High-crystallinity heat-resistant polylactic acid preparation method and apparatus

A technology with high crystallinity and preparation equipment, which is applied in the field of polylactic acid preparation, can solve the problems of limiting the application of polylactic acid, long molding time, and harsh conditions, so as to reduce the possibility of contamination, increase the speed of preparation, and increase the reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

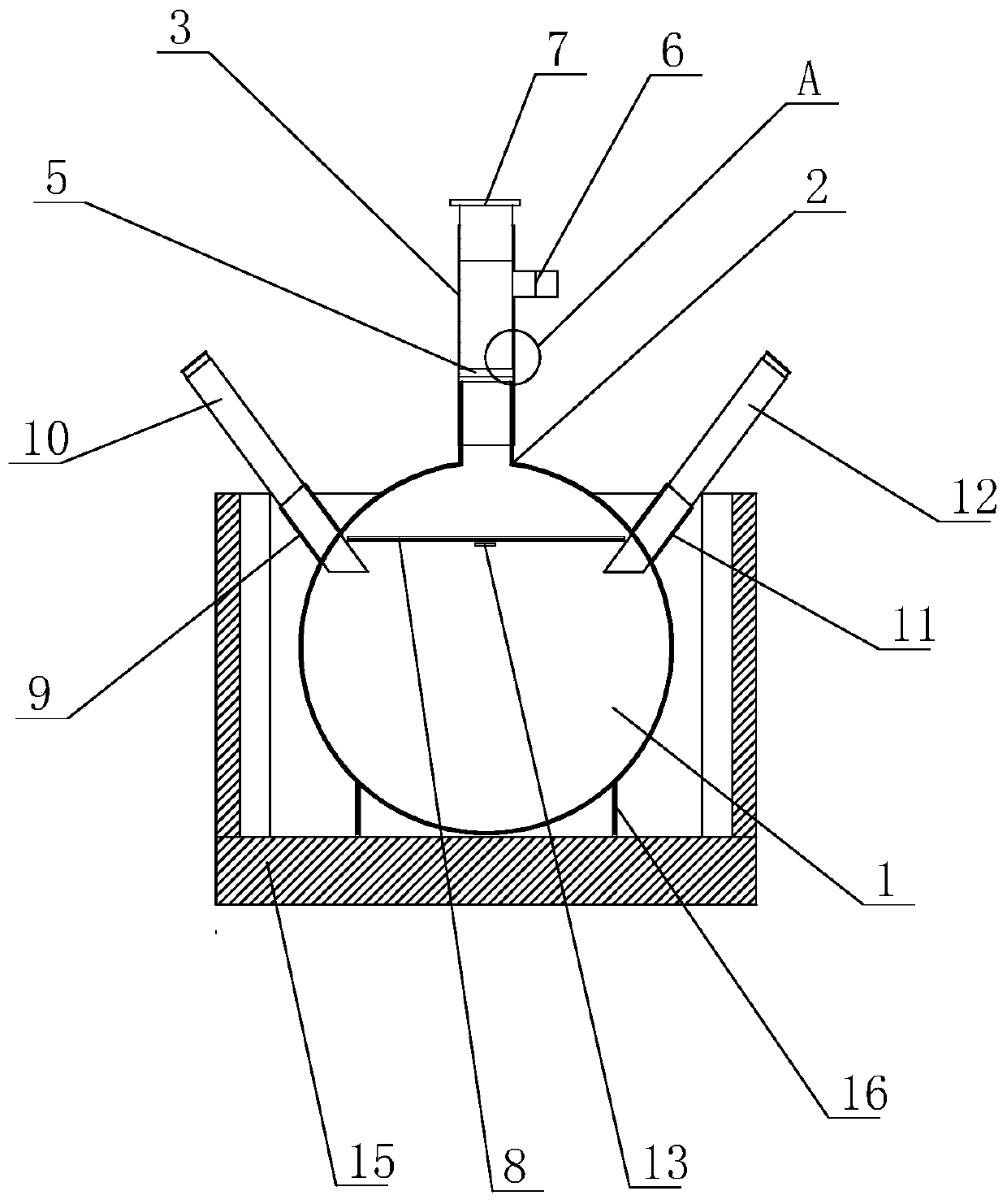

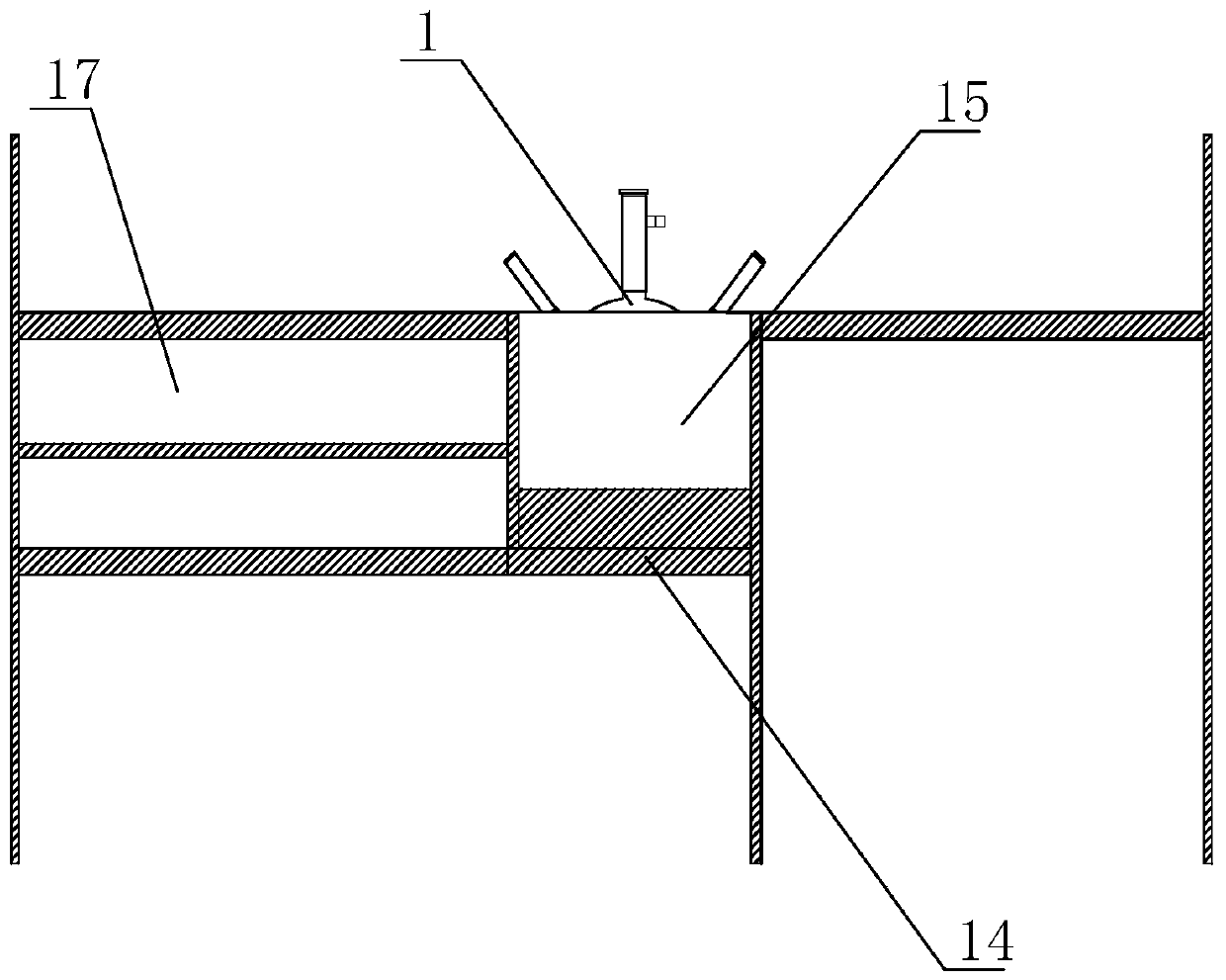

[0041] A method for preparing heat-resistant polylactic acid with high crystallinity, comprising the following steps:

[0042] Step 1: Add 100ml of dichloromethane to 15g of D-lactide in the spherical bottle body 1 to form a D-lactide solution with a molar concentration of 0.7mol / L, according to the molar ratio of D-lactide and initiator The initiator is added at a ratio of 12:1, wherein the initiator is any one of aluminum isopropoxide, potassium tert-butoxide, polyethylene glycol monomethyl ether or dipentaerythritol.

[0043] Then add the catalyst, the molar ratio of the catalyst to the initiator is 0.1:1, and the vacuum degree is 40-80 Pa under the reduced pressure state, and the microwave irradiation with a power of 200 watts makes it undergo ring-opening polymerization reaction, and the catalyst includes Catalyst I , Catalyst Ⅱ, catalyst Ⅰ is stannous octoate, stannous acetate, Sn(Oct) 2 、Sn(OBu) 2 、Fe(OEt) 3 Any one or more of them; Catalyst II is a titanium-tin comp...

Embodiment 2

[0056] A method for preparing heat-resistant polylactic acid with high crystallinity, comprising the following steps:

[0057] Step 1: Add 69.4ml of dichloromethane to 10gL-lactide to form an L-lactide solution with a molar concentration of 1mol / L, according to the molar ratio of L-lactide and initiator as 100:1 The initiator is added in proportion, wherein the initiator is any one of aluminum isopropoxide, potassium tert-butoxide, polyethylene glycol monomethyl ether or dipentaerythritol.

[0058] Then choose argon or nitrogen as the protective gas, and under the condition that the pressure of argon or nitrogen is 100-101325 Pa, add the catalyst, the molar ratio of the catalyst and the initiator is 0.25:1, and the power is 800 watts of microwave irradiation. It occurs ring-opening polymerization reaction, the catalyst includes catalyst I, catalyst II, and catalyst I is stannous octoate, stannous acetate, Sn(Oct) 2 、Sn(OBu) 2 、Fe(OEt) 3 Any one or more of them; Catalyst II ...

Embodiment 3

[0066] A method for preparing heat-resistant polylactic acid with high crystallinity, comprising the following steps:

[0067] Step 1: Add 100ml of dichloromethane to 15gL-lactide to form an L-lactide solution with a molar concentration of 0.7mol / L. According to the molar ratio of L-lactide and initiator, it is 6:1 The initiator is added in proportion, wherein the initiator is any one of aluminum isopropoxide, potassium tert-butoxide, polyethylene glycol monomethyl ether or dipentaerythritol.

[0068] Then place it under a reduced pressure state of 60 Pa Pa or under the protection of an inert gas, add a catalyst, the molar ratio of the catalyst to the initiator is 0.15:1, and microwave irradiation with a power of 600 watts makes it undergo ring-opening polymerization. Said catalyst includes catalyst I and catalyst II, and catalyst I is stannous octoate, stannous acetate, Sn(Oct) 2 、Sn(OBu) 2 、Fe(OEt) 3 Any one or more of them; Catalyst II is a titanium-tin composite catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com