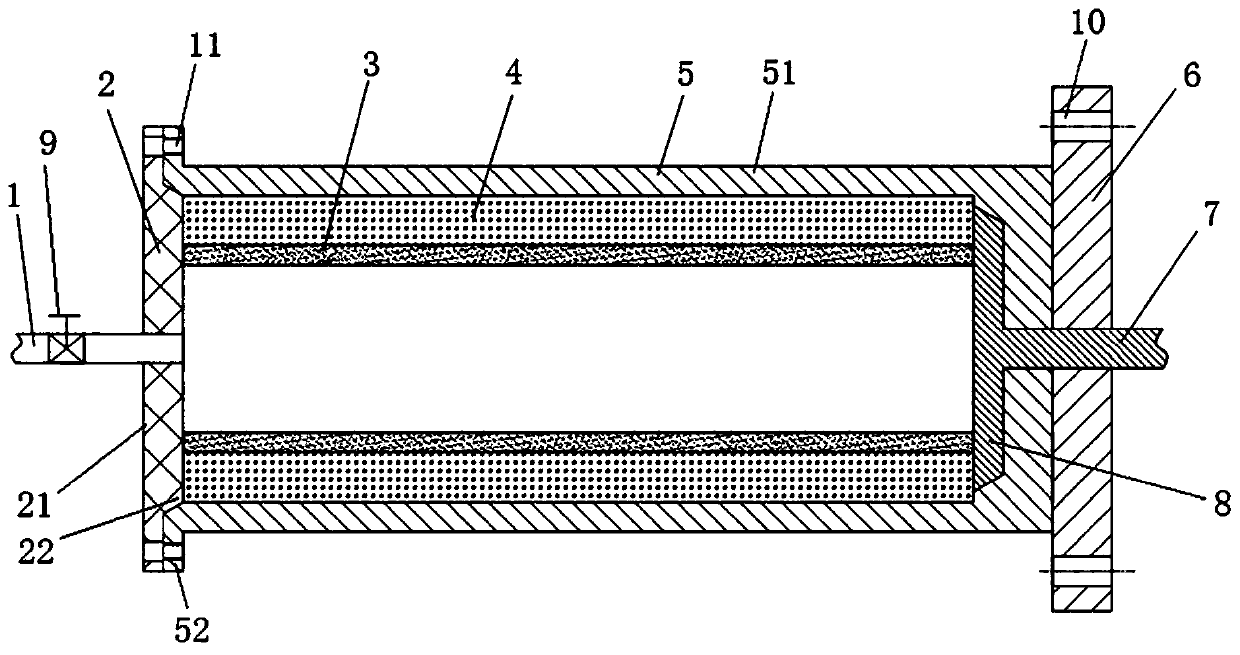

[0068] The size of the inner mold is 156mm×400mm. The inner mold, outer mold, sealing end cap and pushing mechanism of the mold are assembled and connected to the rotating mechanism. Open the feed valve on the slurry delivery pipeline and quickly inject 10.9kg of slurry. Time 16s, close the feed valve. Turn on the inverter of the rotating mechanism, adjust the speed to 1800r / min, take 26s, keep the speed to rotate steadily for 10 minutes, gradually reduce the...

Embodiment 2

[0070] Prepare ITO slurry, ITO powder prepared by chemical coprecipitation method, add dispersant PEG and binder PVA in deionized water, the amount of dispersant PEG is 1.2% of the mass fraction of the powder, and the amount of binder PVA The mass fraction of the powder is 1.8%, adding ammonia water to adjust the pH value to 10.5, adding the defoamer n-octanol, mixing evenly, pouring into the ITO powder, and then ball milling for 24 hours. The actual solid content of the slurry is 83.8%, and the viscosity is 28.2mpa.s.

[0071] The size of the inner mold is 212mm×400mm. The inner mold, outer mold, sealing end cap and pushing mechanism of the mold are assembled and connected to the rotating mechanism. Open the feed valve on the slurry delivery pipeline and quickly inject 20.8kg of slurry. Time 23s, close the feed valve. Turn on the frequency converter of the rotating mechanism, adjust the speed to 1500r / min, take 24s, keep the speed to rotate steadily for 10 minutes, gradually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com